This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sea Water Connection 3200882 is a specialized component designed by Cummins for use in heavy-duty trucks. Its primary function is to facilitate the connection between the engine’s cooling system and a seawater source, typically used in marine or industrial applications where freshwater is scarce. This component plays a role in the engine cooling system by allowing the use of seawater as a coolant, which helps maintain optimal engine temperature under demanding operational conditions 1.

Basic Concepts of Sea Water Connection

Sea water connections are integral to cooling systems in environments where freshwater is limited. These connections enable the use of seawater, which is abundant in marine and some industrial settings, as a coolant. The fundamental principle behind sea water connections involves circulating seawater through the engine’s cooling passages to absorb heat, which is then dissipated back into the environment. This process is vital for maintaining engine temperature within safe operating limits, preventing overheating, and ensuring efficient engine performance 2.

Purpose of Sea Water Connection 3200882

The Sea Water Connection 3200882 is specifically designed to integrate seamlessly with the engine cooling system of heavy-duty trucks. It allows for the direct connection of seawater to the cooling system, enabling the use of seawater as a coolant. This component ensures that the engine remains at an optimal temperature, even in harsh operating conditions where traditional freshwater cooling may not be feasible. Its role is crucial in environments where seawater is the primary available coolant source 3.

Key Features

The Sea Water Connection 3200882 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and wear, ensuring longevity in harsh marine environments. The design includes precise fittings and seals to prevent leaks and maintain a secure connection. Additionally, it features easy-to-use connectors that simplify installation and maintenance, making it a reliable choice for heavy-duty applications.

Benefits

The advantages of using the Sea Water Connection 3200882 include improved cooling efficiency, enhanced reliability, and increased longevity compared to alternative components. Its design allows for efficient heat dissipation, ensuring the engine operates within optimal temperature ranges. The robust construction and corrosion-resistant materials contribute to its durability, reducing the need for frequent replacements. Moreover, its compatibility with heavy-duty truck engines makes it a versatile solution for various applications.

Installation Process

Installing the Sea Water Connection 3200882 requires careful attention to detail to ensure optimal performance and safety. Begin by ensuring the engine is cool and the cooling system is drained. Locate the appropriate connection points on the engine and align the Sea Water Connection 3200882 with these points. Secure the connections using the provided fittings and seals, ensuring a tight and leak-free fit. Finally, refill the cooling system with seawater and check for any leaks before starting the engine. Following these steps will help ensure the component functions correctly and efficiently.

Common Issues and Troubleshooting

Typical problems associated with sea water connections include leaks, corrosion, and blockages. To address these issues, regularly inspect the connections for signs of wear or damage. If leaks are detected, tighten the fittings or replace any worn seals. Corrosion can be mitigated by using high-quality, corrosion-resistant materials and regularly cleaning the connections. Blockages may occur due to debris in the seawater; therefore, it is important to use filters in the cooling system to prevent such issues. Promptly addressing these problems will help maintain the efficiency and reliability of the cooling system.

Maintenance Tips

To prolong the lifespan of the Sea Water Connection 3200882 and ensure consistent performance, adhere to routine maintenance practices. Inspect the connections regularly for signs of wear, corrosion, or leaks. Clean the fittings and seals to remove any buildup of minerals or debris from the seawater. Additionally, ensure that the cooling system is properly flushed and maintained to prevent blockages and ensure efficient heat dissipation. Following these maintenance tips will help maintain the component’s performance and durability.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has consistently delivered high-quality components and engines known for their reliability and performance. The company is committed to innovation and excellence, providing solutions that meet the demanding needs of various applications. Cummins’ dedication to producing durable and efficient components is evident in their Sea Water Connection 3200882, designed to enhance the cooling systems of heavy-duty trucks.

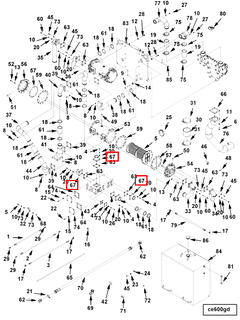

Sea Water Connection Part 3200882 in Cummins Engines

The Sea Water Connection part 3200882 is a crucial component in the cooling systems of various Cummins marine engines. This part is integral to the operation of engines such as the K19, K38, and K50 series.

K19 Series

In the K19 series, the Sea Water Connection part 3200882 is designed to facilitate the flow of seawater into the engine’s cooling system. This ensures that the engine maintains optimal operating temperatures, which is essential for performance and longevity. The part is engineered to withstand the harsh marine environment, providing a reliable connection that minimizes the risk of leaks.

K38 Series

Similarly, in the K38 series, the Sea Water Connection part 3200882 plays a pivotal role in the engine’s cooling mechanism. The design of this part ensures efficient seawater flow, which is critical for the cooling process. The robust construction of the part guarantees durability and reliability, even under the demanding conditions of marine operations.

K50 Series

For the K50 series, the Sea Water Connection part 3200882 is equally important. This part is engineered to provide a seamless connection for seawater intake, ensuring that the engine’s cooling system functions effectively. The design and materials used in this part are chosen to provide long-lasting performance and to resist the corrosive effects of seawater.

Grouping of Engines

The K19, K38, and K50 series engines share a common requirement for efficient and reliable seawater connections. The part 3200882 is designed to meet these needs, ensuring that each engine in these series can operate efficiently and reliably. The commonality in design allows for easier maintenance and repair, as the same part can be used across different engine models within these series.

Role of Part 3200882 Sea Water Connection in Engine Systems

The Part 3200882 Sea Water Connection is an essential component in the efficient operation of various engine systems, particularly those involving heat exchangers and auxiliary cooling mechanisms.

In systems equipped with heat exchangers, the Sea Water Connection facilitates the flow of sea water, which acts as a coolant. This connection is integral to the heat exchanger’s function, allowing it to transfer heat from the engine’s raw water system to the surrounding sea water, thereby maintaining optimal engine temperatures.

When integrated with auxiliary cooling systems, the Sea Water Connection ensures a consistent supply of cool sea water, enhancing the efficiency of the cooling process. This is particularly important in high-performance engines where maintaining precise temperature control is necessary for peak performance and longevity.

In plumbing systems associated with heat exchangers, the Sea Water Connection plays a pivotal role. It ensures a secure and leak-free passage for sea water, which is vital for the overall integrity and efficiency of the plumbing network.

For systems utilizing a pump in conjunction with a heat exchanger, the Sea Water Connection is the link that allows the pump to draw in sea water efficiently. This setup is fundamental in systems where the pump is responsible for circulating sea water through the heat exchanger, aiding in the dissipation of heat from the engine.

In summary, the Part 3200882 Sea Water Connection is a key component in various engine systems, ensuring the effective transfer and circulation of sea water for cooling purposes. Its proper integration and maintenance are essential for the reliable operation of heat exchangers, auxiliary cooling systems, and associated plumbing and pumping mechanisms.

Conclusion

The Sea Water Connection 3200882 by Cummins is a vital component for heavy-duty truck engines, particularly in marine and industrial applications where seawater is used as a coolant. Its design, featuring high-quality, corrosion-resistant materials and precise fittings, ensures efficient heat dissipation and reliable operation under harsh conditions. Regular maintenance and proper installation are crucial for maximizing the performance and longevity of this component. Cummins’ commitment to innovation and excellence is reflected in the Sea Water Connection 3200882, making it a dependable solution for engine cooling systems.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics, Creative Commons, 2024.

↩ -

Steve Rendle and Martynn Randall, Haynes Diesel Engine Systems and Data Book, Haynes Publishing, 2000.

↩ -

Richard Stone, Introduction to Internal Combustion Engines, Fourth Edition, Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.