This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

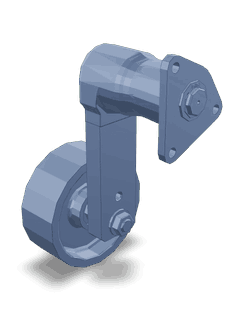

The Cummins 4009442 Idler Lever is a critical component designed for use in commercial trucks, specifically within the engine or transmission system. Understanding its function and significance is essential for maintaining and optimizing the truck’s performance.

Basic Concepts of Idler Levers

An idler lever is a mechanical component that facilitates the movement or redirection of force within a system. In the context of a truck’s engine or transmission, it typically adjusts or maintains tension in belts or chains, ensuring smooth operation of various engine components. The idler lever operates by pivoting on a fixed point, allowing it to change the direction of force applied by other moving parts 1.

Purpose of the Cummins 4009442 Idler Lever

The Cummins 4009442 Idler Lever is engineered to interact with other components within a truck’s engine or transmission system. Its role involves adjusting the tension of belts or chains, which is vital for the efficient transfer of power and the smooth operation of engine components. By maintaining proper tension, the idler lever contributes to the truck’s performance, ensuring that all parts work in harmony 2.

Key Features

This Cummins part is characterized by its robust design and the quality materials used in its construction. These features enhance its functionality and durability, allowing it to withstand the demanding conditions of commercial truck operation. The lever’s design ensures precise adjustment of tension, while the materials used contribute to its longevity and resistance to wear.

Benefits

The Cummins 4009442 Idler Lever offers several advantages, including improved efficiency and reliability in the truck’s engine or transmission system. By ensuring optimal tension in belts or chains, it helps to reduce wear on other components, leading to enhanced performance and longevity of the truck. Additionally, its design and materials contribute to the overall reliability of the truck’s system 3.

Installation and Integration

Installing the Cummins 4009442 Idler Lever requires careful attention to ensure proper integration into the truck’s system. The process involves aligning the lever with other components and securing it in place to allow for the correct operation of the engine or transmission. Specific considerations may include ensuring the correct tension is applied and that the lever is compatible with the truck’s existing system.

Troubleshooting and Maintenance

Common issues with the Cummins 4009442 Idler Lever may include wear or misalignment, which can affect the tension of belts or chains. Diagnostic tips for identifying these issues involve checking for signs of wear on the lever or other components and ensuring that the tension is within the manufacturer’s specifications. Regular maintenance practices, such as inspecting for wear and ensuring proper alignment, can help to ensure the longevity and optimal performance of the lever.

Compatibility and Application

The Cummins 4009442 Idler Lever is designed for use in specific types of trucks and engine models. Its application is tailored to meet the demands of commercial truck operation, ensuring compatibility with the truck’s engine or transmission system. Understanding the compatibility and specific applications for which the lever is designed is important for ensuring optimal performance and integration into the truck’s system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and performance is evident in its products, including the Cummins 4009442 Idler Lever, which is designed to meet the rigorous demands of commercial truck operation.

Application in Cummins Engines

K19 Engines

The Idler Lever part 4009442 is specifically engineered to integrate with the K19 engine series. Its role in this engine series is to maintain the proper tension and alignment of the timing belt or chain, ensuring that the engine’s internal components operate in harmony. This is crucial for the engine’s longevity and performance, as any misalignment can lead to increased wear and potential engine failure.

Other Cummins Engines

Beyond the K19 series, the Idler Lever part 4009442 is also compatible with a range of other Cummins engines. Its design allows it to fit into various engine configurations, providing the same essential function of maintaining proper tension and alignment. This versatility makes it a valuable component for technicians and engineers working with multiple Cummins engine models.

Importance of the Idler Lever

The Idler Lever’s primary function is to keep the engine’s timing components in check. By doing so, it helps prevent issues such as belt or chain slippage, which can cause significant damage to the engine. Its precise fit and reliable performance are critical for maintaining the engine’s efficiency and reliability.

Installation and Maintenance

Proper installation of the Idler Lever part 4009442 is essential to ensure it functions correctly. Technicians should follow the manufacturer’s guidelines for installation, which typically include aligning the idler lever with the engine’s timing components and securing it in place. Regular maintenance checks should be performed to ensure the idler lever remains in good condition and continues to perform its function effectively.

Role of Part 4009442 Idler Lever in Engine Systems

The 4009442 Idler Lever is an integral component in maintaining the efficiency and reliability of various engine systems. Its primary function is to regulate the tension in the belt system, ensuring optimal performance of connected components.

Interaction with Belt Tensioner

The Idler Lever works in conjunction with the Belt Tensioner to maintain the correct tension on the drive belt. This is essential for the smooth operation of the engine’s accessory drives. Proper tension ensures that the belt does not slip, which could lead to inefficient power transmission and potential damage to the belt or driven components.

Drive System Efficiency

In the drive system, the Idler Lever helps in adjusting the path of the belt, reducing wear and tear. By maintaining consistent tension and alignment, it ensures that the belt operates within its designed parameters, enhancing the durability and performance of the drive components.

Fan System Regulation

The Idler Lever also plays a significant role in the fan system. It assists in maintaining the appropriate tension on the belt that drives the fan, ensuring that the fan operates efficiently. This is particularly important in managing the engine’s cooling system, as the fan’s performance directly impacts the engine’s thermal regulation.

Conclusion

The Cummins 4009442 Idler Lever is a key component in ensuring the smooth and efficient operation of the belt-driven systems within an engine, contributing to the overall reliability and performance of the engine. Understanding its role, application, and maintenance is crucial for technicians and engineers to maintain and repair Cummins engines effectively.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.