This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tur Oil Drain Tube, identified by part number 3251193 and manufactured by Cummins, is a critical component in the maintenance of heavy-duty trucks. This part is essential for the efficient drainage of oil during maintenance procedures, ensuring the engine remains well-lubricated and performs optimally 1.

Function and Operation

The Tur Oil Drain Tube serves as a conduit within the engine’s lubrication system, allowing for the controlled release of oil during oil changes. This process is vital for maintaining engine health by removing contaminants and degraded oil that can impair performance over time 2. The tube’s design ensures a secure fit within the engine’s oil pan and features a smooth interior to minimize resistance during drainage, facilitating a quicker and more complete oil change.

Key Features

Constructed from durable materials, the Tur Oil Drain Tube is designed to withstand the harsh conditions within an engine environment. Its precision-engineered dimensions and threading are tailored to fit specific Cummins engine models, ensuring a perfect seal and preventing leaks. The tube’s robust connection mechanism and smooth interior surface enhance both durability and efficiency during oil changes.

Benefits of Using the Tur Oil Drain Tube

Utilizing the Tur Oil Drain Tube offers several advantages, including improved engine performance through consistent lubrication with clean oil, which can extend the engine’s operational life by reducing wear on moving parts 3. The tube’s design simplifies the oil change process, making maintenance more efficient and less time-consuming for fleet managers and technicians.

Installation and Compatibility

Proper installation of the Tur Oil Drain Tube is crucial for ensuring a secure and leak-free connection. Compatibility with various Cummins engine models is a key consideration, and specific requirements or considerations for installation may vary depending on the engine model. It is advisable to consult the manufacturer’s documentation for detailed instructions and compatibility information.

Maintenance and Troubleshooting

Regular maintenance of the Tur Oil Drain Tube is recommended to ensure optimal performance. This includes inspecting the tube for signs of wear or damage during routine oil changes. Common issues such as leaks or blockages can often be addressed through cleaning or, in more severe cases, replacement. Promptly addressing any issues can help maintain the efficiency of the engine’s lubrication system.

Safety Considerations

When working with the Tur Oil Drain Tube, it is important to observe safety practices to protect both the individual and the environment. This includes handling hot oil with care to avoid burns, ensuring the proper disposal of used oil to prevent environmental contamination, and securing the tube during installation to prevent leaks, which could lead to hazardous conditions.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its extensive product range, which includes components designed to enhance the performance, efficiency, and reliability of engines across various applications.

Role of Part 3251193 Tur Oil Drain Tube in Engine Systems

The Tur Oil Drain Tube is an essential component in the efficient operation of engine systems, particularly in those equipped with turbochargers. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that the turbocharger operates within optimal parameters.

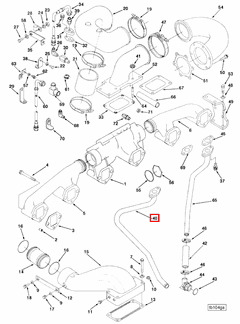

Integration with Turbocharger Mounting

When the turbocharger is mounted onto the engine, the Tur Oil Drain Tube is strategically positioned to connect the turbocharger’s oil supply and return lines. This connection is vital for maintaining a consistent flow of oil to the turbocharger bearings and other moving parts. The drain tube ensures that any excess oil, which may accumulate due to changes in engine RPM or temperature variations, is efficiently returned to the engine’s oil sump. This process helps in preventing oil starvation and ensures that the turbocharger remains well-lubricated under all operating conditions.

Interaction with Lubrication System

The Tur Oil Drain Tube interacts seamlessly with the engine’s lubrication system. It is designed to work in conjunction with the oil pump, filter, and various oil passages within the engine block. By providing a dedicated pathway for oil drainage, the tube helps maintain the correct oil level and pressure within the turbocharger. This is particularly important during high-performance scenarios where the turbocharger is under significant stress.

Contribution to Engine Performance and Longevity

Efficient oil drainage facilitated by the Tur Oil Drain Tube contributes to the overall performance and longevity of the engine. By ensuring that the turbocharger is properly lubricated, the tube helps reduce friction and wear on critical components. This, in turn, leads to smoother operation, enhanced reliability, and potentially extended service intervals for the turbocharger and associated engine parts.

Conclusion

In summary, the Tur Oil Drain Tube (part number 3251193) plays a significant role in the effective functioning of engine systems, particularly those with turbochargers. Its integration with turbocharger mounting and the lubrication system ensures optimal performance and durability of the engine components. Regular maintenance and proper installation are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.