This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

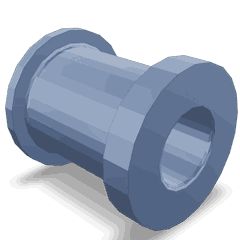

The Cummins 3094088 Wear Pad is a component designed to enhance the maintenance and operation of commercial trucks. Its role is to provide a protective surface that reduces wear and tear on critical engine components, thereby contributing to the overall efficiency and longevity of the vehicle 1.

Basic Concepts of Wear Pads

Wear pads are components used in machinery to protect surfaces from abrasion and wear. They are typically placed in areas where two parts move against each other, such as in engine components or transmission systems. By providing a sacrificial layer, wear pads help extend the life of more expensive or complex parts, ensuring smoother operation and reducing the frequency of required maintenance 2.

Purpose of the 3094088 Wear Pad

The Cummins 3094088 Wear Pad is specifically designed to protect the injector pump in diesel engines. It is positioned to interact with the pump’s moving parts, reducing friction and wear. This placement ensures that the pump operates efficiently and maintains its performance over time, which is vital for the truck’s overall functionality.

Key Features

The Cummins 3094088 Wear Pad is constructed from high-quality materials that offer excellent resistance to wear and corrosion. Its design includes precise dimensions to ensure a perfect fit within the engine assembly. Additionally, the wear pad features a smooth surface that minimizes friction, enhancing the efficiency of the injector pump.

Benefits of Using the 3094088 Wear Pad

Utilizing the Cummins 3094088 Wear Pad offers several advantages. It contributes to improved durability of the injector pump, reduces the need for frequent maintenance, and enhances the operational efficiency of the truck. These benefits lead to lower overall maintenance costs and increased uptime for commercial vehicles.

Installation Process

Installing the Cummins 3094088 Wear Pad involves several steps to ensure proper fit and function. Begin by cleaning the area where the wear pad will be placed to remove any debris or old lubricants. Next, position the wear pad according to the manufacturer’s instructions, ensuring it is aligned correctly with the injector pump. Secure the pad in place using the appropriate fasteners, and then conduct a final inspection to confirm everything is correctly installed.

Troubleshooting Common Issues

Common issues with wear pads include premature wear, misalignment, and damage from improper installation. To address these problems, regularly inspect the wear pad for signs of wear or damage. If misalignment is detected, realign the pad according to the manufacturer’s guidelines. In cases of significant wear or damage, replace the wear pad to prevent further complications.

Maintenance Tips

To ensure the Cummins 3094088 Wear Pad performs optimally, regular maintenance is necessary. Inspect the wear pad during routine engine checks, looking for signs of wear, damage, or misalignment. Clean the area around the wear pad to prevent debris from causing additional wear. Following these maintenance tips will help extend the life of the wear pad and ensure the injector pump operates efficiently.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and quality, providing reliable solutions for a variety of industries, including commercial trucking. The company’s extensive product range and dedication to customer satisfaction underscore its reputation as a leader in the automotive industry.

Cummins Engine Wear Pad 3094088 Compatibility

The Cummins Wear Pad part number 3094088 is designed to fit seamlessly with several engine models, ensuring optimal performance and longevity. This wear pad is engineered to provide essential protection and functionality across a range of Cummins engines.

QST30 CM2350 T101 and QST30 CM552

The Wear Pad 3094088 is compatible with both the QST30 CM2350 T101 and QST30 CM552 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The wear pad ensures that these engines maintain their operational efficiency by reducing wear and tear on critical components.

V903

The Cummins V903 engine also benefits from the Wear Pad 3094088. This engine is typically utilized in various industrial and marine applications, where durability and performance are paramount. The wear pad plays a role in protecting the engine’s internal components, thereby extending the engine’s lifespan and maintaining its performance standards.

By ensuring that the Wear Pad 3094088 is correctly installed in these engines, users can expect enhanced reliability and reduced maintenance costs. This part is a component in the overall maintenance strategy for these Cummins engines.

Role of Part 3094088 Wear Pad in Engine Systems

The 3094088 Wear Pad is a component in various engine systems, contributing to the overall performance and longevity of the engine. Its primary function is to provide a protective interface between moving parts, reducing friction and wear.

In the Electronic Control Module (ECM) Wiring Harness, the Wear Pad ensures that the wiring remains secure and protected from abrasion, maintaining the integrity of the electrical connections.

Within the Filter system, particularly in oil and fuel filters, the Wear Pad helps in smooth operation by minimizing wear on the filter housing and the filter element itself.

For the Oil Bypass system, the Wear Pad is positioned to protect the bypass valve mechanism, ensuring consistent oil flow and pressure regulation.

In Fuel Suction Tubing and Fuel Tubing, the Wear Pad is utilized to prevent damage from vibrations and movement, ensuring a reliable fuel supply to the engine.

The Oil Level Gauge benefits from the Wear Pad by protecting the gauge mechanism from wear, providing accurate and consistent oil level readings.

In the Manifold system, the Wear Pad is employed to protect the manifold from wear due to the movement of connected components, ensuring efficient air and fuel mixture distribution.

For Lubricating Oil Access points, the Wear Pad protects the threads and surrounding areas from wear, facilitating easy and secure access for oil changes and maintenance.

The Module and Engine Control systems utilize the Wear Pad to protect sensitive electronic components from physical wear, ensuring reliable operation.

In Mounting applications, particularly for the Engine Control Module (ECM), the Wear Pad provides a cushion between the module and its mounting surface, protecting both from wear and ensuring a secure fit.

For Plumbing systems involving Compressor Coolant, Fuel, Fuel Filter, and Fuel Supply, the Wear Pad is used to protect fittings and connections from wear, ensuring a leak-free and efficient system.

In Step Hose Mounting applications, the Wear Pad protects the hose and its mounting points from wear, ensuring a secure and durable connection.

Conclusion

The Cummins 3094088 Wear Pad is a vital component for maintaining the efficiency and longevity of commercial truck engines. By reducing friction and wear on critical components, this part ensures smoother operation and lower maintenance costs. Proper installation, regular maintenance, and understanding its compatibility with various engine models are essential for maximizing the benefits of the Cummins 3094088 Wear Pad.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.