3917749

Vibration Isolator

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3917749 Vibration Isolator is engineered to reduce the transmission of vibrations from the engine to the truck’s frame and other components. This part is instrumental in ensuring the smooth operation of commercial trucks by enhancing ride comfort and protecting various truck components from excessive vibrations.

Basic Concepts of Vibration Isolators

Vibration isolators are devices that reduce the transmission of vibrations between mechanical systems by absorbing or dampening vibrational energy. In the automotive industry, these components are crucial for maintaining vehicle integrity and performance by minimizing the impact of engine vibrations on the vehicle’s structure and components 1.

Purpose of the Cummins 3917749 Vibration Isolator

The Cummins 3917749 Vibration Isolator is designed to reduce vibrations transmitted from the engine to the truck’s frame and other components. This reduction helps maintain the structural integrity of the truck, enhances ride comfort for the driver and passengers, and reduces wear and tear on various truck components.

Key Features

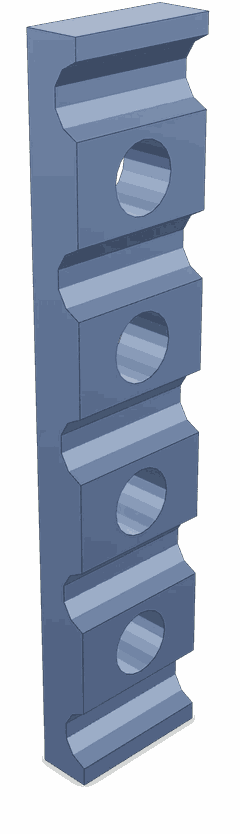

The Cummins 3917749 Vibration Isolator features a robust design incorporating high-quality materials to ensure durability and efficiency. Its construction includes elements that enhance vibration dampening capabilities, providing reliable performance in demanding commercial truck environments.

Benefits of Using the Cummins 3917749 Vibration Isolator

Incorporating this Cummins part into truck designs offers several advantages, including improved ride comfort due to reduced vibrations, decreased wear and tear on truck components, and enhanced engine performance by ensuring a stable engine mount. Additionally, it contributes to the overall longevity of the truck by protecting critical components from the adverse effects of engine vibrations 2.

Installation and Integration

Proper installation of the Cummins 3917749 Vibration Isolator is crucial for its optimal performance. Guidelines for installation should be followed to ensure that the isolator is correctly positioned and secured within the truck’s engine system. Correct installation ensures the effectiveness of the isolator and contributes to the overall performance and safety of the truck.

Troubleshooting and Maintenance

Common issues with the Cummins 3917749 Vibration Isolator may include wear and tear or damage due to extreme conditions. Regular inspection and maintenance are recommended to ensure its longevity and efficient operation. Troubleshooting steps may involve checking for signs of wear, ensuring proper installation, and replacing the isolator if necessary.

Performance and Efficiency

The Cummins 3917749 Vibration Isolator contributes to the overall performance and efficiency of a truck by reducing engine vibrations. This can lead to improved fuel efficiency, enhanced engine longevity, and increased driver comfort. By mitigating the effects of vibrations, the isolator plays a role in maintaining the truck’s performance and reliability over time 3.

Integration with Engine Components

Integration with Camshaft

When integrated with the camshaft, the Vibration Isolator effectively reduces the vibrational energy transmitted from the camshaft to the engine block. This reduction in vibration leads to more consistent valve timing and improved overall engine performance. The isolator absorbs the high-frequency vibrations generated during the camshaft’s operation, ensuring that these vibrations do not adversely affect other engine components.

Interaction with Fuel Plumbing

In fuel systems, the Vibration Isolator is employed to stabilize the fuel lines, particularly the fuel plumbing. By isolating vibrations, it prevents the fuel lines from experiencing undue stress, which can lead to cracks or leaks. This stabilization ensures a consistent fuel supply, which is vital for maintaining engine efficiency and reliability.

Role in Injector Fuel Supply Tube

The injector fuel supply tube benefits significantly from the Vibration Isolator. By minimizing vibrations, the isolator ensures that the fuel supply tube remains securely in place and operates efficiently. This stability is essential for precise fuel delivery to the injectors, directly impacting the engine’s combustion process and overall performance.

Application in Injector Plumbing

Injector plumbing systems are particularly sensitive to vibrations. The Vibration Isolator plays a key role in protecting these systems by absorbing vibrational energy. This protection ensures that the injector plumbing remains intact and functions optimally, contributing to consistent fuel injection and enhanced engine performance.

Enhancement of Performance Parts

Incorporating the Vibration Isolator into performance parts, such as aftermarket camshafts or high-flow fuel systems, further amplifies their effectiveness. By reducing vibrations, the isolator allows these performance parts to operate at their peak efficiency without the detrimental effects of excessive vibration. This results in improved engine responsiveness, power output, and longevity of the performance components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and quality, Cummins is committed to providing reliable and efficient products for the automotive and engine manufacturing industry. Their vibration isolators, including the Cummins 3917749, are designed with a focus on performance, durability, and compatibility with various engine models and truck types 4.

Conclusion

The Cummins 3917749 Vibration Isolator is a vital component in the operation of commercial trucks, offering significant benefits in terms of ride comfort, component protection, and engine performance. Its robust design and integration with various engine components ensure that it plays a crucial role in maintaining the overall efficiency and reliability of the vehicle.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.