This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3075324 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is integral to ensuring the reliable operation of the truck’s electrical systems, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays, designed to transmit electrical power and signals throughout a vehicle. It simplifies the installation process by bundling multiple wires together, reducing the risk of tangling and damage. Within a vehicle’s electrical system, the wiring harness plays a role in connecting the battery to various electrical components, such as lights, sensors, and control units, ensuring they receive the necessary power and signals to function correctly 1.

Role of the 3075324 Wiring Harness in Truck Operation

The Cummins 3075324 Wiring Harness is specifically engineered to integrate into the electrical system of commercial trucks. It connects to various components and systems, including the engine control module (ECM), sensors, and actuators. By providing a structured pathway for electrical signals and power, this wiring harness supports the operation of critical truck functions, such as engine management, lighting, and diagnostic systems. Its design ensures efficient and reliable electrical distribution, contributing to the truck’s overall performance and operational efficiency 2.

Key Features

The Cummins 3075324 Wiring Harness is characterized by its robust design and high-quality materials, which enhance its performance and durability. It is constructed using materials that resist corrosion and wear, ensuring longevity even in harsh operating conditions. The harness features precise wiring and secure connections, minimizing the risk of electrical faults. Additionally, its design allows for easy integration with the truck’s existing electrical system, facilitating straightforward installation and maintenance.

Benefits of Using the 3075324 Wiring Harness

Utilizing the Cummins 3075324 Wiring Harness offers several advantages for truck operations. It contributes to improved reliability by ensuring stable and consistent electrical connections. This stability enhances the efficiency of the truck’s electrical systems, leading to better overall performance. Moreover, the harness’s durable construction and secure connections play a role in enhancing safety by reducing the likelihood of electrical failures that could lead to operational hazards 3.

Installation Considerations

When installing the Cummins 3075324 Wiring Harness, it is important to consider compatibility with the specific truck model and its electrical system. Proper installation involves ensuring that all connections are secure and that the harness is correctly routed to avoid damage from heat, friction, or moving parts. Following manufacturer guidelines and using the appropriate tools can help achieve a successful installation, ensuring the harness functions as intended within the truck’s electrical system.

Maintenance and Troubleshooting

Maintaining the Cummins 3075324 Wiring Harness involves regular inspections for signs of wear, corrosion, or damage. Cleaning the harness and ensuring connections remain secure can help prevent electrical issues. In the event of a malfunction, troubleshooting may involve checking for loose connections, inspecting wires for damage, and testing electrical continuity. Addressing issues promptly can help maintain the harness’s performance and the truck’s operational efficiency.

Safety Precautions

When working with the Cummins 3075324 Wiring Harness, observing electrical safety guidelines is paramount. This includes ensuring the truck’s battery is disconnected before beginning any work to prevent electrical shocks. Additionally, using insulated tools and wearing protective gear can help safeguard against accidents. Proper handling and storage of the wiring harness, away from heat sources and corrosive materials, are also important to maintain its integrity and safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient components for a wide range of applications, including commercial trucks. The company’s dedication to advancing technology and improving product performance underscores its position as a leader in the automotive and heavy-duty truck parts industry 4.

Compatibility with K19, K38, and K50 Engines

The Cummins Wiring Harness part number 3075324 is designed to ensure seamless electrical connectivity and communication within the engine’s system. This wiring harness is engineered to fit various Cummins engines, including the K19, K38, and K50 models.

For the K19 and K38 engines, the wiring harness 3075324 is specifically tailored to manage the electrical demands and configurations of these engines. It ensures that all necessary electrical connections are made efficiently, supporting the engine’s operation and performance. The harness is designed to withstand the operational stresses and environmental conditions these engines typically encounter, providing reliable and durable performance.

In the case of the K50 engine, the wiring harness 3075324 is equally important. This engine, known for its robust performance, requires precise and reliable electrical connections to maintain optimal functionality. The harness is engineered to integrate smoothly with the K50’s electrical architecture, ensuring that all components receive the necessary power and signals to operate correctly.

Overall, the Cummins Wiring Harness 3075324 is a versatile and essential part for the K19, K38, and K50 engines, ensuring that these engines can perform at their best by maintaining reliable electrical connectivity.

Role in Engine Systems

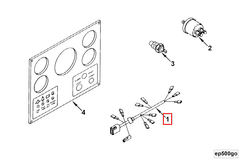

The Cummins 3075324 Wiring Harness is an integral component in the electrical architecture of modern engine systems. It serves as the vital conduit that facilitates the seamless flow of electrical signals and power between various engine components and the Instrument Panel.

Integration with the Instrument Panel

The Wiring Harness connects directly to the Instrument Panel, ensuring that all gauges and indicators receive the necessary electrical signals to display engine performance metrics accurately. This includes data from the engine’s sensors, such as temperature, oil pressure, and RPM, which are critical for the driver’s awareness and decision-making.

Connection to Engine Instruments

Within the engine compartment, the Wiring Harness interfaces with multiple Engine Instruments. These instruments include sensors and actuators that monitor and control various engine functions. The harness provides the electrical pathways needed for these components to communicate with the Engine Control Unit (ECU) and other control systems.

Role in Engine Instrumentation

The Wiring Harness plays a significant role in the operation of Engine Instruments by:

- Transmitting Sensor Data: It carries signals from engine sensors to the ECU, allowing for real-time monitoring and adjustment of engine parameters.

- Powering Actuators: It supplies power to actuators that control functions such as fuel injection, ignition timing, and variable valve timing.

- Ensuring Signal Integrity: The harness is designed to minimize electrical interference, ensuring that the signals transmitted are accurate and reliable.

Supporting Overall System Functionality

By providing a robust and organized electrical connection framework, the Wiring Harness supports the overall functionality and reliability of the engine system. It enables the synchronization of various subsystems, ensuring that the engine operates efficiently and within specified parameters.

Conclusion

In summary, the Cummins 3075324 Wiring Harness is essential for the electrical integration and communication between the Instrument Panel, Engine Instruments, and other critical components within the engine system. Its proper installation and maintenance are key to ensuring the engine’s optimal performance and longevity.

-

Reif, Konrad. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Parikyan, Tigran. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.