This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

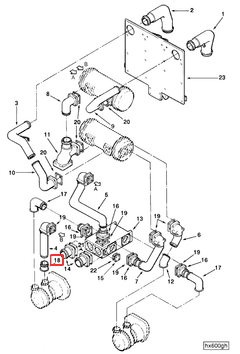

The Seawater Connection 3200883 is a component designed by Cummins for use in heavy-duty trucks. This part is integral to the operation of the truck’s cooling system, ensuring that the engine maintains optimal temperature levels during operation. Its role is significant in enhancing the efficiency and reliability of the truck’s engine, particularly in demanding operational environments.

Basic Concepts of Seawater Connections

Seawater connections are components used in the cooling systems of heavy-duty trucks, especially those operating in marine or coastal environments. These connections facilitate the intake of seawater, which is then used to cool the engine. The process involves circulating seawater through the engine’s cooling system, where it absorbs heat and is subsequently expelled. This mechanism is vital for maintaining engine temperature, preventing overheating, and ensuring consistent performance 1.

Purpose of the Seawater Connection 3200883

The Seawater Connection 3200883 plays a role in the cooling system by providing a secure and efficient pathway for seawater to enter the system. It ensures that the cooling process is uninterrupted and effective, which is crucial for engine performance. By maintaining optimal engine temperature, this component helps in preserving engine efficiency and longevity.

Key Features

The Seawater Connection 3200883 is characterized by several key features that enhance its functionality. It is constructed from durable materials that resist corrosion, ensuring longevity even in harsh marine environments. The design includes precise fittings and seals to prevent leaks, ensuring that the cooling system operates efficiently. Additionally, the component is engineered to withstand high pressure and temperature variations, making it suitable for demanding applications.

Benefits

The advantages of using the Seawater Connection 3200883 include improved engine cooling efficiency, which leads to better overall engine performance. Its durable construction ensures reliability under various operating conditions, reducing the need for frequent replacements. The component’s design also contributes to the ease of maintenance, allowing for straightforward inspection and servicing.

Installation Process

Installing the Seawater Connection 3200883 involves several steps to ensure proper integration into the truck’s cooling system. Begin by ensuring the engine is cool and the system is depressurized. Use the appropriate tools to remove the old connection, if applicable. Clean the installation area to remove any debris or old sealant. Apply a compatible sealant to the threads of the new connection. Carefully thread the Seawater Connection 3200883 into place, ensuring it is snug but not overtightened to avoid damage. Finally, test the connection for leaks by running the engine and monitoring the cooling system.

Maintenance Tips

To ensure the optimal performance and longevity of the Seawater Connection 3200883, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the connection and surrounding areas can prevent the buildup of debris that might impede its function. If any damage is detected, prompt replacement is advised to maintain the integrity of the cooling system.

Troubleshooting Common Issues

Common issues with the Seawater Connection 3200883 may include leaks or corrosion. Leaks can often be addressed by re-sealing the connection or replacing damaged gaskets. Corrosion may require more extensive cleaning or, in severe cases, replacement of the component. Regular maintenance can help identify and mitigate these issues before they lead to significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovative solutions and commitment to quality. The company’s product range includes engines and components for various applications, including heavy-duty trucks, where reliability and performance are paramount. Cummins’ reputation in the automotive industry is built on its dedication to excellence and customer satisfaction.

Seawater Connection Part 3200883 in Cummins Engines

The Seawater Connection part 3200883 is a critical component in the cooling systems of various Cummins marine engines. This part is designed to facilitate the flow of seawater into the engine’s cooling system, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

K19 and K38 Engines

For the K19 and K38 engines, the Seawater Connection part 3200883 is integral to the engine’s cooling mechanism. These engines are typically used in smaller to medium-sized marine applications where reliable and efficient cooling is paramount. The part interfaces directly with the engine’s seawater intake system, providing a secure and leak-proof connection that withstands the harsh marine environment.

K50 Engine

The K50 engine, which is part of Cummins’ higher-power marine engine lineup, also utilizes the Seawater Connection part 3200883. This engine is designed for larger marine vessels and requires robust cooling solutions to handle higher power outputs. The part ensures that seawater is efficiently channeled into the engine’s cooling system, supporting the engine’s performance and longevity under demanding conditions.

Grouping Considerations

While the K19 and K38 engines share similarities in their cooling system requirements, the K50 engine’s higher power demands necessitate a more robust and reliable connection. The Seawater Connection part 3200883 is engineered to meet these varying needs, ensuring compatibility and performance across different engine models.

Role of Part 3200883 Seawater Connection in Engine Systems

The part 3200883 Seawater Connection is integral to the efficient operation of various engine components by facilitating the flow of seawater, which is essential for cooling and lubrication purposes.

Integration with the Drive and Fan

In engine systems, the drive mechanism often relies on a cooling system to maintain optimal operating temperatures. The seawater connection ensures a consistent supply of cool seawater to the drive, preventing overheating and ensuring smooth operation. Similarly, the fan, which aids in dissipating heat from the engine, benefits from the cool seawater supplied through the connection, enhancing its efficiency.

Functionality in Kit 2-Sea Water Pump and Raw Water Pump

The Kit 2-Sea Water Pump and the Raw Water Pump are designed to circulate seawater through the engine’s cooling passages. The seawater connection plays a pivotal role here by providing a secure and reliable pathway for the seawater to enter the pump system. This ensures that the pumps can effectively draw in and circulate seawater, maintaining the engine’s temperature within safe limits.

Interaction with Raw Water System

In systems where raw water is used for cooling, the seawater connection is the initial point of entry for the raw water into the engine’s cooling circuit. It ensures that the raw water, which may include a mix of seawater and freshwater, is efficiently channeled to the various cooling components, thereby supporting the overall cooling efficiency of the engine.

By seamlessly integrating with these components, the part 3200883 Seawater Connection contributes to the reliable and efficient operation of the engine system, ensuring that all cooling-related functions are performed effectively.

Conclusion

The Seawater Connection 3200883 by Cummins is a vital component in the cooling systems of heavy-duty trucks and marine engines. Its durable construction, precise design, and efficient functionality ensure optimal engine performance and longevity. Regular maintenance and prompt troubleshooting of common issues are essential to maximize the benefits of this component.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.