This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3534109 Thrust Collar, a component manufactured by Cummins, is designed to enhance the operation of commercial trucks. This overview explores the specifics of this Cummins part, its purpose, and its integration into the engine system of commercial trucks.

Basic Concepts of Thrust Collars

A thrust collar manages axial loads within an engine by providing a surface against which other engine components can press, thereby controlling movement along the engine’s axis. This interaction is vital for maintaining the alignment and stability of engine parts under operational stress 1.

Purpose of the 3534109 Thrust Collar

The 3534109 Thrust Collar is designed to manage axial loads in truck engines, ensuring that components remain aligned and operate efficiently. It absorbs and distributes axial forces generated during engine operation, contributing to the overall stability and efficiency of the engine 2.

Key Features

The 3534109 Thrust Collar is constructed from high-quality materials, ensuring durability and resistance to wear. Its design incorporates precise machining for a perfect fit within the engine assembly, and it features a smooth surface finish to minimize friction and wear between moving parts.

Benefits

Utilizing the 3534109 Thrust Collar offers several advantages, including improved engine performance, enhanced durability, and increased reliability. It contributes to smoother engine operation and reduced wear on engine parts, potentially improving fuel economy and reducing emissions.

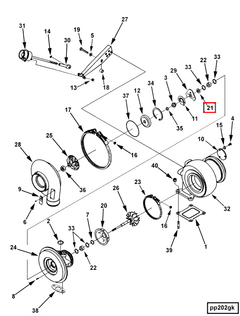

Installation Process

Installing the 3534109 Thrust Collar requires careful attention to detail. The process involves cleaning the installation area, inspecting the thrust collar for damage, and positioning it correctly within the engine assembly. Using appropriate tools and following the manufacturer’s guidelines for torque specifications and alignment is crucial.

Troubleshooting Common Issues

Common issues with thrust collars include misalignment, wear, or damage due to improper installation or operational stress. Troubleshooting involves inspecting the thrust collar and related components for signs of wear or damage, ensuring proper alignment, and verifying installation according to the manufacturer’s specifications.

Maintenance Tips

Regular maintenance of the 3534109 Thrust Collar is vital for its longevity and efficiency. This includes periodic inspection for wear or damage, cleaning the component and its surrounding area, and verifying its alignment within the engine assembly. Adhering to the manufacturer’s recommended maintenance schedule and guidelines is essential.

Role in Engine Performance

The 3534109 Thrust Collar contributes to the overall performance and efficiency of the engine by managing axial loads and maintaining component alignment. Its role in absorbing and distributing forces within the engine helps ensure that components operate within their designed parameters, potentially leading to improved fuel economy and reduced emissions.

Cummins Overview

Cummins Inc. is renowned for its quality and innovation in producing engine components. The company’s reputation is reflected in its wide range of products, including the 3534109 Thrust Collar. Cummins’ commitment to excellence and customer satisfaction underscores its position as a leader in the manufacturing of engine parts.

Thrust Collar 3534109 Compatibility with Cummins Engines

The Thrust Collar part number 3534109 is designed to fit a variety of Cummins engines, ensuring the alignment and stability of the engine’s crankshaft. Below is a detailed overview of the engines with which this thrust collar is compatible:

Compatible Engines

- 6B5.9

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

- ISBE CM2150

- ISBE4 CM850

- ISG12 CM2880 G107

- ISM CM570

- ISM11 CM876 SN

- ISX CM570

- ISX15 CM2250 SN

- ISZ13 CM2150 Z105

- M11 CELECT

- M11 CELECT PLUS

- N14 G

- QSB5.9 CM850

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

- QSC8.3 CM850 (CM2850)

- QSG12/X12 CM2350 G110

- QSK60 CM850 MCRS

- QSM11 CM570

- QSM11 CM876

- QSZ13 CM2150 Z102

Grouping of Compatible Engines

ISBE Series

- ISBE CM2150

- ISBE4 CM850

- ISM CM570

- ISM11 CM876 SN

- ISX CM570

- ISX15 CM2250 SN

- ISZ13 CM2150 Z105

- QSM11 CM570

- QSM11 CM876

QSB Series

- QSB5.9 CM850

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

- QSC8.3 CM850 (CM2850)

- QSK60 CM850 MCRS

- QSZ13 CM2150 Z102

Other Series

- 6B5.9

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

- ISG12 CM2880 G107

- M11 CELECT

- M11 CELECT PLUS

- N14 G

- QSG12/X12 CM2350 G110

This thrust collar is engineered to ensure compatibility across a wide range of Cummins engines, providing a reliable solution for maintaining the integrity of the crankshaft assembly.

Role of Part 3534109 Thrust Collar in Engine Systems

The 3534109 Thrust Collar is a vital component in the efficient operation of various engine systems. It is primarily responsible for managing axial loads within the engine, ensuring smooth and reliable performance.

Integration with Turbocharger Systems

In turbocharger setups, the Thrust Collar works in conjunction with the turbocharger core and aftermarket parts. It maintains the proper alignment and spacing between the turbine housing and the compressor, which is vital for optimal airflow and pressure management.

Function in Aftermarket Turbocharger Assemblies

When dealing with aftermarket turbocharger assemblies, the Thrust Collar ensures that the increased stress and higher operating pressures typical of aftermarket performance parts are adequately managed. This helps in prolonging the lifespan of the turbocharger core and enhancing overall engine reliability.

Role in Heat Exchanger Core Assemblies

In systems involving heat exchanger core assemblies, such as the Assembly Heat Exchanger52W Core and Core Assembly Heat Exchanger55, the Thrust Collar assists in maintaining structural integrity. It helps in distributing axial loads evenly, which is essential for the efficient transfer of heat and maintaining the performance of the heat exchanger.

Interaction with Camshaft and Connecting Rod

The Thrust Collar also interacts with the camshaft and connecting rod in internal combustion engines. By managing axial movement, it ensures that these components operate within their designed parameters, reducing wear and enhancing engine longevity.

Importance in Core Assembly Systems

In core assembly systems, including the Core Assembly Heat Exchanger52 and Core Assembly Heat Exchanger55W, the Thrust Collar ensures that all components remain aligned and operate efficiently. This is essential for maintaining the integrity of the core assembly and ensuring that the engine system performs as intended.

Application in Crosshead and Exhaust Outlet Connection

For engines utilizing a crosshead design, the Thrust Collar helps in managing the axial forces that the crosshead experiences. Similarly, in systems with an exhaust outlet connection, it ensures that the connection remains secure and operates efficiently, contributing to the overall performance and reliability of the engine.

Conclusion

The 3534109 Thrust Collar is a vital component in various engine systems, ensuring that axial loads are managed effectively, components remain aligned, and the engine operates smoothly and reliably.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.