This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

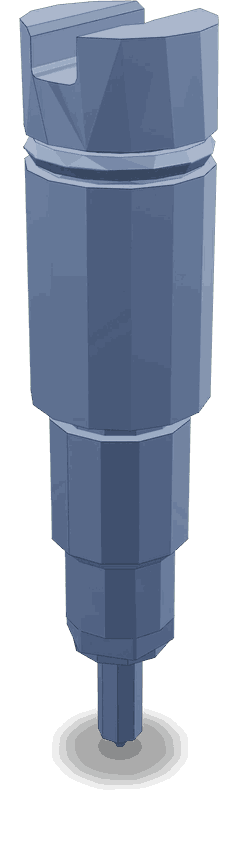

The Cummins 3948525 Injector is a component designed for use in commercial trucks, playing a significant role in the efficient operation of these vehicles. This injector is part of the fuel system, responsible for delivering fuel into the engine’s combustion chambers. Its design and functionality are essential for maintaining the performance and efficiency of the truck’s engine.

Basic Concepts of Fuel Injectors

Fuel injectors are components within an engine’s fuel system that deliver pressurized fuel into the combustion chambers. They operate by atomizing fuel into a fine mist, which mixes with air for combustion. The efficiency of this process directly impacts the engine’s performance, fuel economy, and emissions output. Fuel injectors must be precisely controlled to ensure optimal combustion, which is achieved through the use of electronic control units (ECUs) that regulate the timing and amount of fuel injected 1.

Purpose of the Cummins 3948525 Injector

The Cummins 3948525 Injector serves a specific function within the truck’s engine by delivering fuel in a manner that enhances combustion efficiency. It is designed to atomize fuel into the combustion chamber at the precise moment required for optimal engine performance. This injector contributes to the overall efficiency of the fuel delivery system, ensuring that the engine operates smoothly and efficiently.

Key Features

The Cummins 3948525 Injector is characterized by several key features that enhance its performance. Its design incorporates advanced materials and precision engineering to ensure durability and efficiency. The injector is built to withstand the high pressures and temperatures within the engine, ensuring reliable operation over time. Additionally, technological advancements in its design contribute to improved fuel atomization and combustion efficiency 2.

Benefits of Using the Cummins 3948525 Injector

Utilizing the Cummins 3948525 Injector in a truck’s engine system offers several advantages. These include improved fuel efficiency, as the injector ensures that fuel is delivered in a manner that maximizes combustion efficiency. This results in enhanced engine performance, with smoother operation and increased power output. Additionally, the precise fuel delivery contributes to reduced emissions, aligning with environmental regulations and promoting sustainable operation 3.

Installation and Integration

Installing the Cummins 3948525 Injector into a truck’s engine system requires careful consideration of the engine’s specific requirements. The injector must be properly aligned and secured to ensure optimal performance. Integration into the engine system involves connecting it to the fuel supply and electronic control unit (ECU), which regulates its operation. Proper installation is crucial for ensuring the injector functions as intended, contributing to the engine’s overall efficiency and performance.

Maintenance and Troubleshooting

Maintaining the Cummins 3948525 Injector is important for ensuring its longevity and optimal performance. Regular inspection and cleaning of the injector can prevent buildup and ensure smooth operation. Common issues that may arise include clogging or leaks, which can be addressed through proper maintenance practices. Troubleshooting tips include checking for proper fuel pressure and ensuring the injector is receiving the correct signals from the ECU.

Performance Impact

The Cummins 3948525 Injector has a notable impact on the overall performance of the truck. By ensuring precise fuel delivery, it contributes to increased power output and improved fuel efficiency. The injector’s role in the combustion process directly affects the engine’s performance, making it a critical component for achieving optimal operation. Additionally, its design helps in reducing emissions, contributing to a more environmentally friendly operation.

Technological Innovations

The Cummins 3948525 Injector incorporates several technological innovations that enhance its effectiveness. Precision engineering ensures that the injector delivers fuel with accuracy, while advanced materials contribute to its durability under high-pressure conditions. These innovations play a role in the injector’s ability to improve fuel efficiency, engine performance, and reduce emissions, demonstrating the importance of technological advancement in automotive components.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality components and commitment to innovation. With a history of producing reliable and efficient engines and components, Cummins has built a reputation for excellence. The company’s dedication to quality and performance is evident in its products, including the Cummins 3948525 Injector, which exemplifies the brand’s commitment to advancing automotive technology.

Cummins Injector 3948525 Compatibility

The Cummins Injector part number 3948525 is a critical component in the fuel injection system of various engines. This injector is designed to deliver fuel into the combustion chamber with precision, ensuring optimal engine performance and efficiency. Below is a detailed description of the compatibility of this injector with specific Cummins engines.

ISC CM554 Engine

The ISC CM554 engine is a high-performance, heavy-duty diesel engine widely used in various industrial and commercial applications. The Cummins Injector 3948525 is specifically engineered to fit seamlessly within the ISC CM554 engine’s fuel injection system. This injector ensures that the engine operates at peak efficiency by providing the correct fuel delivery at the right time, which is crucial for maintaining power output and fuel economy.

Grouping of Compatible Engines

While the ISC CM554 engine is a notable example, the Cummins Injector 3948525 is also compatible with a range of other Cummins engines. These engines share similar design principles and operational requirements, making the injector a versatile component across multiple engine models. The compatibility of this injector with other engines ensures that it can be used in various applications, providing a reliable and efficient fuel delivery system.

The Cummins Injector 3948525 is a testament to the brand’s commitment to quality and performance, ensuring that it meets the stringent demands of modern diesel engines.

Role of Part 3948525 Injector in Engine Systems

The injector, specifically part 3948525, is integral to the efficient operation of engine systems. It works in conjunction with several key components to ensure optimal performance and fuel efficiency.

Fuel Rail Integration

The injector is mounted on the fuel rail, a component that distributes pressurized fuel to each injector. The fuel rail maintains consistent pressure, allowing the injector to deliver precise amounts of fuel into the combustion chamber.

Engine Control Unit (ECU) Communication

The injector operates under the command of the Engine Control Unit (ECU). The ECU monitors various parameters such as engine load, RPM, and air-fuel ratio to determine the precise timing and duration of fuel injection. This ensures that the engine receives the correct amount of fuel for efficient combustion.

Combustion Chamber Interaction

Once the ECU signals the injector to open, fuel is sprayed into the combustion chamber. The design of the injector nozzle ensures that fuel is atomized into fine particles, promoting better mixing with air and more complete combustion.

Throttle Body and Air Intake System

The injector works in tandem with the throttle body and air intake system. As air enters the engine through the throttle body, the injector releases fuel in a measured quantity. This air-fuel mixture is then compressed and ignited by the spark plug, driving the piston downward.

Oxygen Sensor Feedback

The injector’s operation is also influenced by feedback from the oxygen sensor. This sensor measures the amount of unburned oxygen in the exhaust gases, providing data to the ECU. The ECU uses this information to adjust the fuel injection timing and quantity, ensuring that the air-fuel ratio remains optimal.

Exhaust Gas Recirculation (EGR) System

In engines equipped with an EGR system, the injector must adapt to the recirculated exhaust gases mixed with the intake air. This requires the injector to fine-tune fuel delivery to maintain efficient combustion despite the altered air composition.

Fuel Pump and Filter

The injector relies on a consistent supply of clean, pressurized fuel from the fuel pump and filter. The fuel pump pressurizes the fuel, while the filter removes impurities, ensuring that the injector operates smoothly and efficiently.

By understanding how part 3948525 injector interacts with these components, engineers and mechanics can better diagnose issues and optimize engine performance.

Conclusion

The Cummins 3948525 Injector is a critical component in the fuel injection system of various engines, designed to deliver fuel into the combustion chamber with precision. Its compatibility with engines like the ISC CM554 and other Cummins models ensures optimal engine performance and efficiency. The injector’s role in engine systems, including its integration with the fuel rail, ECU communication, and interaction with the combustion chamber, underscores its importance in maintaining engine efficiency and performance. Regular maintenance and proper installation are essential for ensuring the longevity and optimal operation of this part.

-

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.