This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Part #4019428 O-Ring is a component designed for use in commercial truck maintenance. This O-Ring serves a specific purpose within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its function and significance is important for maintaining the performance of commercial trucks.

Basic Concepts of O-Rings

O-Rings are circular elastomer seals that create a seal between two or more parts. They are widely used in mechanical systems to prevent leakage of fluids and gases. O-Rings function by deforming under compression, which allows them to fill gaps and create a tight seal. Their versatility and effectiveness make them a common choice in various applications, including automotive and industrial machinery 1.

Role of the 4019428 O-Ring in Truck Operation

The 4019428 O-Ring plays a role in the operation of commercial trucks by ensuring the integrity of seals within specific systems or components. It is associated with areas where fluid or gas containment is necessary to maintain system performance. The proper functioning of this O-Ring is important for the efficient operation of the truck, as it helps prevent leaks that could lead to system failures or reduced efficiency 2.

Key Features of the 4019428 O-Ring

This Cummins part is composed of materials that offer durability and resistance to various environmental factors. Its design characteristics, including size and flexibility, make it suitable for heavy-duty applications. The material composition ensures that the O-Ring can withstand the pressures and temperatures encountered in commercial truck operations, contributing to its longevity and reliability.

Benefits of Using the 4019428 O-Ring

Using the 4019428 O-Ring provides several advantages. It offers improved sealing efficiency, which helps maintain system performance and prevent leaks. Its durability ensures a longer service life, reducing the need for frequent replacements. Additionally, the O-Ring’s resistance to environmental factors, such as temperature extremes and chemical exposure, enhances its suitability for use in commercial trucks.

Installation Considerations

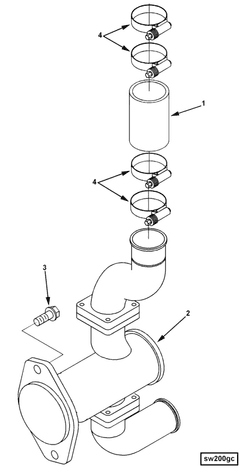

Proper installation of the 4019428 O-Ring is important to ensure optimal performance and longevity. Guidelines for installation include ensuring the O-Ring is the correct size for the application, using lubricants to facilitate placement, and avoiding damage to the O-Ring during installation. Careful attention to these details helps maintain the integrity of the seal and the overall system.

Troubleshooting Common Issues

Typical problems associated with O-Rings include leaks or failures, which can arise from improper installation, wear, or exposure to incompatible fluids. Troubleshooting steps may involve inspecting the O-Ring for signs of damage, ensuring it is correctly sized and installed, and checking for compatibility with system fluids. Addressing these issues promptly helps maintain system efficiency and prevent further complications.

Maintenance Tips

Regular maintenance practices can prolong the life of the 4019428 O-Ring and ensure continued reliable operation. These practices include periodic inspection for signs of wear or damage, cleaning the O-Ring and its seating area to remove contaminants, and replacing the O-Ring as part of routine maintenance schedules. Adhering to these recommendations helps maintain the integrity of the seal and the overall performance of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Cummins Engine Part 4019428 O-Ring Compatibility

The O-Ring part number 4019428, manufactured by Cummins, is designed to fit seamlessly within the engine systems of several Cummins diesel engines. This particular O-Ring is engineered to ensure a tight seal, preventing leaks and maintaining the integrity of the engine’s fluid systems.

QSC8.3 CM850 (CM2850) and QSM11 CM570

For the QSC8.3 CM850 (CM2850) and QSM11 CM570 engines, the O-Ring part 4019428 is integral to various components where sealing is critical. In these engines, the O-Ring is typically used in areas such as fuel injectors, coolant passages, and oil systems. Its placement in these regions ensures that there is no loss of pressure or contamination, which is vital for the engines’ performance and longevity.

The O-Ring’s material is selected for its durability and resistance to the high temperatures and pressures found within these engines. This ensures that the O-Ring maintains its sealing properties over extended periods, even under demanding operating conditions.

In the QSC8.3 CM850 (CM2850) and QSM11 CM570 engines, the O-Ring part 4019428 is used in several critical applications. For instance, it may be found in the fuel injection system, where it helps to maintain the integrity of the fuel delivery process. Additionally, it can be used in the coolant system to prevent leaks and maintain the proper coolant flow, which is essential for engine cooling.

The O-Ring’s precise fit and high-quality construction make it a reliable component in these engines. Its role in ensuring that the engine operates efficiently and safely cannot be overstated. The use of this O-Ring in the QSC8.3 CM850 (CM2850) and QSM11 CM570 engines highlights Cummins’ commitment to providing high-quality, durable parts that meet the rigorous demands of their diesel engines.

Role of Part 4019428 O-Ring in Engine Systems

The part 4019428 O-Ring is an essential component in various engine systems, particularly those involving fluid dynamics and sealing mechanisms. Its application spans across multiple pump systems and kits, ensuring efficient operation and preventing leaks.

Pump Systems

In pump systems, the 4019428 O-Ring is utilized to create a secure seal between moving and stationary parts. This seal is vital for maintaining the integrity of the pump’s performance by preventing fluid leakage and ensuring that the pump operates within its designed parameters.

Raw Water Systems

For raw water systems, the O-Ring is incorporated into the raw water pump, raw water pump major kit, raw water pump intermediate kit, and raw water pump minor kit. Its role here is to seal connections and joints, ensuring that raw water is efficiently circulated through the engine cooling system without any loss of pressure or fluid.

Sea Water Systems

In sea water systems, the 4019428 O-Ring is a component of the sea water pump, sea water pump major kit, and seawater pump major kit. Its function is to seal the pump housing and impeller, which is particularly important in marine environments where the pump is exposed to corrosive sea water. The O-Ring helps in maintaining the pump’s efficiency and longevity by preventing sea water from seeping into areas where it could cause damage.

Water Pump Kits

Across various water pump kits, the 4019428 O-Ring serves as a universal seal that adapts to different pump designs and applications. Whether it’s a major overhaul kit or a minor repair kit, the O-Ring ensures that all components within the kit function cohesively, providing a reliable seal that contributes to the overall performance and durability of the water pump system.

Conclusion

In summary, the 4019428 O-Ring plays a significant role in enhancing the functionality and reliability of engine systems by ensuring tight seals in pump and water systems, thereby contributing to the efficient operation of these components. Its durability, resistance to environmental factors, and precise fit make it a critical component in maintaining the performance and longevity of commercial trucks and diesel engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.