This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

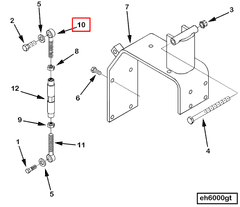

The Cummins 3093625 Eye Bolt is a specialized fastener designed for use in commercial trucks. It serves a role in securing various components and accessories, contributing to the overall functionality and safety of the vehicle. Understanding its purpose and proper application is vital for maintaining the efficiency and reliability of truck operations.

Basic Concepts of Eye Bolts

An eye bolt is a type of fastener characterized by a looped head, which allows for the attachment of ropes, cables, or other rigging equipment. Eye bolts are utilized across multiple industries for lifting, securing, and tensioning applications. Mechanically, the eye bolt functions by providing a secure anchor point, distributing the load evenly through the threaded shaft and into the material it is embedded in 1.

Purpose of the Cummins 3093625 Eye Bolt in Truck Operations

The Cummins 3093625 Eye Bolt is specifically engineered to meet the demanding requirements of commercial truck applications. It is used to secure equipment such as toolboxes, tarps, and other accessories to the truck’s frame or body. This eye bolt plays a role in ensuring that these components remain firmly in place during transit, thereby enhancing both the safety and operational efficiency of the truck 2.

Key Features of the Cummins 3093625 Eye Bolt

The Cummins 3093625 Eye Bolt is designed with several features that make it suitable for heavy-duty applications. It is constructed from high-strength materials to withstand significant loads. The bolt features a robust eye design that provides a secure attachment point and a threaded shaft that allows for easy installation and adjustment. These design elements contribute to its reliability and durability in demanding conditions 3.

Benefits of Using the Cummins 3093625 Eye Bolt

Utilizing the Cummins 3093625 Eye Bolt offers several advantages. Its high load-bearing capacity ensures that it can securely hold heavy accessories without failure. The design of the bolt facilitates straightforward installation, reducing downtime during maintenance. Additionally, its durable construction ensures long-term reliability, even under harsh operating conditions 4.

Installation and Usage Guidelines

Proper installation of the Cummins 3093625 Eye Bolt is crucial for its effective performance. It should be installed in a location that can support the anticipated load, ensuring that the material around the bolt is strong enough to prevent pull-through. Torque specifications should be followed to achieve the correct tension without overtightening, which could damage the bolt or the surrounding material. Using a suitable washer under the bolt head can help distribute the load and prevent damage to the surface 1.

Maintenance and Inspection Tips

Regular maintenance and inspection of the Cummins 3093625 Eye Bolt are necessary to ensure its continued reliability. Inspect the bolt for signs of wear, corrosion, or damage during routine checks. Any detected issues should be addressed promptly to prevent failure. Additionally, ensuring that the attached components are secure and that the bolt remains tight will help maintain its effectiveness over time 2.

Troubleshooting Common Issues

Common issues with eye bolts include loosening due to vibration or dynamic loads, and corrosion from exposure to the elements. To address loosening, re-tighten the bolt to the specified torque and consider using lock washers or thread locker to enhance security. Corrosion can be mitigated by applying a protective coating or replacing the bolt if significant degradation is observed 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the rigorous demands of heavy-duty applications 4.

Cummins Engine Compatibility with Part 3093625

The Eye Bolt part number 3093625, manufactured by Cummins, is designed to fit seamlessly into various Cummins engine models. This part is crucial for securing components and ensuring the structural integrity of the engine. Below is a detailed description of how this part fits into the specified engines:

QSK95 Series

- QSK95 CM2350 K111

- QSK95 CM2350 K113

The Eye Bolt part 3093625 is integral to the QSK95 series engines, specifically the CM2350 K111 and CM2350 K113 models. This part is used in securing the engine’s mounting brackets and other critical components, ensuring they remain firmly in place during operation. The design of the Eye Bolt allows it to withstand the high stresses and vibrations typical of these heavy-duty engines.

QST30 Series

- QST30 CM2350 T101

- QST30 CM552

In the QST30 series, the Eye Bolt part 3093625 is utilized in both the CM2350 T101 and CM552 models. This part is essential for the attachment of various engine components, including the exhaust manifold and other structural elements. The robust construction of the Eye Bolt ensures it can handle the demanding conditions of these engines, providing reliable performance over extended periods.

The Eye Bolt part 3093625 is engineered to meet the stringent requirements of Cummins engines, ensuring compatibility and durability across different engine models. Its design allows for easy installation and removal, facilitating maintenance and repair processes.

Role of Part 3093625 Eye Bolt in Engine Systems

The Part 3093625 Eye Bolt is a versatile component that facilitates the secure attachment and alignment of various engine system components. Its applications span across multiple areas, enhancing the functionality and reliability of the engine.

Adjusting Link

In the context of the adjusting link, the Eye Bolt serves as a pivotal attachment point. It allows for the precise adjustment of tension within the link, ensuring optimal performance and longevity of the connected components. This is particularly important in systems where maintaining consistent tension is essential for efficient operation 1.

Alternator Drive

When integrated into the alternator drive system, the Eye Bolt plays a significant role in securing the drive belt. It provides a stable anchor point that ensures the belt remains properly aligned and tensioned. This is vital for the alternator to function correctly, as any misalignment or improper tension can lead to inefficient power generation and potential damage to the alternator or other components 2.

Alternator Mounting

For alternator mounting, the Eye Bolt is used to secure the alternator to the engine block or mounting bracket. This ensures that the alternator remains firmly in place, even under the vibrations and stresses of engine operation. Proper mounting is essential for the alternator to maintain consistent output and to prevent any movement that could cause electrical issues or mechanical failure 3.

Product Installation Package

In a product installation package, the Eye Bolt is often included to simplify the assembly process. It provides a standardized attachment point that can be used across various components within the package. This not only streamlines the installation process but also ensures that all components are securely fastened, contributing to the overall stability and performance of the engine system 4.

Conclusion

The Cummins 3093625 Eye Bolt is a critical component in the secure attachment and alignment of various engine system components. Its robust design, high load-bearing capacity, and ease of installation make it an essential part for maintaining the efficiency and reliability of commercial truck operations. Regular maintenance and proper installation are key to ensuring its continued performance and durability.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ ↩ ↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ ↩ ↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ ↩ ↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.