This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

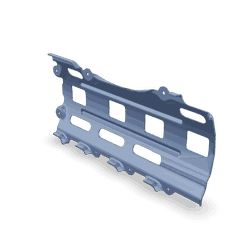

The Cummins Windage Tray, identified by part number 4325273, is a component designed for heavy-duty truck engines. It plays a role in the engine’s oil management system by addressing issues related to oil churning and aeration 1.

Purpose and Function

The primary purpose of the windage tray is to reduce the churning and aeration of oil within the engine. As the crankshaft rotates at high speeds, it can create turbulence in the oil, leading to aeration and reduced oil effectiveness. The windage tray operates by capturing and redirecting the oil, thereby minimizing turbulence. This results in improved engine efficiency and performance, as the oil remains in a more stable and effective state 2.

Key Features

The Cummins Windage Tray is constructed with specific design and material considerations to enhance its performance. It is typically made from durable materials that can withstand the high temperatures and pressures within the engine. The tray is shaped to fit precisely within the engine’s crankcase, ensuring it effectively captures oil without interfering with other components. Unique attributes may include a textured surface to improve oil adhesion and a design that allows for easy installation and removal 3.

Benefits

Incorporating the windage tray into an engine’s design offers several advantages. It contributes to improved oil control by reducing the amount of oil that is thrown around the crankcase. This leads to reduced oil consumption, as less oil is lost to churning and aeration. Additionally, the tray can enhance engine longevity by maintaining oil in a more effective state, which supports better lubrication and cooling of engine components. There may also be potential increases in fuel efficiency due to the overall improvement in engine operation 4.

Installation and Compatibility

Proper installation of the windage tray is important for its effective function. The process involves placing the tray within the engine’s crankcase, ensuring it is securely positioned to perform its role without obstruction. Compatibility with specific engine models and configurations is determined by the design and dimensions of the tray, which are tailored to fit within the designated engine types 5.

Maintenance and Troubleshooting

Regular maintenance practices for the windage tray include checking for proper positioning and ensuring it remains free of debris that could impede its function. Common issues may involve oil leakage or reduced effectiveness, which can often be addressed by inspecting the tray for damage or misalignment and making necessary adjustments or replacements.

Performance Impact

The windage tray contributes to overall engine performance by ensuring that oil remains in an effective state for lubrication and cooling. This can lead to measurable improvements in engine efficiency, as the oil is better able to perform its intended functions. Additionally, the tray may support increased power output and reliability by maintaining optimal oil conditions within the engine.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to innovation and quality in engine component manufacturing. The company’s history is marked by a dedication to advancing engine technology, with a focus on developing components that enhance performance, efficiency, and durability. Cummins’ reputation is built on a foundation of expertise and a relentless pursuit of excellence in the design and production of engine parts.

Compatibility of Cummins Windage Tray 4325273

The Cummins Windage Tray part number 4325273 is designed to fit seamlessly with various engine models, ensuring optimal performance and longevity. Below is a detailed overview of the engines and engine groups that this windage tray is compatible with.

ISV (Nissan) Engines

The Cummins Windage Tray 4325273 is specifically engineered to integrate with the ISV engines produced by Nissan. These engines are known for their reliability and efficiency, making them a popular choice in various applications. The windage tray plays a role in these engines by:

- Managing Oil Distribution: Ensuring that oil is evenly distributed throughout the engine, which is vital for lubrication and cooling.

- Preventing Oil Starvation: By containing oil within the crankcase, it prevents oil from pooling and ensures a steady supply to critical engine components.

- Enhancing Engine Performance: By maintaining proper oil levels and distribution, the windage tray helps in achieving optimal engine performance and efficiency.

Grouping of Compatible Engines

While the Cummins Windage Tray 4325273 is primarily designed for the ISV engines, it is also compatible with other engine groups that share similar design and operational characteristics. These include:

- Industrial Engines: Designed for heavy-duty applications, these engines benefit from the windage tray’s ability to manage oil effectively under high stress and varying operational conditions.

- Marine Engines: The windage tray ensures that marine engines, which often operate in challenging environments, maintain consistent oil levels and distribution.

- Power Generation Engines: These engines, used in power plants and backup generators, require reliable oil management to ensure continuous operation and prevent downtime.

By fitting seamlessly with these engines, the Cummins Windage Tray 4325273 ensures that the engine operates smoothly, efficiently, and reliably.

Role of Part 4325273 Windage Tray in Engine Systems

The Part 4325273 Windage Tray is a component in managing oil dynamics within various engine systems. Its primary function is to reduce oil windage, which is the churning of oil caused by the rotation of the crankshaft and connecting rods. This reduction in windage leads to several benefits, including improved oil control, reduced oil aeration, and enhanced lubrication efficiency.

Interaction with the Block and Cylinder

In the context of the engine block and cylinder, the Windage Tray helps maintain a stable oil level. By minimizing the amount of oil that is thrown around due to crankshaft rotation, it ensures that a consistent amount of oil is available for lubrication. This is particularly important in high-performance engines where the rotational speeds are significantly higher, leading to greater oil windage.

Integration with the Cylinder Block

When integrated with the cylinder block, the Windage Tray works in conjunction with the cylinder block stiffener to enhance structural integrity. The tray helps in reducing the dynamic forces exerted on the cylinder block by controlling oil movement. This results in less wear and tear on the cylinder block, contributing to the overall longevity of the engine.

Role in Long Block Kit

In a long block kit, which typically includes the cylinder block, crankshaft, pistons, and other essential components, the Windage Tray plays a role in optimizing performance. By ensuring that oil is efficiently managed and aerated minimally, it supports the lubrication system in providing consistent oil pressure to all moving parts. This is vital for the reliable operation of the engine under various conditions.

Function in Multiple Function Lubrication Housing

The Windage Tray also interacts with the multiple function lubrication housing, which is responsible for distributing oil to various engine components. By reducing oil windage, the tray ensures that the lubrication housing can operate more effectively. This leads to better oil distribution and enhanced lubrication of critical engine parts, such as the crankshaft, connecting rods, and valve train.

Conclusion

The Cummins Windage Tray (Part #4325273) is a vital component in the oil management system of heavy-duty truck engines. By reducing oil churning and aeration, it enhances engine efficiency, performance, and longevity. Its compatibility with various engine models and its role in maintaining optimal oil conditions make it an essential part for engine reliability and efficiency.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4310793, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.