This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tur Oil Drain Tube, identified by part number 3254439, is a component manufactured by Cummins, a well-established name in the heavy-duty truck industry. This part is integral to the maintenance regimen of heavy-duty trucks, facilitating efficient oil drainage which is vital for the longevity and performance of the engine.

Function and Operation

The Tur Oil Drain Tube operates as a conduit within the oil drainage system of heavy-duty trucks. It allows for the controlled and efficient removal of oil from the engine, ensuring that the oil can be replaced with fresh lubricant without unnecessary spillage or contamination. The tube is designed to interface with the truck’s oil pan, providing a secure pathway for oil to exit the engine during maintenance procedures 4.

Purpose of the Tur Oil Drain Tube

This Cummins part serves a specific function in the operation and maintenance of heavy-duty trucks. It is responsible for managing oil drainage, which is an important aspect of engine care. By ensuring that old oil is effectively removed from the engine, the tube helps protect the engine from the buildup of contaminants and sludge, which can impair performance and lead to premature wear 3.

Key Features

The Tur Oil Drain Tube is characterized by several key features that enhance its performance. It is constructed from durable materials that can withstand the high temperatures and pressures associated with engine oil. The design of the tube includes precise fittings that ensure a secure connection to the oil pan, minimizing the risk of leaks. Additionally, the tube may incorporate features such as a built-in filter to capture debris during the drainage process, further contributing to engine protection 1.

Benefits

The advantages of using the Tur Oil Drain Tube include improved oil drainage efficiency, which can reduce the time required for maintenance tasks. This efficiency not only saves time but also contributes to enhanced engine longevity by ensuring that the engine is always lubricated with clean oil. The tube’s design also aids in minimizing oil spills, which can be hazardous and difficult to clean 2.

Installation Process

Installing the Tur Oil Drain Tube requires careful attention to detail to ensure proper function and safety. The process involves securing the tube to the oil pan using the provided fittings, ensuring that all connections are tight and free from leaks. It is important to follow the manufacturer’s guidelines during installation to avoid common pitfalls such as improper sealing, which could lead to oil leaks 3.

Troubleshooting Common Issues

Common issues with the Tur Oil Drain Tube may include leaks or blockages. To address these problems, it is important to inspect the tube and its connections regularly. If a leak is detected, the fittings should be re-tightened or replaced if necessary. Blockages can often be resolved by cleaning the tube or, in some cases, replacing it to ensure unobstructed oil flow 3.

Regular Maintenance

To prolong the lifespan of the Tur Oil Drain Tube and ensure consistent performance, it is recommended to conduct routine checks. This includes inspecting the tube for signs of wear or damage, ensuring that all connections remain secure, and cleaning the tube as needed to prevent blockages. Regular maintenance of the tube contributes to the overall reliability of the oil drainage system 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the heavy-duty truck industry. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 4.

Role of Part 3254439 Tur Oil Drain Tube in Engine Systems

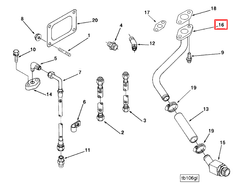

The 3254439 Tur Oil Drain Tube is a component in the efficient operation of various engine systems, particularly those involving the turbocharger and its associated components.

In the Exhaust Manifold system, the Tur Oil Drain Tube facilitates the removal of excess oil that may accumulate during the turbocharger’s operation. This ensures that the manifold operates efficiently without the risk of oil contamination affecting the exhaust flow.

Within the Turbocharger system, the Tur Oil Drain Tube plays a role in maintaining the lubrication system’s integrity. It allows for the safe drainage of oil that has been used to lubricate the turbocharger’s bearings and other moving parts. This prevents oil buildup, which could lead to increased temperatures and potential damage to the turbocharger.

In the context of Turbocharger Plumbing, the Tur Oil Drain Tube is integral to the overall oil management system. It ensures that oil lines remain clear of excess oil, which could otherwise lead to blockages or reduced efficiency in oil circulation.

For the Turbocharger Mounting system, the Tur Oil Drain Tube assists in keeping the turbocharger and its mounting brackets free from oil residue. This contributes to the structural integrity and longevity of the turbocharger assembly by preventing oil-induced corrosion or degradation of materials.

Lastly, in the broader Plumbing system of the engine, the Tur Oil Drain Tube is a component in the maintenance of oil lines and connections. It ensures that all plumbing components remain functional and free from oil contamination, which is essential for the reliable operation of the engine’s lubrication system.

Conclusion

The 3254439 Tur Oil Drain Tube is a vital component in the maintenance of heavy-duty trucks, ensuring efficient oil drainage and contributing to the longevity and performance of the engine. Its design and features are tailored to withstand the demanding conditions of engine operation, providing a secure and efficient means of oil removal. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the reliable operation of the engine’s lubrication system.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ ↩ ↩ ↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.