This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3201707 Tube Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining the truck’s performance and longevity.

Basic Concepts of Tube Connectors

Tube connectors are devices used to join tubes in fluid systems, allowing for the transfer of liquids or gases between different parts of the system 1. In the context of heavy-duty trucks, these connectors play a role in ensuring that fluids such as fuel, coolant, and hydraulic fluid are transported efficiently and without leakage. They are designed to withstand the pressures and temperatures associated with these systems, ensuring a secure and durable connection 2.

Purpose of the 3201707 Tube Connector

The Cummins 3201707 Tube Connector is specifically designed to connect tubes within a truck’s fluid system. Its function is to facilitate the flow of fluids between components, ensuring that the system operates smoothly. By providing a reliable connection point, it helps maintain the integrity of the fluid pathways, which is important for the truck’s performance 3.

Key Features

The 3201707 Tube Connector features a design that includes a robust material composition, typically involving metals that offer high resistance to corrosion and wear. Its design elements may include threaded connections or clamps that ensure a tight seal. Unique attributes such as reinforced joints or specialized coatings may enhance its performance and durability, making it suitable for the demanding conditions encountered in commercial trucking 4.

Benefits

The advantages of using the 3201707 Tube Connector include improved efficiency in fluid transfer, increased durability, and enhanced reliability under harsh operating conditions. Its design contributes to minimizing leaks and maintaining system pressure, which are important for the truck’s operational efficiency and safety 5.

Installation Process

Installing the 3201707 Tube Connector involves several steps to ensure a secure and effective connection. The process may require specific tools, such as wrenches or torque wrenches, to achieve the correct tightness. Best practices include cleaning the connection points before installation, applying any necessary sealants, and following the manufacturer’s torque specifications to prevent over-tightening or under-tightening 6.

Troubleshooting Common Issues

Common problems with tube connectors, such as leaks or corrosion, can often be addressed through routine inspections and maintenance. Troubleshooting steps may involve checking for proper torque on connections, inspecting for signs of wear or damage, and cleaning or replacing connectors as needed to maintain system integrity 7.

Maintenance Tips

Regular maintenance practices can help prolong the life of the 3201707 Tube Connector. This includes routine inspections for signs of wear, corrosion, or leaks, and cleaning the connector and surrounding areas to prevent buildup that could affect performance. Following these practices can contribute to the connector’s longevity and the truck’s overall reliability 8.

Compatibility and Usage

The 3201707 Tube Connector is designed for use in specific applications within various truck systems. It is important to consider compatibility with other components to ensure proper function and integration within the system. Understanding its typical applications and any compatibility considerations can help in selecting the appropriate connector for a given system 9.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles 10.

Compatibility with Cummins Engines

The Tube Connector 3201707, manufactured by Cummins, is designed to ensure efficient coolant flow, maintaining optimal engine temperature and performance. It is compatible with a range of Cummins engines, including the K19, K38, and K50 series.

K19 and K38 Engines

For the K19 and K38 engines, the Tube Connector 3201707 plays a role in the engine’s cooling circuit. These engines, known for their robust construction and reliability, benefit from the precise fit and durability of this connector. The part’s design ensures a secure connection between the coolant tubes, preventing leaks and maintaining system integrity 11.

K50 Engine

The K50 engine, part of Cummins’ lineup, also integrates the Tube Connector 3201707 seamlessly. This engine, designed for high-performance applications, relies on the connector’s ability to withstand high pressures and temperatures. The connector’s compatibility with the K50 engine ensures that the cooling system operates efficiently, contributing to the engine’s overall longevity and performance 12.

Grouping of Engines

The Tube Connector 3201707 is particularly suited for the K19, K38, and K50 engines due to their shared design principles and engineering requirements. These engines, while differing in specific applications and capacities, share a common need for reliable and efficient cooling system components. The connector’s design accommodates these shared needs, providing a consistent and effective solution across the engine series 13.

Role of the 3201707 Tube Connector in Engine Systems

The 3201707 Tube Connector is a component that facilitates the secure and efficient connection of various engine system components. It plays a role in ensuring the smooth operation and integration of several key parts within the engine assembly.

Integration with Engine Wiring and Harness

The Tube Connector is instrumental in linking the engine wiring and harness to other components. It provides a reliable connection point that ensures electrical signals and power are transmitted without interruption. This is particularly important for maintaining the functionality of sensors, actuators, and other electronic components that are vital for engine performance and diagnostics 14.

Connection to Exhaust Outlet and Exhaust Outlet Connection

In exhaust systems, the Tube Connector is used to join the exhaust outlet to the exhaust outlet connection. This connection is vital for directing exhaust gases away from the engine efficiently. It helps in maintaining the integrity of the exhaust flow, which is essential for reducing emissions and enhancing engine performance 15.

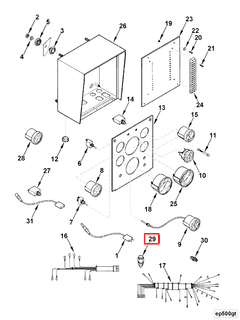

Role in Instrument Panel and Instrument Panel Mounting

The Tube Connector also plays a part in the instrumentation system of the engine. It connects various sensors and gauges to the instrument panel, ensuring that data such as engine temperature, oil pressure, and other vital metrics are accurately transmitted to the driver. This connection is crucial for the monitoring and maintenance of engine health 16.

Interaction with Belt Guard

In systems where a belt guard is used to protect moving parts, the Tube Connector may be employed to secure wiring and hoses that run alongside or through the guard. This ensures that these components remain protected and do not interfere with the operation of the belt or other rotating parts 17.

Ensuring Secure and Efficient Connections

Overall, the 3201707 Tube Connector is designed to provide secure and efficient connections across various engine components. Its role in linking critical systems such as wiring, exhaust, and instrumentation underscores its importance in the overall functionality and reliability of the engine 18.

Conclusion

The Cummins 3201707 Tube Connector is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable fluid transfer. Its robust design, compatibility with various Cummins engines, and role in critical engine systems highlight its importance in maintaining vehicle performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Cummins Inc. (n.d.). QSK19 CM2150 Electronic Control System. Troubleshooting and Repair Manual, Bulletin Number 4022094.

↩ -

Aird, F. (2001).

↩ -

Sobey, E. (2009).

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019).

↩ -

Cummins Inc. (n.d.).

↩ -

Aird, F. (2001).

↩ -

Sobey, E. (2009).

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019).

↩ -

Cummins Inc. (n.d.).

↩ -

Aird, F. (2001).

↩ -

Sobey, E. (2009).

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019).

↩ -

Cummins Inc. (n.d.).

↩ -

Aird, F. (2001).

↩ -

Sobey, E. (2009).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.