This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

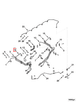

The Cummins Injector Fuel Supply Tube (Part #3282749) is a critical component in heavy-duty truck engines, designed to ensure efficient fuel transport from the fuel tank to the injectors. This part is essential for maintaining engine performance and reliability under demanding conditions.

Basic Concepts of Injector Fuel Supply Tubes

An Injector Fuel Supply Tube is a conduit within a diesel engine’s fuel system that facilitates the transfer of fuel from the fuel tank to the injectors under pressure. This ensures a consistent flow of fuel, contributing to the engine’s efficiency and performance 1.

Purpose and Role in Truck Operation

The Cummins Injector Fuel Supply Tube is engineered to enhance fuel delivery in heavy-duty truck engines. It provides a direct and efficient route for fuel, ensuring the engine receives the precise amount needed for optimal combustion. This contributes to efficient fuel delivery, improved engine performance, and overall reliability 2.

Key Features

The Cummins Injector Fuel Supply Tube is constructed from durable materials to withstand high pressures and temperatures. Its design ensures a secure fit and reliable performance, with features like reinforced sections or specialized coatings to enhance durability and efficiency 3.

Benefits

The use of the Cummins Injector Fuel Supply Tube offers several benefits, including improved fuel efficiency, enhanced engine performance, and reliability in demanding conditions. Its robust construction supports the longevity and performance of the engine 4.

Installation and Compatibility

Proper installation of the Cummins Injector Fuel Supply Tube is crucial for its effective operation. It is designed to be compatible with various Cummins engine models, providing a versatile solution for enhancing fuel delivery in heavy-duty truck applications 5.

Maintenance and Troubleshooting

Routine maintenance of the Cummins Injector Fuel Supply Tube is important for its optimal performance and longevity. This includes regular inspections, cleaning, or replacing the tube as necessary. Troubleshooting common issues may involve checking for proper installation, inspecting connections, and ensuring the tube is free from obstructions 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. The company is committed to delivering high-quality components that enhance the performance and reliability of heavy-duty trucks. Its focus on innovation and quality ensures that products like the Cummins Injector Fuel Supply Tube meet the demanding requirements of modern engines 7.

Compatibility and Installation

The Injector Fuel Supply Tube (3282749) is compatible with several Cummins engine models, including the 6B5.9. Installation involves disconnecting the old tube, preparing the new part, connecting it to the fuel pump and injectors, and testing the system for leaks and smooth operation 8.

Importance and Maintenance Tips

The injector fuel supply tube is vital for the engine’s fuel delivery system. Regular inspections, proper installation, and the use of genuine parts are essential for maintaining engine efficiency and reliability 9.

Role in Engine Systems

The Injector Fuel Supply Tube (part 3282749) is integral to the efficient operation of fuel systems within engine assemblies. It facilitates the precise delivery of fuel from the fuel rail to individual injectors, ensuring optimal combustion and engine performance 10.

Conclusion

The Cummins Injector Fuel Supply Tube (Part #3282749) plays a crucial role in the fuel delivery system of heavy-duty truck engines. Its design, compatibility, and maintenance are essential for ensuring efficient and reliable engine operation.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2670 X122B. Bulletin Number 5504459.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2670 X122B. Bulletin Number 5504459.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2670 X122B. Bulletin Number 5504459.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2670 X122B. Bulletin Number 5504459.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2670 X122B. Bulletin Number 5504459.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for X13 CM2670 X122B. Bulletin Number 5504459.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.