This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

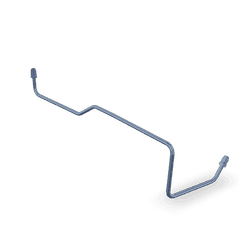

The Cummins 3102386 Pressure Sensing Tube is a component designed to facilitate the monitoring and regulation of pressure within the systems of heavy-duty trucks. Its role is significant in ensuring the efficient operation of these vehicles, contributing to their overall performance and reliability.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are integral components in various automotive systems, designed to monitor and regulate pressure levels. They function by transmitting pressure readings from one part of the system to another, allowing for precise control and adjustment. In the context of heavy-duty trucks, these tubes play a vital role in maintaining optimal pressure levels across different systems, which is essential for the vehicle’s performance and longevity 1.

Purpose and Role in Truck Operation

The Cummins 3102386 Pressure Sensing Tube serves a specific purpose within the operational framework of heavy-duty trucks. It is responsible for accurately conveying pressure readings from the engine or other systems to the monitoring and control units. This accurate transmission of data allows for timely adjustments and interventions, which contribute to the truck’s efficiency, performance, and reliability. By ensuring that pressure levels are maintained within the desired range, the tube helps prevent potential issues that could arise from either too high or too low pressure, thus supporting the truck’s operational integrity 2.

Key Features

The Cummins 3102386 Pressure Sensing Tube is characterized by several key features that enhance its functionality. These include its material composition, which is designed to withstand the harsh conditions typical of heavy-duty truck environments, and its precise design elements that ensure accurate pressure readings. Additionally, the tube may possess unique characteristics that further improve its performance, such as enhanced durability or resistance to wear and tear 3.

Benefits

The advantages provided by the Cummins 3102386 Pressure Sensing Tube are manifold. It offers improved accuracy in pressure monitoring, which is crucial for the efficient operation of the truck’s systems. Enhanced system reliability is another benefit, as the tube’s precise readings help prevent issues that could arise from incorrect pressure levels. Furthermore, by contributing to the truck’s overall efficiency, the tube can lead to potential cost savings for fleet operators, making it a valuable component in the maintenance and operation of heavy-duty trucks.

Installation and Integration

Proper installation and integration of the Cummins 3102386 Pressure Sensing Tube within the truck’s systems are crucial for its effective operation. Guidelines for installation should be followed to ensure compatibility with different truck models and engine types. This careful integration helps maintain the tube’s functionality and the overall performance of the truck.

Troubleshooting and Maintenance

Effective troubleshooting and maintenance practices are key to ensuring the optimal performance and longevity of the Cummins 3102386 Pressure Sensing Tube. Common issues may include inaccurate readings or physical damage to the tube. Routine maintenance, such as regular inspections and cleaning, can help prevent these issues and ensure the tube continues to function correctly.

Safety Considerations

When working with the Cummins 3102386 Pressure Sensing Tube, it is important to observe safety protocols and precautions. Potential hazards may include exposure to high pressure or sharp edges. Effective mitigation strategies, such as wearing appropriate personal protective equipment and following safe handling procedures, can help ensure a safe working environment.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of innovation and commitment to quality. The company’s reputation is built on its dedication to producing reliable and high-performance components, including the Cummins 3102386 Pressure Sensing Tube. This commitment to excellence is evident in the design and functionality of their products, which are trusted by fleet operators worldwide.

Role of Part 3102386 Pressure Sensing Tube in Engine Systems

The 3102386 Pressure Sensing Tube is an integral component in modern engine systems, specifically within the Recirculation and Exhaust systems.

In the Recirculation System, the Pressure Sensing Tube monitors the pressure levels within the recirculation loop. This loop is designed to recirculate a portion of the exhaust gases back into the intake system. By measuring the pressure, the system can adjust the amount of recirculated gases, optimizing combustion efficiency and reducing emissions. The data from the Pressure Sensing Tube is vital for the Engine Control Unit (ECU) to make real-time adjustments, ensuring that the recirculation process is both effective and efficient.

In the Exhaust System, the Pressure Sensing Tube plays a similarly important role. It measures the backpressure in the exhaust manifold, providing essential data to the ECU. This information allows the ECU to fine-tune fuel injection and ignition timing, enhancing overall engine performance and fuel economy. Additionally, accurate pressure readings help in diagnosing potential issues within the exhaust system, such as blockages or leaks, allowing for timely maintenance and repairs.

Overall, the 3102386 Pressure Sensing Tube ensures that both the Recirculation and Exhaust systems operate within optimal parameters, contributing to improved engine performance, efficiency, and emissions control.

Conclusion

The Cummins 3102386 Pressure Sensing Tube is a critical component in the maintenance and operation of heavy-duty trucks. Its accurate pressure monitoring capabilities contribute to the efficient operation of the truck’s systems, enhancing performance, reliability, and efficiency. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this Cummins part.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Allan Bonnick, Elsevier, 2004.

↩ -

Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, Haoran Hu, Simon J Baseley and Xubin Song, SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.