This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

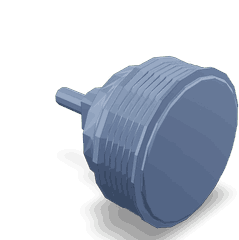

The Idler Top Level Assembly Pulley, part number 3680196, is a component manufactured by Cummins, a prominent entity in the automotive and heavy-duty truck industry. This pulley is essential for the efficient operation of heavy-duty trucks, contributing significantly to the engine system’s functionality. Cummins’ reputation for quality and innovation ensures that this pulley meets the stringent requirements of heavy-duty applications.

Basic Concepts

Idler pulleys are fundamental in belt-driven systems, maintaining the proper tension and alignment of belts. They do not directly drive any component but are crucial for ensuring optimal contact between belts and driven/driving pulleys. This maintenance is vital for efficient power transfer and smooth operation of mechanical systems 1.

Functionality of Idler Top Level Assembly Pulley

The Idler Top Level Assembly Pulley operates within the truck’s engine system by interacting with belts that drive components such as the alternator, water pump, and air conditioning compressor. Its primary function is to maintain proper belt tension and alignment, contributing to the efficient operation of these components. By ensuring belts run true and do not slip, the pulley enhances the engine system’s reliable performance 2.

Role in Truck Operation

In truck operation, the Idler Top Level Assembly Pulley significantly contributes to the engine’s overall performance and efficiency. Proper belt tension and alignment are crucial for the consistent operation of engine-driven accessories, affecting the truck’s performance, fuel efficiency, and reliability. The pulley’s role in maintaining these parameters is integral to the truck’s operation 3.

Key Features

The Idler Top Level Assembly Pulley is characterized by several key features that enhance its performance. These include a robust material composition designed to withstand heavy-duty truck operation, a precision-engineered design for optimal belt contact, and a durable bearing system that reduces friction and wear. These features collectively contribute to the pulley’s effectiveness and longevity.

Benefits

The advantages provided by the Idler Top Level Assembly Pulley are manifold. Improved belt tension leads to more efficient power transfer and reduced slippage, minimizing wear on belts and driven components. Additionally, the pulley’s enhanced durability means longer service intervals and reduced maintenance costs, contributing to the truck’s overall efficiency and reliability.

Troubleshooting and Maintenance

Common issues with the Idler Top Level Assembly Pulley include wear on the pulley surface, misalignment, and bearing failure. Regular inspection and maintenance are recommended to ensure the pulley remains in optimal condition. This includes checking for proper belt tension, ensuring correct alignment, and inspecting bearings for signs of wear or damage. Addressing these issues promptly can prevent more significant problems and ensure the truck’s continued efficient operation.

About Cummins

Cummins is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industries. Their commitment to producing high-quality components is evident in the design and manufacturing of the Idler Top Level Assembly Pulley, ensuring it meets the rigorous demands of heavy-duty applications.

Idler Top Level Assembly Pulley (Part 3680196) in Cummins Engines

The Idler Top Level Assembly Pulley (Part 3680196) is a critical component in the engine systems of various Cummins engines, including the ISX CM570. This part plays a pivotal role in the engine’s operation by ensuring the proper alignment and tension of the engine’s belt system.

ISX CM570

In the ISX CM570 engine, the Idler Top Level Assembly Pulley is designed to maintain the correct tension of the serpentine belt, which drives essential engine accessories such as the alternator, water pump, and air conditioning compressor. This pulley works in conjunction with other components to ensure that these accessories operate efficiently and reliably.

Other Cummins Engines

Similarly, in other Cummins engines, the Idler Top Level Assembly Pulley (Part 3680196) is engineered to perform the same function. It is integral to the belt routing system, ensuring that the belt remains properly aligned and tensioned. This helps to prevent slippage and reduces wear on the belt and driven components, thereby extending the overall lifespan of the engine’s accessories and maintaining optimal engine performance.

The design and placement of this pulley are crucial for the engine’s balance and efficiency. It is typically positioned at the top level of the engine, hence the name, and is constructed to withstand the high stresses and temperatures present in the engine compartment.

Role of Part 3680196 Idler Top Level Assembly Pulley in Engine Systems

The Part 3680196 Idler Top Level Assembly Pulley is integral to the efficient operation of various engine components. It primarily functions to maintain the proper tension in the serpentine belt system, ensuring that all driven components receive the necessary power transmission from the engine.

Interaction with the Alternator Mounting System

When integrated into an engine system that includes an alternator, the Idler Top Level Assembly Pulley works in conjunction with the alternator mounting to optimize belt tension. This ensures that the alternator, which is responsible for generating electrical power to charge the battery and power the vehicle’s electrical systems, operates within its designed parameters. Proper tension provided by the idler pulley prevents slippage of the belt, which could lead to inefficient power transfer and potential overheating of the alternator.

Ensuring Smooth Operation of Accessory Drives

Beyond the alternator, the idler pulley plays a significant role in the smooth operation of other accessory drives such as the power steering pump, air conditioning compressor, and water pump. By maintaining consistent belt tension, it helps these components function efficiently, reducing wear and tear and enhancing the longevity of the belt and the driven components.

Contribution to Engine Efficiency

The efficient operation of the Idler Top Level Assembly Pulley contributes to overall engine efficiency. By ensuring that all accessory drives are properly tensioned, it helps minimize energy loss in the belt drive system. This not only enhances the performance of individual components but also contributes to the engine’s fuel efficiency and reduces the load on the crankshaft.

Support in Variable Systems

In engines equipped with variable systems such as variable valve timing or variable displacement, the Idler Top Level Assembly Pulley’s role becomes even more significant. These systems rely on precise belt tension to operate effectively, and the idler pulley ensures that the belt maintains the necessary tension across a range of engine speeds and loads.

Conclusion

The Idler Top Level Assembly Pulley (Part 3680196) is a key component in the engine’s accessory drive system, playing a vital role in maintaining belt tension and ensuring the efficient operation of driven components such as the alternator, power steering pump, air conditioning compressor, and water pump. Its robust design, precision engineering, and durable construction make it an essential part of Cummins engines, contributing to their overall performance, efficiency, and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.