This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

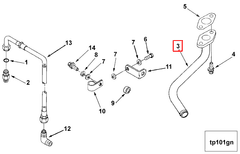

The Tur Oil Drain Tube, identified by part number 3253366 and manufactured by Cummins, is a component integral to the maintenance of heavy-duty trucks. This Cummins part is designed to facilitate the efficient drainage of oil from the engine’s lubrication system, ensuring that the engine operates under optimal conditions. Cummins, a well-established name in the automotive industry, specializes in the production of diesel engines and related components, underscoring the reliability and quality of this part 1.

Function and Operation

The Tur Oil Drain Tube operates as a conduit within the engine’s lubrication system, allowing for the controlled and efficient drainage of oil. This process is vital for maintaining engine health, as it ensures that old or contaminated oil is regularly removed and replaced. The tube’s design facilitates a smooth flow of oil, minimizing the risk of blockages or inefficiencies in the drainage process 2.

Purpose of the Tur Oil Drain Tube

In the context of a heavy-duty truck, the Tur Oil Drain Tube serves a specific role in ensuring the engine’s longevity and performance. By enabling the regular and thorough drainage of oil, it helps in maintaining the engine’s lubrication system in optimal condition. This, in turn, contributes to the overall efficiency and reliability of the truck, reducing the likelihood of engine wear or failure due to inadequate lubrication 3.

Key Features

The Tur Oil Drain Tube is characterized by several key features that enhance its functionality and durability. Its design is tailored to fit seamlessly within the engine’s structure, ensuring a secure and leak-free connection. The materials used in its construction are chosen for their resistance to corrosion and high temperatures, ensuring longevity even under demanding operating conditions. Additionally, the tube may incorporate unique attributes such as reinforced seals or specialized coatings to further enhance its performance and durability 4.

Benefits

The incorporation of the Tur Oil Drain Tube into a truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring that the lubrication system operates under optimal conditions. Furthermore, by facilitating regular and efficient oil drainage, it can reduce the frequency of maintenance intervals, leading to cost savings and increased uptime for the vehicle. The enhanced reliability of the engine, due to consistent and effective oil management, is another significant benefit of this component 5.

Installation and Compatibility

Proper installation of the Tur Oil Drain Tube is crucial for its effective operation. Guidelines for installation should be followed to ensure a secure and leak-free fit within the engine system. Compatibility with various Cummins engine models is an important consideration, and specific requirements for installation may vary depending on the engine type. Adhering to these guidelines and requirements ensures the tube functions as intended, contributing to the overall performance and reliability of the engine 6.

Troubleshooting and Maintenance

Common issues associated with the Tur Oil Drain Tube may include blockages or leaks, which can affect the efficiency of oil drainage. Troubleshooting steps may involve inspecting the tube for signs of wear or damage, ensuring connections are secure, and checking for any obstructions within the tube. Regular maintenance, such as cleaning and inspecting the tube during routine engine servicing, can help ensure its longevity and efficient operation 7.

Safety Considerations

When working with the Tur Oil Drain Tube, it is important to observe certain safety practices. Handling hot oil requires caution to avoid burns, and ensuring the tube is properly sealed is crucial to prevent leaks, which can pose a fire hazard. Additionally, following manufacturer guidelines for installation and maintenance can help mitigate risks associated with improper use or installation of the component 8.

Environmental Impact

The use and disposal of the Tur Oil Drain Tube, like any automotive component, have environmental considerations. Proper disposal of used oil and recycling of the tube, where possible, are important practices to minimize environmental impact. Cummins and other manufacturers often provide guidelines for the responsible disposal and recycling of their products, contributing to sustainable practices in the automotive industry 9.

Cummins Corporation

Cummins Corporation, the manufacturer of the Tur Oil Drain Tube, has a long-standing history in the automotive industry, particularly in the production of diesel engines and components. Founded with a commitment to innovation and quality, Cummins has grown to become a global leader in engine technology, providing reliable and efficient solutions for a wide range of applications. Their expertise in engine design and manufacturing underscores the quality and reliability of components like the Tur Oil Drain Tube 10.

Role of Part 3253366 in Engine Systems

The Tur Oil Drain Tube, identified by part number 3253366, is an integral component in the efficient operation of various engine systems, particularly in the context of the Engine Bay Module (EBM). This tube is essential for the proper functioning of the plumbing, turbo, turbocharger mounting, and turbocharger plumbing systems.

Plumbing System

In the plumbing system, the Tur Oil Drain Tube facilitates the controlled and efficient drainage of oil. This is vital for maintaining the cleanliness and integrity of the oil, ensuring it remains free from contaminants that could otherwise degrade engine performance. The tube allows for the periodic removal of oil, which helps in preventing the buildup of sludge and other impurities within the system.

Turbo System

For the turbo system, the Tur Oil Drain Tube plays a significant role in maintaining the turbo’s lubrication. Proper lubrication is essential for the turbo’s bearings and other moving parts, ensuring they operate smoothly and efficiently. The tube allows for the drainage of excess oil, which prevents over-lubrication that could lead to inefficiencies or even damage to the turbo.

Turbocharger Mounting

In the context of turbocharger mounting, the Tur Oil Drain Tube ensures that the area around the turbocharger remains free from oil leaks. This is important for the structural integrity of the mounting system, as oil leaks can lead to corrosion and weakening of the mounting components. By providing a reliable drainage path, the tube helps in preserving the turbocharger’s mounting system.

Turbocharger Plumbing

Finally, within the turbocharger plumbing system, the Tur Oil Drain Tube is instrumental in managing the flow of oil to and from the turbocharger. It ensures that the oil supply lines remain clear of excess oil, which could otherwise impede the flow and lead to pressure issues. This contributes to the overall efficiency and reliability of the turbocharger plumbing system.

Conclusion

In summary, the Tur Oil Drain Tube (part 3253366) is a key component that enhances the functionality and reliability of the plumbing, turbo, turbocharger mounting, and turbocharger plumbing systems within the engine bay module. Its role in facilitating efficient oil drainage is crucial for maintaining engine health, ensuring optimal performance, and contributing to the overall efficiency and reliability of heavy-duty trucks.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Cummins Corporation. Fault Code Troubleshooting Manual. Bulletin Number 4358468.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Cummins Corporation. Fault Code Troubleshooting Manual. Bulletin Number 4358468.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.