The 3164046 Bench Calibration Cable, manufactured by Cummins, is a specialized tool designed for the maintenance and calibration of heavy-duty truck components. Cummins, a well-established name in the heavy-duty truck and engine industry, ensures that this part meets the rigorous demands of professional truck maintenance and calibration processes.

Basic Concepts of Bench Calibration Cables

Bench calibration cables are tools used in the automotive and heavy-duty truck industries to facilitate the calibration of various electronic components. These cables connect diagnostic equipment to the vehicle’s electronic control units (ECUs), allowing for precise adjustments and ensuring that the components operate within specified parameters. They play a role in maintaining the performance and efficiency of truck systems by enabling accurate calibrations 1.

Purpose of the 3164046 Bench Calibration Cable

The 3164046 Bench Calibration Cable is specifically designed to aid in the operation and maintenance of trucks. It is used in diagnostic and calibration procedures to ensure that truck components, particularly electronic control units, are accurately calibrated. This cable allows technicians to perform bench calibrations, which are crucial for maintaining the optimal performance of truck systems 2.

Key Features

The 3164046 Bench Calibration Cable boasts several key features that enhance its functionality. Its robust design ensures durability in demanding environments, while its high-quality build guarantees reliable performance. The cable is engineered to provide a secure connection between diagnostic tools and truck components, facilitating precise calibrations. Additionally, it is designed for ease of use, allowing technicians to perform calibrations efficiently.

Benefits of Using the 3164046 Bench Calibration Cable

Using the 3164046 Bench Calibration Cable offers several advantages. It provides improved accuracy in calibrations, ensuring that truck components operate within the desired parameters. The cable’s ease of use reduces the time required for calibration procedures, leading to increased efficiency. Furthermore, by ensuring accurate calibrations, it can contribute to potential cost savings for fleet operators by reducing the need for frequent repairs and maintenance 3.

Installation and Setup

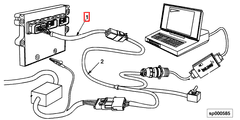

To install and set up the 3164046 Bench Calibration Cable, follow these steps:

- Ensure that the diagnostic equipment and truck components are powered off.

- Connect one end of the cable to the diagnostic equipment.

- Connect the other end to the truck’s electronic control unit.

- Power on the diagnostic equipment and the truck components.

- Configure the diagnostic software to recognize the connected cable.

Operational Guidelines

When using the 3164046 Bench Calibration Cable during calibration processes, adhere to the following guidelines:

- Follow the manufacturer’s instructions for connecting the cable to ensure a secure and proper connection.

- Use the diagnostic software provided by Cummins to perform calibrations.

- Perform calibrations in a controlled environment to avoid interference from external factors.

- Regularly check the cable for any signs of wear or damage to ensure consistent performance.

Troubleshooting Common Issues

Common issues that may arise when using the 3164046 Bench Calibration Cable include connection problems and calibration errors. To troubleshoot these issues:

- Ensure that the cable is securely connected to both the diagnostic equipment and the truck components.

- Check for any damage to the cable that may affect its performance.

- Restart the diagnostic equipment and the truck components to resolve any software-related issues.

- Consult the diagnostic software’s troubleshooting guide for specific error codes and solutions.

Maintenance Tips

To ensure the longevity and consistent performance of the 3164046 Bench Calibration Cable, follow these maintenance tips:

- Regularly inspect the cable for any signs of wear or damage.

- Clean the connectors to remove any dirt or debris that may affect the connection.

- Store the cable in a dry and cool place when not in use to prevent damage from environmental factors.

Safety Considerations

When using the 3164046 Bench Calibration Cable, observe the following safety guidelines:

- Ensure that the diagnostic equipment and truck components are powered off before connecting or disconnecting the cable.

- Handle the cable with care to avoid damaging the connectors or the cable itself.

- Follow all safety instructions provided by Cummins to ensure safe and proper use of the cable.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the heavy-duty truck and engine industry. The company offers a wide range of products and services designed to meet the needs of customers in various industries, ensuring high performance, reliability, and efficiency.

Conclusion

The 3164046 Bench Calibration Cable is an essential tool for maintaining and calibrating heavy-duty truck components. Its robust design, ease of use, and reliable performance make it a valuable asset for technicians and fleet operators. By ensuring accurate calibrations, this Cummins part contributes to the optimal performance and efficiency of truck systems, ultimately leading to cost savings and reduced maintenance needs.

-

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Arora, S., Abkenar, A.T., & Jayasi, S.G. (2021). Heavy-duty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.