This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

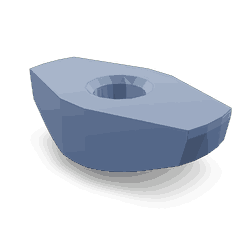

The Cummins 3163822 Remover Jaw is a specialized tool designed for the maintenance and repair of commercial trucks. Engineered to facilitate the removal and installation of various truck components, this part ensures that mechanics can perform their tasks with greater efficiency and safety. It is integral to the maintenance process, providing a reliable solution for handling complex truck parts 1.

Purpose and Functionality

The Cummins 3163822 Remover Jaw serves a specific purpose in truck maintenance by aiding in the extraction and placement of components that are otherwise difficult to manage. It operates through a mechanical design that allows it to grip and manipulate parts securely. This functionality is essential for tasks such as removing and installing bearings, seals, and other components within the truck’s engine and transmission systems. By providing a secure grip, the Remover Jaw ensures that parts can be handled without causing damage, thereby streamlining the maintenance process 2.

Key Features

The Cummins 3163822 Remover Jaw is characterized by several key features that enhance its performance and durability. Its design incorporates high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The jaw mechanism is precision-engineered to provide a firm yet gentle grip on components, minimizing the risk of damage. Additionally, the tool is designed for ease of use, with ergonomic handles that reduce operator fatigue during prolonged use. These features collectively contribute to the Remover Jaw’s effectiveness in truck maintenance applications 3.

Benefits

Utilizing the Cummins 3163822 Remover Jaw offers several advantages in truck maintenance. It increases efficiency by allowing mechanics to remove and install components more quickly and with less effort. The tool’s secure grip reduces the risk of damage to both the components being handled and the surrounding areas. Furthermore, by providing a safer method for component manipulation, the Remover Jaw enhances the overall safety of maintenance procedures, protecting mechanics from potential injuries.

Application in Truck Maintenance

The Cummins 3163822 Remover Jaw is commonly used in various truck maintenance scenarios. It is particularly useful in the removal and installation of bearings and seals within the engine and transmission systems. For example, when performing an engine overhaul, mechanics can use the Remover Jaw to safely extract worn bearings and install new ones, ensuring a precise fit and optimal performance. Similarly, during transmission repairs, the tool aids in the handling of seals and other small components, facilitating a smoother and more efficient repair process.

Troubleshooting and Maintenance

While the Cummins 3163822 Remover Jaw is designed for durability, it may encounter issues over time. Common problems include wear on the jaw mechanism or misalignment of the grip. Troubleshooting steps may involve inspecting the jaw for signs of wear and ensuring that it is properly aligned. Regular maintenance, such as cleaning and lubricating moving parts, can help prolong the tool’s lifespan and maintain its performance. Proper storage in a dry, clean environment is also recommended to prevent corrosion and damage.

Safety Considerations

When using the Cummins 3163822 Remover Jaw, it is important to observe several safety practices. Mechanics should receive proper training on the correct use of the tool to avoid accidents and ensure effective performance. Adhering to safety protocols, such as wearing appropriate personal protective equipment (PPE) and ensuring that the work area is clear of obstacles, is crucial. Additionally, the tool should be inspected regularly for any signs of damage or wear that could compromise its safety and effectiveness.

Integration with Other Tools

The Cummins 3163822 Remover Jaw can be used in conjunction with other tools to enhance truck maintenance procedures. For example, it can be paired with torque wrenches to ensure that components are installed with the correct amount of force. Additionally, using the Remover Jaw alongside diagnostic tools can streamline the process of identifying and addressing issues within the truck’s systems. Compatible tools may include socket sets, pry bars, and specialty wrenches, all of which can work together to facilitate comprehensive truck maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, continually developing new technologies and tools to enhance the performance and reliability of truck components. Cummins’ dedication to excellence is evident in its wide range of products, including the Cummins 3163822 Remover Jaw, which exemplifies the company’s focus on providing high-quality, durable tools for truck maintenance.

Role of Part 3163822 Remover Jaw in Gear Removal Operations

The part 3163822 Remover Jaw is a critical component in the gear removal process, specifically designed to interface with gear removers. Its primary function is to securely grip and hold gears during removal procedures, ensuring stability and precision.

When integrated with a gear remover, the Remover Jaw facilitates the disengagement of gears from their shafts or housings. This is achieved by applying consistent and controlled pressure, which helps in overcoming the frictional forces that bind the gear in place. The Remover Jaw’s design allows for a firm yet non-damaging grip on the gear’s outer surface, preventing any potential damage to the gear teeth or the surrounding components.

In practical applications, the Remover Jaw is often used in conjunction with hydraulic or mechanical gear removers. The hydraulic gear remover utilizes fluid pressure to generate the force required to dislodge gears, while the mechanical gear remover employs a screw-jack mechanism. In both cases, the Remover Jaw plays a pivotal role in transmitting the applied force effectively to the gear, ensuring a smooth and efficient removal process.

Furthermore, the Remover Jaw is engineered to accommodate various gear sizes and types, making it a versatile tool in maintenance and repair operations. Its ability to adapt to different gear configurations enhances its utility across a wide range of applications, from automotive transmissions to industrial machinery.

Conclusion

In summary, the Cummins 3163822 Remover Jaw is a fundamental component in gear removal systems, providing the necessary grip and stability to facilitate the safe and efficient disengagement of gears from their housings. Its integration with other tools and its role in enhancing truck maintenance procedures underscore its importance in the industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.