This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

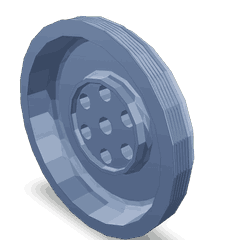

The Cummins 3084031 Crankshaft Pulley is a component designed for use in commercial truck engines. It plays a significant role in the operation of these engines by facilitating the transfer of rotational force from the crankshaft to various engine accessories. Understanding its function and importance can provide insights into the overall efficiency and reliability of truck engines.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a device attached to the front of an engine’s crankshaft. Its primary function is to drive engine accessories such as the alternator, power steering pump, and air conditioning compressor through a series of belts or chains. The pulley helps maintain the smooth operation of these accessories by reducing vibrations that occur during engine operation. It interacts closely with the crankshaft, ensuring that the rotational energy produced by the engine is effectively transmitted to the accessories that require it 1.

Purpose of the Cummins 3084031 Crankshaft Pulley

This Cummins part is integral to the operation of a truck engine. It plays a role in driving various engine accessories by transferring rotational force from the crankshaft. This transfer ensures that components such as the alternator, which generates electrical power, and the water pump, which aids in engine cooling, operate efficiently. The pulley’s design allows it to manage the high torque and speed variations typical in commercial truck engines, contributing to the overall performance and durability of the engine 2.

Key Features

The Cummins 3084031 Crankshaft Pulley is constructed with a focus on durability and performance. It is made from high-quality materials that can withstand the rigors of commercial truck operation. The pulley features a robust design that includes precision-machined surfaces for optimal belt engagement and reduced slippage. Additionally, it may incorporate damping elements to absorb vibrations, enhancing the smoothness of engine operation. These features contribute to the pulley’s longevity and reliability in demanding applications.

Benefits of Using the Cummins 3084031 Crankshaft Pulley

Utilizing this part offers several advantages. It contributes to improved engine efficiency by ensuring that accessories receive the necessary rotational force to operate effectively. The pulley’s design enhances the reliability of the engine by minimizing vibrations and wear on connected components. Furthermore, its compatibility with Cummins engines ensures that it meets the specific requirements and performance standards of these engines, providing a seamless integration into the engine system.

Installation Considerations

Proper installation of the Cummins 3084031 Crankshaft Pulley is vital for ensuring optimal performance and longevity. Installation procedures should follow manufacturer guidelines to ensure correct alignment and secure attachment to the crankshaft. It may be necessary to use special tools to properly install the pulley, ensuring that it is correctly positioned and tightened to the specified torque settings. Attention to detail during installation can prevent issues such as misalignment or looseness, which could lead to decreased performance or damage to the pulley and connected components.

Maintenance and Troubleshooting

Maintaining the Cummins 3084031 Crankshaft Pulley is important for ensuring its continued performance and durability. Regular inspections should be conducted to check for signs of wear, damage, or misalignment. Belts or chains driven by the pulley should be inspected for proper tension and condition, as loose or worn belts can lead to inefficient accessory operation. Common issues that may arise include vibration, noise, or accessory malfunction, which can often be traced back to the pulley. Troubleshooting steps may involve checking for proper installation, inspecting for damage, and ensuring that all connected components are in good working order.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice for commercial truck operators worldwide.

Crankshaft Pulley Fitment for Cummins Part 3084031

The Cummins part number 3084031, identified as a Crankshaft Pulley, is designed to fit a variety of engine models. This pulley is a crucial component that ensures the smooth operation of the engine’s accessory belt system, which drives essential components such as the alternator, water pump, and air conditioning compressor.

G855 and G855 CM558

The G855 and G855 CM558 engines are part of the Cummins G Series, which are known for their reliability and efficiency in various applications. The 3084031 Crankshaft Pulley is specifically engineered to fit these models, ensuring compatibility with the engine’s design and operational requirements.

GTA855 CM558 (CM2358) G101

The GTA855 CM558 (CM2358) G101 engine is another variant within the Cummins G Series. This engine is designed for heavy-duty applications and is often found in industrial and construction equipment. The 3084031 Crankshaft Pulley is compatible with this engine, providing the necessary functionality to maintain the belt system’s integrity and performance.

N14 CELECT PLUS and N14 G

The N14 CELECT PLUS and N14 G engines are part of the Cummins N Series, which are widely used in on-highway and vocational applications. The 3084031 Crankshaft Pulley is designed to fit these engines, ensuring that the accessory belt system operates efficiently and reliably. This compatibility is critical for maintaining the engine’s performance and longevity.

Role of Part 3084031 Crankshaft Pulley in Engine Systems

The Part 3084031 Crankshaft Pulley is an integral component in the synchronization and operation of various engine systems. It serves as the primary driver for several auxiliary components, ensuring their efficient and reliable performance.

Interaction with the Damper

The Crankshaft Pulley is directly connected to the engine’s crankshaft, which experiences significant torsional vibrations due to the combustion process. To mitigate these vibrations, the pulley often incorporates a damper. The damper absorbs and dissipates the torsional energy, preventing it from being transmitted to other engine components. This results in smoother operation, reduced wear on the crankshaft, and enhanced overall engine stability.

Vibration Management

In addition to the damper, the Crankshaft Pulley plays a key role in managing engine vibrations. By maintaining a consistent rotational speed and minimizing fluctuations, the pulley helps in stabilizing the engine’s operation. This is particularly important in high-performance engines where precision and reliability are paramount. The pulley’s design ensures that the vibrations are kept to a minimum, contributing to the longevity and efficiency of the engine.

Driving Auxiliary Components

The Crankshaft Pulley is responsible for driving several auxiliary components through the serpentine belt or timing belt system. These components include the alternator, power steering pump, air conditioning compressor, and water pump. By providing a consistent and reliable source of rotational force, the pulley ensures that these components operate efficiently and without interruption. This is essential for maintaining the engine’s cooling, electrical supply, and overall performance.

Enhancing Engine Performance

Through its interactions with the damper and its role in vibration management, the Crankshaft Pulley significantly enhances engine performance. By ensuring smooth operation and reliable drive for auxiliary components, it contributes to the engine’s durability, efficiency, and overall effectiveness. Engineers and mechanics must understand these interactions to maintain and optimize engine systems for peak performance.

Conclusion

The Cummins 3084031 Crankshaft Pulley is a critical component in the operation of commercial truck engines. Its role in transferring rotational force to engine accessories, managing vibrations, and ensuring the smooth operation of auxiliary components contributes to the overall efficiency and reliability of the engine. Proper installation, maintenance, and understanding of its functions are essential for maximizing the performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.