This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3531776 Thrust Collar is a component designed to facilitate the smooth operation of heavy-duty truck engines. Its role is integral to the efficient functioning of the engine, particularly in managing axial loads and ensuring proper alignment of engine components.

Basic Concepts of a Thrust Collar

A thrust collar is a mechanical component that helps in controlling axial movement within an engine. It operates by providing a surface against which other moving parts can press, thereby managing the forces that act along the axis of rotation. In an engine, the thrust collar contributes to maintaining the stability and alignment of rotating components, which is vital for the engine’s performance and longevity 2.

Purpose of the 3531776 Thrust Collar

The 3531776 Thrust Collar is specifically engineered to play a role in the operation of truck engines by managing axial loads. This component helps in maintaining the alignment of the crankshaft and other rotating parts, which is crucial for the engine’s balance and efficiency. By doing so, it contributes to the overall stability and performance of the engine 3.

Key Features

The design of the 3531776 Thrust Collar incorporates specific material characteristics that enhance its performance and durability. It is crafted from materials that offer high resistance to wear and corrosion, ensuring it can withstand the demanding conditions within a truck engine. Its precise engineering allows for optimal contact with other engine components, facilitating smooth operation 1.

Benefits

The use of the 3531776 Thrust Collar in truck engines offers several advantages. It contributes to improved engine efficiency by ensuring that components operate within their designed parameters. Additionally, it reduces wear on connecting components, leading to enhanced overall reliability of the engine. The thrust collar’s role in maintaining component alignment also helps in minimizing vibrations and noise, further contributing to a smoother engine operation 4.

Installation Process

Proper installation of the 3531776 Thrust Collar is vital for its effective function. The process involves ensuring that the engine is clean and free from debris, followed by carefully positioning the thrust collar in its designated location. It is important to follow manufacturer guidelines to ensure that the collar is correctly aligned and secured, which is crucial for the engine’s performance 4.

Common Issues and Troubleshooting

Thrust collars, like any mechanical component, can encounter issues over time. Common problems include wear and misalignment, which can lead to increased engine noise, vibrations, or even component failure. Diagnosing these issues often involves a thorough inspection of the engine’s rotating components. Solutions may range from simple adjustments to replacement of the thrust collar or other affected parts 2.

Maintenance Tips

Routine maintenance is key to ensuring the longevity and optimal performance of the 3531776 Thrust Collar. Regular inspection intervals should be observed to check for signs of wear or damage. Cleaning the collar and its surrounding components can prevent the buildup of debris that might affect its function. Following these maintenance practices can help in identifying potential issues early, allowing for timely interventions 3.

Compatibility and Application

The 3531776 Thrust Collar is designed for use in specific types of engines and truck models. Its application is tailored to meet the demands of these engines, ensuring compatibility and optimal performance. When considering its use, it is important to refer to the manufacturer’s guidelines for compatibility and application notes to ensure it is suitable for the intended engine 4.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted name in the field of engine manufacturing and component production.

Thrust Collar 3531776 Compatibility with Cummins Engines

The Thrust Collar part number 3531776, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part plays a role in maintaining the structural integrity and operational efficiency of the engines by providing necessary support and alignment.

GTA38 G CMEICS G116C

The Thrust Collar 3531776 is specifically engineered to fit the GTA38 G CMEICS G116C engine, ensuring that the engine’s internal components remain properly aligned and reducing wear and tear.

KTA19GC Series

For the KTA19GC engines, the Thrust Collar 3531776 is a component. This part is compatible with both the KTA19GC and the KTA19GC CM558 models, providing support and alignment for the engine’s crankshaft and other moving parts.

KTA38GC Series

Similarly, the Thrust Collar 3531776 is designed to fit the KTA38GC CM558 engine. This ensures that the engine operates smoothly and efficiently by maintaining the correct positioning of the crankshaft.

QSK60 Series

The Thrust Collar 3531776 is also compatible with the QSK60 engines. This includes both the QSK60 CM500 and the QSK60G models. In these engines, the thrust collar helps to stabilize the crankshaft, contributing to the overall performance and longevity of the engine.

QSK78 Series

For the QSK78 CM500 engine, the Thrust Collar 3531776 is a part that ensures the crankshaft remains properly aligned. This helps to maintain the engine’s efficiency and reduce the risk of mechanical failure.

QSM11 CM570

The Thrust Collar 3531776 is also suitable for the QSM11 CM570 engine. This part provides the necessary support and alignment for the engine’s crankshaft, ensuring smooth operation and longevity.

QST30 CM552

Lastly, the Thrust Collar 3531776 fits the QST30 CM552 engine. This ensures that the engine’s internal components remain properly aligned, contributing to the engine’s overall performance and durability.

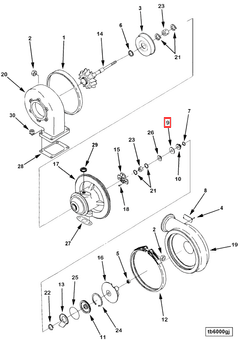

Understanding the Integration of Part 3531776 Thrust Collar in Engine Systems

The Part 3531776 Thrust Collar is a component in the orchestration of various engine systems, ensuring optimal performance and longevity. Its role is particularly significant in the context of aftermarket turbochargers, where it aids in managing the axial loads generated during operation.

In the realm of camshaft mounting, the Thrust Collar works in conjunction with the camshaft to prevent undue movement, thereby maintaining the precision of valve timing which is vital for engine efficiency. This is especially relevant in high-performance engines where even minor deviations can impact overall performance.

When considering the connecting rod assembly, the Thrust Collar helps in stabilizing the rod’s movement, reducing wear and tear on the crankshaft. This stabilization is key in maintaining the integrity of the engine’s power delivery system.

In the Core Assembly Heat Exchanger60 and Core Assembly Heat Exchanger60W, the Thrust Collar ensures that the components remain aligned, facilitating efficient heat transfer. This is critical for maintaining the turbocharger’s operational temperature within safe limits, enhancing its durability and performance.

Similarly, in the Core Heat Exchanger60 Assembly, the Thrust Collar’s role is to keep the assembly components in proper alignment, ensuring that the heat exchanger functions efficiently. This is particularly important in high-stress environments where thermal management is key to engine longevity.

The Cylinder Head integration with the Thrust Collar is another area where its role is significant. By ensuring that the cylinder head remains securely in place, the Thrust Collar contributes to the engine’s sealing efficiency, which is essential for maintaining compression and preventing leaks.

In the context of Heat Exchanger60 Turbocharger systems, the Thrust Collar is instrumental in maintaining the structural integrity of the turbocharger. It helps in managing the axial forces that are a byproduct of the turbocharger’s operation, ensuring that the turbocharger remains efficient and reliable over time.

Lastly, in Turbocharger, Turbocharger Core, and Turbocharger Kit applications, the Thrust Collar is a component. It ensures that the turbocharger’s moving parts are kept in check, allowing for smooth operation and enhancing the turbocharger’s ability to deliver performance without compromising on reliability.

Conclusion

In summary, the Part 3531776 Thrust Collar is a component that, while often overlooked, plays a significant role in the efficient and reliable operation of various engine systems. Its integration into these systems is a testament to its importance in the broader context of engine performance and durability.

-

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ ↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSG12/X12 CM2350 G110. Bulletin Number 4367322.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.