This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

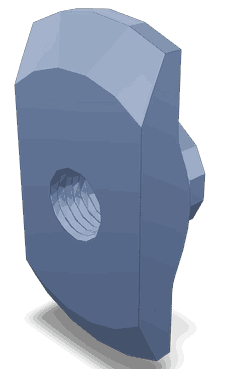

The 3163550 Remover Jaw by Cummins is a specialized tool designed for the maintenance and repair of commercial trucks. Its purpose is to facilitate the removal of various components with precision and efficiency. Cummins Inc., a renowned manufacturer in the automotive industry, produces this tool, leveraging its expertise in diesel engine manufacturing and commitment to high-quality components 1.

Function and Operation

The 3163550 operates through a mechanism that allows it to grip and remove parts securely. It is typically used in scenarios where components are difficult to access or require a firm hold for safe removal. The tool’s design ensures that it can apply the necessary force without damaging the parts being removed, making it invaluable in maintenance and repair operations 2.

Key Features

The primary features of the 3163550 include its robust design, which is constructed from durable materials to withstand the rigors of commercial truck maintenance. Its unique attributes enhance performance, such as the precision grip mechanism that ensures a secure hold on components. Additionally, the tool is designed for ease of use, allowing technicians to operate it efficiently during repairs 3.

Role in Truck Maintenance

In the maintenance and repair processes of commercial trucks, the Remover Jaw plays a significant role by enabling the safe and efficient removal of components. It is commonly applied to parts that are challenging to access or require a strong grip for removal, such as filters, sensors, and other critical components. Its use helps streamline the maintenance process, reducing downtime and enhancing overall efficiency 4.

Benefits

Using the 3163550 offers several advantages, including increased efficiency in part removal, reduction in manual effort required by technicians, and the potential to minimize damage to components during the removal process. These benefits contribute to more effective maintenance operations and help ensure the longevity of truck components 5.

Troubleshooting Common Issues

When using the Remover Jaw, technicians may encounter common issues such as difficulty in gripping components or the tool not fitting properly. To resolve these problems, it is important to ensure the tool is correctly aligned with the component and that it is being operated within its designed parameters. Regular inspection and maintenance of the tool can also help prevent issues and ensure optimal performance 6.

Maintenance Tips

To keep the 3163550 in good working condition, regular maintenance is recommended. This includes cleaning the tool after each use to remove any debris or contaminants, lubricating moving parts to ensure smooth operation, and conducting periodic inspections to check for wear or damage. Following these maintenance tips will help extend the tool’s lifespan and maintain its effectiveness 7.

Safety Considerations

When using the Remover Jaw, it is important to follow safety practices to ensure the well-being of technicians and the integrity of the components being worked on. This includes proper handling of the tool, secure attachment to equipment to prevent accidents, and awareness of potential hazards such as sharp edges or high temperatures. Adhering to these safety considerations will help create a safer work environment 8.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a rich history of innovation and excellence in diesel engine manufacturing. The company is known for its commitment to providing high-quality automotive components and tools, including the 3163550. Cummins’ expertise and dedication to quality make it a trusted name in the industry for professionals seeking reliable and effective solutions for truck maintenance and repair 9.

Role of Part 3163550 Remover Jaw in Engine Systems

In the realm of engine maintenance and repair, the 3163550 is an essential component that facilitates the removal of various engine parts. This component is specifically designed to work in conjunction with camshaft gear removers and general gear removers, enhancing the efficiency and safety of the removal process 10.

When integrated with a Camshaft Gear Remover, the Remover Jaw plays a significant role in securely gripping the camshaft gear. This ensures that the gear can be extracted without causing damage to the surrounding components or the gear itself. The precision fit and robust design of the Remover Jaw allow for a stable and firm hold, which is vital during the removal process.

In the context of a Gear Remover, the Remover Jaw is equally important. It provides the necessary leverage and grip to dislodge gears that are tightly fitted or corroded in place. The jaw’s design is tailored to adapt to different gear sizes and shapes, making it a versatile tool in engine maintenance.

Overall, the 3163550 is a fundamental component in the toolkit of any engineer or mechanic. Its ability to enhance the functionality of gear removers makes it indispensable in the precise and careful extraction of engine components 11.

Conclusion

The 3163550 Remover Jaw by Cummins is a vital tool in the maintenance and repair of commercial trucks, offering precision, efficiency, and safety in the removal of engine components. Its robust design, ease of use, and compatibility with various gear removers make it an indispensable asset for technicians and engineers. Regular maintenance and adherence to safety practices ensure the longevity and effectiveness of this Cummins part, contributing to the overall efficiency of truck maintenance operations.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Cummins Inc. Operation and Maintenance Manual for QSG12 CM2880 G112. Bulletin Number 4388732.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Cummins Inc. Operation and Maintenance Manual for QSG12 CM2880 G112. Bulletin Number 4388732.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.