3088317

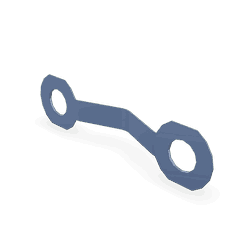

Lockplate

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3088317 Lockplate is a component designed for use in heavy-duty truck applications. It serves a specific function within the mechanical systems of these vehicles, contributing to the overall performance and reliability of the truck. Understanding its purpose and significance is important for maintaining and optimizing the operation of heavy-duty trucks.

Basic Concepts of Lockplates

Lockplates, also known as lock washers, are mechanical components used to prevent fasteners from loosening due to vibration or rotation. They operate by creating additional friction between the fastener and the surface it is securing, thereby enhancing the stability and security of the connection. In mechanical systems, lockplates play a role in ensuring that components remain firmly in place under various operating conditions 1.

Purpose of the Cummins 3088317 Lockplate

The Cummins 3088317 Lockplate is specifically designed to secure fasteners within the engine or transmission system of a truck. Its function is to prevent the loosening of bolts and nuts that are critical to the operation of these systems. By doing so, it helps maintain the integrity of the mechanical connections, ensuring that components remain properly aligned and secured throughout the vehicle’s operation.

Key Features

The Cummins 3088317 Lockplate is characterized by several key features that enhance its performance. It is typically made from a durable material that can withstand the rigors of heavy-duty truck operation. The design of the lockplate includes specific elements that increase its effectiveness in securing fasteners, such as a split design that allows it to grip the fastener and the surface it is securing. These features contribute to the lockplate’s ability to provide reliable fastening solutions in demanding environments.

Benefits

The use of the Cummins 3088317 Lockplate offers several advantages. It improves the security of fasteners by preventing them from loosening, which is particularly important in the high-vibration environment of a heavy-duty truck. This enhanced security contributes to the overall reliability of the truck’s mechanical systems, reducing the risk of component failure or misalignment. Additionally, the lockplate’s resistance to vibration ensures that fasteners remain tight, further supporting the durability and performance of the vehicle 2.

Installation Considerations

Proper installation of the Cummins 3088317 Lockplate is important for ensuring its optimal performance. Guidelines for installation include using the appropriate tools to place the lockplate correctly between the fastener and the surface. It is also important to follow recommended procedures for tightening fasteners to achieve the desired level of security without over-tightening, which could damage the lockplate or the components it is securing.

Troubleshooting and Maintenance

Common issues associated with lockplates include deformation or damage that can reduce their effectiveness. Regular inspection of lockplates for signs of wear or damage is important for identifying potential problems early. Maintenance practices, such as replacing worn lockplates and ensuring that fasteners are properly tightened, can prolong the lifespan and effectiveness of the Cummins 3088317 Lockplate.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of heavy-duty vehicles.

Lockplate 3088317 in Cummins Engines

The Lockplate 3088317, manufactured by Cummins, is a critical component in several of their engine models. This part is integral in ensuring the stability and integrity of the engine’s internal mechanisms.

K19 Engines

In the K19 engine series, the Lockplate 3088317 is used to secure various engine components, maintaining alignment and preventing unwanted movement. Its precise fit and robust construction are essential for the engine’s operational efficiency and longevity.

QSK19 and CM500 Engines

For the QSK19 and CM500 engines, the Lockplate 3088317 serves a similar purpose. These engines, known for their power and reliability, depend on the lockplate to maintain the structural integrity of their components under high stress conditions. The lockplate’s design ensures that all parts remain in their designated positions, contributing to the overall performance and durability of the engine.

The Lockplate 3088317 is engineered to withstand the demanding environments these engines operate in, providing a dependable solution for securing critical engine parts.

Role of Part 3088317 Lockplate in Engine Systems

The part 3088317 Lockplate is an essential component in the secure assembly and operation of various engine systems. It is primarily used to ensure the stability and integrity of connections between different engine components.

In the context of the turbocharger, the Lockplate plays a significant role in securing the turbocharger to the engine. It helps maintain the precise alignment and fastening of the turbocharger, which is vital for efficient air compression and overall engine performance.

When considering the exhaust manifold, the Lockplate is instrumental in securing the manifold to the engine block. This ensures that the manifold remains firmly in place, allowing for the smooth and consistent flow of exhaust gases from the engine cylinders.

In the combined system of the exhaust manifold and turbocharger, the Lockplate is used to secure the turbocharger to the exhaust manifold. This connection is important for maintaining the structural integrity of the system, ensuring that the turbocharger can effectively compress air without any undue stress or movement.

For the exhaust manifold/turbocharger mounting, the Lockplate is essential in providing a stable connection point. It ensures that the turbocharger is mounted securely to the exhaust manifold, which is critical for the efficient operation of the turbocharger and the overall exhaust system.

In the exhaust manifold mounting system, the Lockplate helps in securing the manifold to the engine or other structural components. This ensures that the manifold remains in the correct position, facilitating the proper flow of exhaust gases and reducing the risk of leaks or structural failure.

When dealing with the exhaust mounting manifold, the Lockplate is used to secure the manifold to the exhaust system. This connection is important for maintaining the structural integrity of the exhaust system and ensuring that exhaust gases are directed away from the engine efficiently.

Finally, in the broader context of the manifold system, whether intake or exhaust, the Lockplate is used to secure the manifold to the engine or other components. This ensures that the manifold remains in the correct position, allowing for the efficient flow of air or exhaust gases and contributing to the overall performance and reliability of the engine.

Conclusion

The Cummins 3088317 Lockplate is a vital component in the maintenance and operation of heavy-duty trucks, particularly in securing critical engine and transmission components. Its design and features are tailored to withstand the demanding conditions of heavy-duty truck operation, ensuring the stability and integrity of mechanical connections. Proper installation, regular maintenance, and timely replacement of worn lockplates are essential practices for maximizing the performance and reliability of heavy-duty vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.