This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

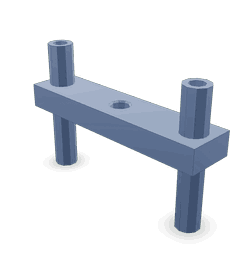

The Cummins 3164307 Installer Fixture is a specialized tool designed for the maintenance and repair of commercial trucks. This fixture is integral to the installation and removal processes of specific truck components, ensuring precision and efficiency in maintenance procedures. Its role in facilitating accurate alignment and secure fitting of parts underscores its significance in the upkeep of commercial vehicles 1.

Purpose and Functionality

The Cummins 3164307 Installer Fixture serves a pivotal role in the installation and removal of truck components. It aids in aligning parts correctly during installation, which is crucial for the proper functioning of the truck’s systems. Additionally, it secures components in place, ensuring they are held firmly during the maintenance process. This fixture is designed to streamline the installation and removal procedures, making them more efficient and less prone to errors 2.

Key Features

The Cummins 3164307 Installer Fixture is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. Key features include a sturdy construction that can withstand the rigors of commercial truck maintenance, precision-machined surfaces for accurate part alignment, and ergonomic design elements that enhance ease of use. These attributes ensure that the fixture not only performs its function effectively but also endures the demands of frequent use in a professional setting 3.

Benefits

Utilizing the Cummins 3164307 Installer Fixture offers several advantages. It enhances the efficiency of maintenance tasks by simplifying the installation and removal processes. The fixture’s design reduces the likelihood of installation errors, which can lead to component malfunction or failure. Furthermore, by ensuring parts are correctly aligned and securely held, it contributes to the overall safety of the repair process, protecting both the vehicle and the technician 4.

Installation and Usage Guidelines

To install and use the Cummins 3164307 Installer Fixture, follow these steps:

- Ensure the work area is clean and free of obstructions.

- Position the fixture according to the manufacturer’s instructions, ensuring it is level and stable.

- Align the truck component with the fixture’s guides or slots.

- Secure the component in place using the fixture’s clamping mechanism.

- Proceed with the installation or removal process as required. Best practices include regularly inspecting the fixture for signs of wear or damage and adhering to safety protocols during use.

Troubleshooting and Maintenance

Common issues with the Cummins 3164307 Installer Fixture may include misalignment of components or difficulty in securing parts. Troubleshooting steps involve checking the fixture for any obstructions or damage and ensuring it is correctly positioned. Regular maintenance, such as cleaning and lubricating moving parts, is recommended to preserve the fixture’s performance and longevity. Inspecting for wear and tear and addressing any issues promptly will help maintain the fixture’s effectiveness.

Manufacturer - Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a broad product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for reliability and performance. The company’s dedication to advancing truck component manufacturing is evident in its products, which are designed to meet the demanding requirements of commercial vehicle maintenance and operation.

Role of 3164307 Installer Fixture in Engine Systems

The 3164307 Installer Fixture is a critical tool designed to facilitate the precise installation of cylinder liners within engine systems. This fixture ensures that the cylinder liners are correctly aligned and securely positioned, which is fundamental for the engine’s performance and longevity.

When integrating the 3164307 Installer Fixture with engine components, it interacts directly with the cylinder block. The fixture holds the cylinder liner in place, allowing for accurate insertion into the cylinder bore. This process is vital for maintaining the structural integrity of the engine, as improper installation can lead to misalignment, increased wear, and potential engine failure.

Additionally, the 3164307 Installer Fixture works in conjunction with other tools and components such as honing machines and alignment tools. These accessories ensure that the cylinder liner is not only correctly positioned but also properly honed to the exact specifications required for optimal engine function. The fixture’s role in this process cannot be overstated, as it provides the stability and precision needed to achieve a flawless fit.

Furthermore, the use of the 3164307 Installer Fixture enhances the efficiency of the installation process. By securing the cylinder liner, it allows mechanics to perform additional tasks such as torqueing the liner into place and verifying its alignment without the risk of movement or misalignment. This results in a more streamlined and reliable installation procedure, ultimately contributing to the overall performance and reliability of the engine system.

Conclusion

The Cummins 3164307 Installer Fixture plays a significant role in the maintenance and repair of commercial trucks by ensuring precise alignment and secure fitting of components. Its robust design, key features, and the benefits it offers make it an indispensable tool in the toolkit of any professional mechanic. Regular maintenance and proper usage of this part are essential to preserve its performance and longevity, ultimately contributing to the efficiency and safety of truck maintenance procedures.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.