This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

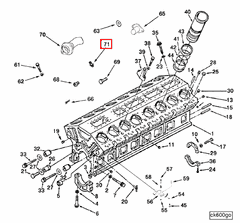

The 3178534 Reducing Hexagon Nipple, manufactured by Cummins, is a specialized component used in commercial trucks. Cummins is renowned in the automotive industry for its high-quality engine and component manufacturing. This particular nipple is integral to the fluid transfer systems in trucks, ensuring efficient and reliable operation.

Basic Concepts

A Reducing Hexagon Nipple is a type of fitting used in fluid systems to connect pipes or hoses of different diameters. It features a hexagonal shape, which allows for easy tightening and loosening using a wrench. In the context of a truck’s components, this fitting facilitates the transfer of fluids between systems with varying pipe sizes 1.

Purpose and Function

The 3178534 is designed to connect different sections of a truck’s fluid transfer system. It is typically positioned at junctions where pipes of different diameters meet. This fitting ensures a secure and leak-free connection, allowing for the smooth transfer of fluids such as fuel, coolant, or hydraulic fluid. Its role is vital in maintaining the integrity and efficiency of the fluid transfer process within the truck 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to corrosion. It features precise thread specifications that guarantee a tight and secure fit. The hexagonal shape of the nipple allows for easy manipulation with standard tools, enhancing both installation and maintenance processes. Additionally, the design includes features that enhance its performance under various operating conditions 3.

Benefits

Using the 3178534 offers several advantages. It provides efficient fluid transfer due to its secure fitting design, which minimizes the risk of leaks. The ease of installation is another benefit, as the hexagonal shape allows for straightforward tightening and loosening. Furthermore, its compatibility with a wide range of truck components ensures versatile application across different models and systems 4.

Installation and Usage

Proper installation of the 3178534 involves several steps to ensure a secure fit. Begin by cleaning the connection points to remove any debris or contaminants. Apply a compatible thread sealant to the threads of the nipple to enhance the seal. Use a wrench to tighten the nipple onto the pipe or hose, ensuring it is snug but not overtightened to avoid damage. Verify the connection by checking for leaks after the system is pressurized.

Maintenance and Troubleshooting

Regular maintenance of the 3178534 is important to prolong its lifespan and ensure continued efficient operation. Inspect the fitting periodically for signs of wear, corrosion, or leaks. If any issues are detected, address them promptly by either tightening the connection or replacing the nipple if necessary. Common problems may include leaks due to improper installation or wear over time, which can often be resolved with proper maintenance practices.

Safety Considerations

When working with the 3178534, it is important to observe several safety practices. Ensure that the system is depressurized before beginning any installation or maintenance work to avoid injury from pressurized fluid. Use the appropriate tools and follow manufacturer guidelines to prevent damage to the fitting or surrounding components. Additionally, wear protective gear, such as gloves and safety glasses, to protect against potential hazards during handling and installation.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is known for its commitment to quality, innovation, and reliability in engine and component manufacturing. Cummins’ history of producing high-performance parts, including the 3178534, underscores their dedication to enhancing the efficiency and durability of commercial trucks. Their products are designed with precision and tested under rigorous conditions to ensure they meet the demanding requirements of the industry.

Cummins Part 3178534: Reducing Hexagon Nipple in Engine Applications

The Cummins part 3178534, a Reducing Hexagon Nipple, is a crucial component in the engine systems of various Cummins engines. This part is designed to facilitate the connection between different sections of the engine’s fuel or fluid lines, ensuring a secure and leak-free interface. Its hexagonal shape allows for easy handling and tightening, which is essential for maintaining the integrity of the engine’s fluid systems.

Application in Cummins Engines

K50 Series

In the K50 series engines, the Reducing Hexagon Nipple (part 3178534) is integral to the engine’s fuel delivery system. This part is typically used to connect the high-pressure fuel lines to the injectors or other critical components. The precise fit and robust design of the nipple ensure that the engine operates efficiently and reliably, minimizing the risk of fuel leaks and maintaining optimal pressure levels.

Group Applications

The part 3178534 is also utilized in various engine groups where a reduction in line size is necessary. This could be for applications requiring a transition from larger to smaller diameter lines, ensuring that the flow characteristics are maintained without compromising the system’s performance. The hexagon nipple’s design allows for a secure and tight connection, which is vital in high-pressure environments typical of engine systems.

The use of the Reducing Hexagon Nipple in these engines underscores Cummins’ commitment to providing high-quality, durable components that enhance engine performance and longevity.

Role of Part 3178534 Reducing Hexagon Nipple in Engine Systems

The 3178534 Reducing Hexagon Nipple is an essential component in various engine systems, facilitating the efficient transfer of fluids and gases between different sections of the engine. This component is particularly significant in the following assemblies and parts:

-

Short Block K50G3 Assembly: In this assembly, the Reducing Hexagon Nipple ensures a secure and leak-free connection between the cylinder block and other engine components, aiding in the smooth operation of the engine.

-

Base Part and Base Parts: When integrated into base parts, this nipple plays a role in maintaining the integrity of fluid pathways, which is vital for the engine’s lubrication and cooling systems.

-

Cylinder and Cylinder Block: Within the cylinder block, the Reducing Hexagon Nipple helps in the precise distribution of coolant or oil, enhancing the engine’s thermal management and overall performance.

-

Long Block Assembly - 50: In this comprehensive assembly, the nipple contributes to the efficient flow of essential fluids, supporting the engine’s durability and reliability.

-

Short Block Assembly - 50 and Short Block Assy - K50: These assemblies benefit from the nipple’s ability to provide a consistent and secure connection, which is fundamental for the engine’s operational stability.

-

Step White Smoke Kit: In diagnostic kits like the Step White Smoke Kit, the Reducing Hexagon Nipple is used to simulate or test fluid flow scenarios, assisting in the identification and resolution of engine issues.

Overall, the Reducing Hexagon Nipple is a key component in ensuring the seamless integration and function of various engine parts, contributing to the engine’s efficiency and longevity.

Conclusion

The 3178534 Reducing Hexagon Nipple is a vital component in the fluid transfer systems of commercial trucks and Cummins engines. Its design, featuring a hexagonal shape and precise thread specifications, ensures secure and leak-free connections, enhancing the efficiency and reliability of the systems it serves. Regular maintenance and proper installation are crucial to prolong its lifespan and ensure optimal performance. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, making it an indispensable element in the automotive industry.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Dixon, J. C. (1996). Tyres Suspension and Handling Second Edition. SAE International.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.