This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

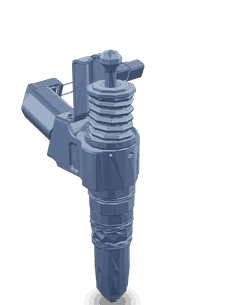

The Cummins 3411760 Injector is a component designed for use in commercial trucks, playing a significant role in the efficient operation of these vehicles. This injector is part of the fuel system, responsible for delivering fuel into the engine’s combustion chambers. Its proper function is vital for the engine’s performance, fuel efficiency, and emissions control.

Basic Concepts of Fuel Injectors

Fuel injectors are devices that deliver pressurized fuel into an engine’s combustion chambers. They operate by atomizing fuel into a fine mist, which mixes with air for combustion. The precise control of fuel delivery by injectors is crucial for efficient combustion, power output, and emissions reduction. In diesel engines, injectors must deliver fuel at high pressures to ensure proper atomization and combustion 1.

Purpose of the Cummins 3411760 Injector

The Cummins 3411760 Injector serves to deliver fuel into the engine’s combustion chambers with precision. It plays a role in the fuel delivery system by ensuring that fuel is injected at the correct time and in the right amount, contributing to combustion efficiency. This injector is designed to work under high pressures, ensuring that fuel is atomized effectively for optimal combustion 2.

Key Features

The Cummins 3411760 Injector is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability. It incorporates advanced technological features that enhance its performance, such as precise fuel delivery mechanisms and resistance to wear and corrosion. These features contribute to its efficiency and longevity in demanding commercial truck applications.

Benefits of Using the Cummins 3411760 Injector

Utilizing the Cummins 3411760 Injector offers several advantages, including improved fuel efficiency, enhanced engine performance, and increased reliability. Its precise fuel delivery contributes to more efficient combustion, leading to better fuel economy. Additionally, the injector’s design and construction support consistent performance under varying operating conditions, contributing to overall engine reliability 3.

Installation and Integration

Installing the Cummins 3411760 Injector into a truck’s engine system requires adherence to specific guidelines to ensure proper function and integration. It is important to follow manufacturer recommendations for installation procedures, including torque specifications and alignment checks, to maintain the injector’s performance and compatibility with the engine system.

Maintenance and Troubleshooting

Maintaining the Cummins 3411760 Injector involves regular inspections and cleaning to prevent buildup and ensure optimal performance. Common issues may include clogged nozzles or leaks, which can be addressed through cleaning or replacement of affected components. Troubleshooting tips include checking for proper fuel pressure and ensuring the injector is securely installed and aligned.

Performance Impact

The Cummins 3411760 Injector affects the overall performance of the truck by contributing to fuel economy, power output, and emissions. Its efficient fuel delivery leads to more complete combustion, which can result in improved fuel efficiency and reduced emissions. Additionally, the injector’s role in the combustion process directly influences the engine’s power output and responsiveness.

Technological Advancements

The Cummins 3411760 Injector incorporates several technological advancements that distinguish it from previous models. These include improved fuel delivery precision, enhanced durability through material innovations, and design features that reduce the risk of wear and corrosion. These advancements contribute to the injector’s superior performance and reliability in commercial truck applications.

Environmental Considerations

Using the Cummins 3411760 Injector contributes to more sustainable trucking operations by reducing emissions. Its precise fuel delivery helps minimize unburned fuel and pollutants, leading to lower emissions output. This aligns with efforts to reduce the environmental impact of commercial transportation and supports more eco-friendly operations.

Cummins Corporation

Cummins Inc. is a leading manufacturer of diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins has established a reputation for producing reliable and efficient automotive components. The company’s commitment to advancing engine technology is evident in its product lineup, including the Cummins 3411760 Injector, which embodies its dedication to performance and sustainability.

Compatibility

The Cummins injector part number 3411760 is compatible with several Cummins engine models, including the N14 CELECT PLUS and QSN14 CM876 N103. These engines are known for their robust design and are widely used in heavy-duty applications, such as trucks, construction equipment, and industrial machinery. The injector is engineered to meet the stringent requirements of these engines, providing reliable and consistent performance.

Role in Engine Systems

The 3411760 Injector is a pivotal component in the orchestration of fuel delivery within engine systems. Its primary function is to atomize fuel into the combustion chamber, ensuring a fine mist that enhances fuel-air mixture efficiency. This atomization is essential for optimal combustion, which directly influences engine performance and emissions.

Conclusion

The Cummins 3411760 Injector is an integral part of the fuel delivery system, working in tandem with the cylinder head, performance parts, and campaign kits to ensure that the engine operates efficiently and effectively. Its role in fuel atomization and delivery is fundamental to the engine’s performance, making it a component of significant importance in the engine system.

-

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩ -

S. A. Miedema, Z. Lu, The Dynamic Behavior of a Diesel Engine, Published by Drir S. A. Miedema, 2010.

↩ -

William B. Ribbens, Understanding Automotive Electronics, Elsevier Science, 2003.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.