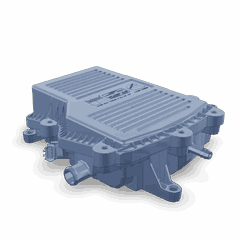

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The BREATHER, CRANKCASE, identified by part number 4312010, is a component manufactured by Cummins. This article provides an in-depth look at the functionality, purpose, and benefits of the Crankcase Breather in commercial trucks.

Basic Concepts of Crankcase Breather

A Crankcase Breather is a ventilation system component that allows air to enter and exit the crankcase of an engine. It helps manage pressure within the crankcase by releasing gases produced during the combustion process. This system prevents the buildup of pressure, which could lead to oil leaks and other engine issues 1.

Purpose and Role in Truck Operation

The 4312010 Crankcase Breather plays a role in maintaining the engine’s crankcase pressure by allowing the release of gases and vapors generated during engine operation. It ensures that the crankcase does not become over-pressurized, which could affect engine performance and lead to oil contamination 2.

Key Features

The 4312010 Crankcase Breather is designed with specific features to enhance its functionality:

- Constructed from durable materials to withstand the harsh conditions within the engine compartment.

- Engineered to efficiently vent crankcase gases while preventing the ingress of contaminants.

- Compatible with Cummins engines, ensuring optimal performance and integration.

Benefits

Incorporating the 4312010 Crankcase Breather into a truck’s engine system offers several benefits:

- Helps maintain optimal crankcase pressure, contributing to engine efficiency.

- Reduces the risk of oil leaks and contamination by managing crankcase gases.

- Enhances engine longevity by preventing excessive pressure buildup.

Troubleshooting and Maintenance

Regular maintenance and inspection of the Crankcase Breather are recommended to ensure its proper function:

- Check for signs of damage or wear that could affect its performance.

- Ensure that the breather is securely installed and free from obstructions.

- Clean or replace the breather as necessary to maintain efficient operation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a commitment to innovation and quality, Cummins provides reliable solutions for commercial vehicles, including a range of engine components like the 4312010 Crankcase Breather.

Compatibility with Cummins Engines

This Cummins part is compatible with several engine models, including:

- ISB CM2150, ISB6.7 CM2250, ISB6.7 CM2350 B101

- ISM CM876, ISM11 CM876 SN, QSM11 CM876

These engines are known for their robust performance and reliability, often used in heavy-duty and medium-duty applications. The breather ensures that the crankcase remains sealed and that the pressure within the engine is maintained at optimal levels, preventing oil contamination and ensuring smooth engine operation 3.

Role of Part 4312010 BREATHER,CRANKCASE in Engine Systems

In internal combustion engines, the BREATHER, CRANKCASE is integral to maintaining the health and efficiency of the engine. This component is designed to manage the pressure within the crankcase, ensuring that the engine operates smoothly and efficiently.

Pressure Regulation

The primary function of the BREATHER, CRANKCASE is to regulate the pressure inside the crankcase. As the pistons move up and down, they create pressure fluctuations. Without proper ventilation, these pressure changes can lead to oil leaks, reduced engine performance, and even catastrophic engine failure. The breather allows excess gases and vapors to escape, maintaining a stable pressure environment.

Contaminant Removal

Another significant role of the BREATHER, CRANKCASE is to remove contaminants from the crankcase. During engine operation, blow-by gases—which consist of unburned fuel, combustion byproducts, and moisture—can accumulate. These contaminants, if not expelled, can dilute the engine oil, leading to decreased lubrication efficiency and increased wear on engine components. The breather facilitates the removal of these harmful substances, preserving the integrity of the engine oil and enhancing the engine’s longevity.

Integration with PCV System

In many modern engines, the BREATHER, CRANKCASE is part of the Positive Crankcase Ventilation (PCV) system. The PCV system recirculates crankcase vapors back into the intake manifold, where they are burned during the combustion process. This not only reduces emissions but also ensures that the engine operates more cleanly and efficiently. The breather plays a vital role in this system by allowing the crankcase to vent while preventing the escape of harmful gases into the atmosphere.

Interaction with Oil System

The BREATHER, CRANKCASE also interacts closely with the engine’s oil system. By maintaining a consistent pressure within the crankcase, it helps ensure that the oil pump can effectively draw oil from the sump. This consistent oil flow is essential for lubricating moving parts, cooling the engine, and carrying away contaminants.

Enhanced Engine Performance

By performing these functions, the BREATHER, CRANKCASE contributes to overall engine performance. It helps maintain optimal pressure levels, removes contaminants, and works in tandem with the PCV system to ensure efficient operation. This results in smoother engine operation, improved fuel efficiency, and reduced emissions.

Conclusion

The BREATHER, CRANKCASE part 4312010 is a vital component in the engine system, playing a key role in pressure regulation, contaminant removal, and integration with the PCV system. Its proper function is essential for the engine’s performance, durability, and environmental compliance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.