This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

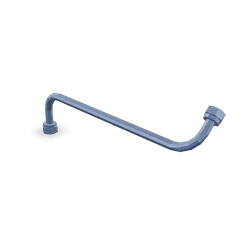

The Compressor Water Inlet Tube, part number 3074370, is a component manufactured by Cummins, a renowned entity in the automotive industry, particularly for its heavy-duty truck engines. This tube is integral to the engine’s cooling system, ensuring optimal performance and longevity of the engine components.

Function and Operation

The Compressor Water Inlet Tube directs water into the compressor section of the engine. This process is vital for maintaining the compressor’s temperature within operational limits. As the engine operates, the compressor can generate significant heat. The inlet tube facilitates the flow of coolant, which absorbs excess heat, thereby regulating the compressor’s temperature and ensuring efficient operation 1.

Purpose of the Compressor Water Inlet Tube

In the context of a heavy-duty truck, this Cummins part plays a specific role in enhancing engine efficiency and performance. By effectively managing the temperature of the compressor, it contributes to the overall stability and reliability of the engine. This temperature regulation is crucial for preventing overheating, which can lead to reduced efficiency and potential engine damage 2.

Key Features

The Compressor Water Inlet Tube is characterized by several key features that enhance its functionality. It is typically made from durable materials resistant to corrosion and high temperatures, ensuring longevity and reliability. The design of the tube is tailored to fit precisely within the engine’s cooling system, allowing for efficient water flow. Additionally, it may include specific connectors or fittings that ensure a secure and leak-free connection to other components in the cooling system.

Benefits

The advantages of the Compressor Water Inlet Tube include improved engine cooling, which is directly linked to increased engine durability and performance. Effective cooling prevents overheating, which can cause engine components to wear out more quickly. Furthermore, by maintaining optimal operating temperatures, the tube contributes to the engine’s overall efficiency, potentially leading to better fuel economy and reduced emissions 3.

Installation Process

Installing the Compressor Water Inlet Tube requires careful attention to detail. The process involves disconnecting the old tube, ensuring the area is clean and free from debris, and then securely fitting the new tube into place. It is important to follow the manufacturer’s guidelines for torque specifications when tightening connections to prevent leaks. Additionally, verifying the correct alignment and fit of the tube within the engine’s cooling system is crucial for optimal performance.

Common Issues and Troubleshooting

Typical problems associated with the Compressor Water Inlet Tube may include leaks, blockages, or corrosion. Leaks can often be traced to loose connections or damaged fittings, which may require re-tightening or replacement. Blockages can impede water flow and are usually addressed by cleaning or replacing the tube. Corrosion, while less common due to the material’s resistance, can be mitigated through regular maintenance and inspection.

Maintenance Tips

To ensure the longevity and optimal performance of the Compressor Water Inlet Tube, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the tube and its connections can prevent blockages and ensure efficient water flow. Additionally, adhering to the manufacturer’s recommended maintenance schedule for the engine’s cooling system can help identify potential issues before they lead to more significant problems.

Cummins Overview

Cummins, the manufacturer of the Compressor Water Inlet Tube, has a rich history in the automotive industry, particularly in the production of heavy-duty truck components. Known for its commitment to quality and innovation, Cummins offers a wide range of products designed to meet the demanding requirements of commercial vehicles. The company’s reputation for reliability and performance makes its components, including the Compressor Water Inlet Tube, a preferred choice for many in the industry.

Conclusion

The Compressor Water Inlet Tube (part 3074370) is a vital component in the engine’s cooling system, ensuring optimal performance and longevity of the engine components. Its role in maintaining the compressor’s temperature within operational limits is crucial for the engine’s efficiency and reliability. Regular maintenance and proper installation are key to ensuring the seamless operation of the cooling system and the sustained performance of the compressor.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.