This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

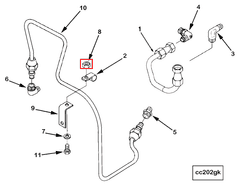

The Compressor Water Outlet Tube, identified by part number 3254450, is a component manufactured by Cummins. This tube is integral to heavy-duty truck systems, facilitating the efficient management of coolant flow to maintain optimal compressor temperature. Cummins, a renowned name in the automotive industry, ensures that this component meets high standards of quality and performance 1.

Function and Operation

The Compressor Water Outlet Tube operates by directing coolant from the compressor to other parts of the cooling system. It plays a role in the system by ensuring that the compressor remains within the desired temperature range, which is vital for its efficient operation and longevity. The tube is designed to handle the pressures and temperatures associated with heavy-duty applications, ensuring consistent coolant flow and temperature regulation 2.

Key Features

The design of the Compressor Water Outlet Tube incorporates several features that enhance its functionality and durability. Constructed from high-quality materials, the tube is resistant to corrosion and capable of withstanding the high pressures and temperatures typical in heavy-duty truck engines. Its design facilitates efficient coolant distribution, ensuring that the compressor and other components receive adequate cooling. The tube is also engineered for seamless integration with other components in the cooling system, promoting overall system efficiency 3.

Benefits

The Compressor Water Outlet Tube offers several advantages. By ensuring optimal compressor temperature, it contributes to enhanced compressor performance and reliability. This, in turn, supports overall engine efficiency, as a well-regulated compressor can operate more effectively. The tube’s durable construction and efficient design also mean that it requires less frequent replacement, offering long-term value to truck operators 4.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for its effective operation. Installation procedures may vary slightly depending on the specific truck model, so it is important to consult the manufacturer’s guidelines for detailed instructions. Ensuring that the tube is correctly aligned and securely fastened will help prevent leaks and ensure optimal coolant flow.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Outlet Tube is relatively straightforward but important for its longevity and effectiveness. Regular inspections for signs of wear, corrosion, or leaks are recommended. If any issues are detected, such as a leak or reduced coolant flow, it may be necessary to replace the tube or address any underlying issues within the cooling system. Keeping the tube and associated components clean and free from debris will also contribute to its efficient operation.

Safety Considerations

When working with the Compressor Water Outlet Tube, it is important to observe several safety protocols. Handling coolant requires caution, as it can be hot and may contain additives that could be harmful if ingested or if they come into contact with skin. Always allow the engine to cool before performing any maintenance tasks, and use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards.

Environmental Impact

The efficient operation of the Compressor Water Outlet Tube contributes to reduced emissions and improved fuel economy. By ensuring that the compressor operates within the optimal temperature range, the tube helps the engine run more efficiently, which can lead to lower fuel consumption and reduced emissions. This aligns with broader efforts to minimize the environmental impact of heavy-duty trucks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. The company’s extensive product range and dedication to quality ensure that components like the Compressor Water Outlet Tube meet the demanding requirements of heavy-duty applications.

Compressor Water Outlet Tube (Part 3254450) in Cummins Engines

The Compressor Water Outlet Tube, identified by part number 3254450, is a critical component in the cooling system of certain Cummins engines. This part is designed to manage the flow of coolant from the compressor section of the engine, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

Application in Specific Cummins Engines

-

M11 CELECT PLUS

- The M11 CELECT PLUS engine utilizes the Compressor Water Outlet Tube to facilitate the transfer of coolant from the turbocharger’s compressor outlet. This part is integral to the engine’s cooling system, helping to prevent overheating and maintain performance.

-

Other Cummins Engines

- While the primary focus is on the M11 CELECT PLUS, the Compressor Water Outlet Tube is also compatible with other Cummins engines that share similar design and cooling system requirements. This ensures that the part can be effectively used across various engine models, providing a standardized solution for coolant management.

Importance in Engine Performance

The Compressor Water Outlet Tube plays a vital role in the engine’s overall cooling strategy. By efficiently channeling coolant away from the compressor, it helps to maintain the integrity of the turbocharger and the engine’s performance. This part is essential for preventing thermal stress and ensuring the longevity of the engine components.

Role of Part 3254450 Compressor Water Outlet Tube in Engine Systems

The part 3254450 Compressor Water Outlet Tube is an integral component in the efficient operation of engine systems, particularly in the management of compressor coolant. This tube facilitates the flow of coolant from the compressor to the plumbing system, ensuring that the compressor remains at an optimal temperature during operation.

In the context of the compressor coolant system, the Compressor Water Outlet Tube directs the coolant away from the compressor after it has absorbed heat. This process is essential for maintaining the compressor’s efficiency and longevity. The coolant, now heated, travels through the tube to the plumbing system where it can be cooled before re-entering the compressor cycle.

The integration of the Compressor Water Outlet Tube with the plumbing system ensures a continuous and regulated flow of coolant. This not only aids in temperature management but also contributes to the overall stability and performance of the engine system. The tube’s design and placement are tailored to accommodate the specific requirements of the engine’s coolant management, enhancing the system’s reliability and effectiveness.

Conclusion

The Compressor Water Outlet Tube, part number 3254450, is a vital component in the cooling systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in managing coolant flow ensures that the compressor operates within optimal temperature ranges, contributing to the engine’s efficiency, reliability, and longevity. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this Cummins part. Additionally, the efficient operation of the Compressor Water Outlet Tube supports broader environmental goals by contributing to reduced emissions and improved fuel economy.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.