This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

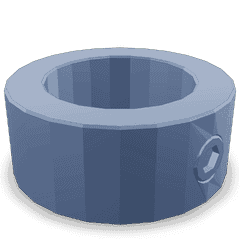

The Cummins 3164039 Stop Collar is a critical component in heavy-duty trucks, designed to ensure the proper operation of the engine by facilitating the correct positioning and movement of other engine components. This part is integral to maintaining the efficiency and reliability of the engine system 1.

Purpose and Function

The primary role of the Cummins 3164039 Stop Collar is to limit the travel of certain engine components, ensuring they do not move beyond their designated range. This limitation is essential for the synchronized operation of the engine, as it prevents undue stress on the components and maintains the precision of engine movements. The stop collar interacts with other parts such as the camshaft and valve train, contributing to the overall stability and performance of the engine 2.

Key Features

The design of the Cummins 3164039 Stop Collar incorporates robust materials that enhance its durability and performance. Typically constructed from high-grade steel, this stop collar is engineered to withstand the high stresses and temperatures encountered in heavy-duty truck engines. Its precise machining ensures a snug fit and reliable operation, while its surface treatment may include coatings to resist corrosion and wear, further extending its service life 3.

Benefits

The Cummins 3164039 Stop Collar offers several advantages. By ensuring components remain within their operational limits, it contributes to improved engine safety and performance. Additionally, its durable construction helps in reducing the frequency of replacements and maintenance, leading to cost savings over time. The reliable operation of the stop collar also aids in prolonging the life of associated engine components 4.

Installation Process

Installing the Cummins 3164039 Stop Collar requires careful attention to detail. The process typically involves:

- Ensuring the engine is cool and the relevant components are accessible.

- Using appropriate tools to remove any old or damaged stop collars.

- Cleaning the installation area to remove any debris or old lubricants.

- Positioning the new stop collar in its designated location, ensuring it is aligned correctly with other components.

- Securing the stop collar in place, following the manufacturer’s torque specifications to avoid over-tightening.

- Rechecking the alignment and operation of the components to confirm proper installation.

Common Issues and Troubleshooting

Typical issues with the Cummins 3164039 Stop Collar may include wear, misalignment, or damage due to extreme conditions. Troubleshooting steps may involve:

- Inspecting the collar for signs of wear or damage.

- Checking the alignment with other components.

- Ensuring proper torque has been applied during installation.

- Replacing the collar if it shows significant wear or if it is damaged.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3164039 Stop Collar, regular maintenance practices should be followed. This includes:

- Periodically inspecting the collar for signs of wear or damage.

- Ensuring it remains properly aligned with other engine components.

- Keeping the installation area clean and free of debris.

- Following the manufacturer’s recommendations for inspection and replacement intervals.

Manufacturer Information

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and robust after-sales support underscore its position as a trusted provider in the automotive and heavy-duty sectors.

Role of Part 3164039 Stop Collar in Engine Systems

The Cummins 3164039 Stop Collar is an essential component in various engine systems, particularly when integrated with a Thread Salvage Kit. Its primary function is to provide a secure and precise stop for threaded components, ensuring that they do not over-extend during operation. This is particularly important in high-stress environments where even minor misalignments can lead to significant issues 5.

When used in conjunction with a Thread Salvage Kit, the Stop Collar helps maintain the integrity of the threads. The Thread Salvage Kit is designed to repair and protect damaged threads, ensuring that connections remain tight and secure. The Stop Collar complements this by preventing excessive movement that could otherwise damage the repaired threads.

In practical applications, the Stop Collar is often found in fuel injection systems, where it ensures that injectors are positioned correctly within their housings. This not only enhances the efficiency of fuel delivery but also prolongs the lifespan of the injectors by reducing wear and tear.

Additionally, in hydraulic systems, the Stop Collar plays a significant role in maintaining the precise alignment of pistons and cylinders. This is vital for the smooth operation of hydraulic presses and actuators, where even a slight misalignment can result in decreased performance or system failure.

Overall, the integration of the Stop Collar with components like the Thread Salvage Kit underscores its importance in maintaining the reliability and efficiency of engine systems.

Conclusion

The Cummins 3164039 Stop Collar is a vital component in heavy-duty truck engines, ensuring the proper operation and longevity of engine systems. Its robust design, precise function, and integration with other components like the Thread Salvage Kit highlight its importance in maintaining engine efficiency and reliability.

-

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISB5.9 CM2880 B110. Bulletin Number 4332885.

↩ -

Cummins Inc. (n.d.). Technical Bulletin on Thread Salvage Kit Integration.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.