This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

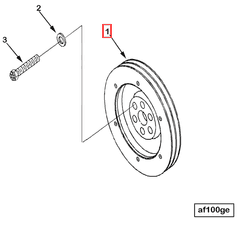

The Cummins 3253405 Crankshaft Pulley is a critical component for commercial trucks, facilitating the transfer of power from the engine to auxiliary systems. Understanding its function and importance is essential for maintaining engine efficiency and reliability.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, or harmonic balancer, is a toothed wheel attached to the front of an engine’s crankshaft. It drives the engine’s accessory belt(s), powering components such as the alternator, water pump, and air conditioning compressor. The pulley converts the rotational motion of the crankshaft into linear motion via the belt, ensuring these systems receive the necessary power to function 1.

Purpose of the 3253405 Crankshaft Pulley

This part ensures the smooth and efficient transfer of power from the engine to its accessory systems. It interacts with the engine’s timing belt or chain, contributing to the synchronization of engine components. The pulley’s design helps reduce vibrations and torsional stresses during engine operation, enhancing overall engine performance and longevity 2.

Key Features

The Cummins 3253405 Crankshaft Pulley is constructed with precision to meet the demanding requirements of commercial truck applications. It is made from durable materials that can withstand high stress and temperatures. The pulley features a specific tooth profile designed to engage securely with the truck’s accessory belts. Its dimensions are tailored to fit Cummins engines precisely, ensuring optimal performance and compatibility.

Benefits

This Cummins part offers several advantages, including improved efficiency in power transfer, enhanced durability under heavy-duty conditions, and increased reliability. Its design contributes to the reduction of engine vibrations, leading to smoother operation. These benefits are particularly valuable in commercial trucks, where engine performance and longevity are essential for operational efficiency 3.

Installation and Compatibility

Proper installation of the 3253405 Crankshaft Pulley is vital for ensuring optimal performance and longevity. It requires precise alignment with the engine’s crankshaft and the accessory belt system. Specific torque settings and alignment procedures should be followed to prevent damage and ensure efficient operation. Compatibility with the engine model is crucial, as it ensures that the pulley fits correctly and functions as intended.

Troubleshooting and Maintenance

Common issues associated with crankshaft pulleys include wear and tear, misalignment, and belt slippage. Regular inspection for signs of damage or wear is recommended to identify potential problems early. Diagnostic procedures may involve checking the pulley’s alignment, inspecting the belt for signs of wear, and ensuring that the pulley is securely fastened to the crankshaft. Maintenance practices, such as regular cleaning and lubrication (where applicable), can help prolong the lifespan of the component.

Performance Enhancements

For those looking to enhance engine performance, modifications to the 3253405 Crankshaft Pulley can be considered. Adjustments to pulley sizing or material upgrades may offer improvements in engine efficiency and power output. However, any modifications should be approached with caution and ideally performed by professionals to ensure compatibility and safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the automotive industry, Cummins is committed to manufacturing high-quality components for commercial vehicles. Their products are known for reliability, efficiency, and durability, making them a preferred choice for commercial truck applications.

Compatibility of 3253405 Crankshaft Pulley

The 3253405 Crankshaft Pulley is designed to fit seamlessly with various Cummins engine models, ensuring optimal performance and reliability. This part is engineered to work with the following Cummins engines:

- N14 CELECT PLUS

When installed in the N14 CELECT PLUS engine, the crankshaft pulley plays a crucial role in the engine’s operation. It is responsible for driving the engine’s ancillary components, such as the alternator, water pump, and air conditioning compressor, by converting the rotational motion of the crankshaft into a usable power source for these systems.

The design and material of the crankshaft pulley are critical for its function. It must withstand the high rotational speeds and stresses encountered in engine operation, ensuring durability and longevity. The precision engineering of part 3253405 guarantees a perfect fit and efficient operation across the specified engine models.

For technicians and fleet managers, understanding the compatibility of the crankshaft pulley with the N14 CELECT PLUS engine is essential for maintenance and repair tasks. Proper installation and regular inspection of this component can prevent unexpected engine failures and ensure the smooth running of the vehicle.

Role of 3253405 Crankshaft Pulley in Engine Systems

The 3253405 Crankshaft Pulley is an integral component in the synchronization and efficient operation of various engine systems. It interfaces directly with the crankshaft, serving as the primary driver for several auxiliary components.

Interaction with the Damper

The Crankshaft Pulley works in conjunction with the damper to mitigate vibrations generated by the engine. As the crankshaft rotates, it produces vibrations that, if left unchecked, could lead to increased wear and reduced efficiency of the engine components. The damper absorbs these vibrations, ensuring smoother operation and prolonging the lifespan of the engine.

Integration with the Vibration Damper Pulley

When combined with a vibration damper pulley, the 3253405 enhances its vibration-dampening capabilities. This setup is particularly beneficial in high-performance engines where the forces and vibrations are significantly greater. The vibration damper pulley helps in maintaining consistent belt tension and reducing the stress on the timing belt or chain.

Connection to the EBM Pulley

In engines equipped with an Electronic Belt Drive Module (EBM) pulley, the Crankshaft Pulley plays a vital role in driving the EBM pulley. This, in turn, controls the operation of various engine accessories such as the alternator, power steering pump, and air conditioning compressor. The precise control offered by the EBM pulley ensures that these accessories operate efficiently under varying engine loads and speeds.

Driving Accessory Pulleys

The Crankshaft Pulley is also responsible for driving other accessory pulleys connected to the engine’s serpentine belt. These pulleys are essential for the operation of components like the water pump, which circulates coolant to prevent engine overheating, and the tensioner pulley, which maintains the correct tension on the serpentine belt to ensure reliable operation of all driven components.

Summary of Component Interaction

In summary, the 3253405 Crankshaft Pulley is a key element in the engine’s drive system. It ensures the smooth and efficient operation of the damper, vibration damper pulley, EBM pulley, and other accessory pulleys. By maintaining consistent belt tension and reducing vibrations, it contributes to the overall reliability and performance of the engine.

Conclusion

The Cummins 3253405 Crankshaft Pulley is a vital component in the operation of commercial truck engines. Its role in transferring power to auxiliary systems, reducing vibrations, and ensuring engine synchronization makes it essential for maintaining engine efficiency and reliability. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are crucial for optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.