This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3074287 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a link in the electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is integral to the efficient and reliable operation of the vehicle, ensuring that all electrical systems function as intended.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce the risk of short circuits. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for distributing power and signals to various components, such as lights, sensors, and control units 1.

Purpose of the 3074287 Wiring Harness

The 3074287 Wiring Harness is designed to integrate seamlessly with the electrical systems of commercial trucks. It connects the truck’s battery to its electrical components, ensuring that power is distributed efficiently. This harness also plays a role in facilitating communication between different systems, such as the engine control unit and various sensors, by providing a reliable pathway for electrical signals.

Key Features

The 3074287 Wiring Harness is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the harsh conditions often encountered in commercial truck operations, including exposure to vibrations, temperature fluctuations, and moisture. The harness features durable connectors and is often coated to enhance its resistance to environmental factors. These characteristics contribute to its performance and longevity 2.

Benefits

The use of the 3074287 Wiring Harness in commercial trucks offers several advantages. It enhances the reliability of the electrical system by providing a secure and organized method for power distribution. This leads to improved efficiency, as electrical components receive consistent and adequate power. Additionally, the harness contributes to safety by reducing the risk of electrical faults and ensuring that all systems operate correctly.

Installation Process

Installing the 3074287 Wiring Harness requires careful attention to detail to ensure proper function and safety. The process involves disconnecting the battery to prevent electrical shocks, routing the harness through the truck’s chassis to avoid interference with other components, and securing it in place with ties or brackets. Each connection must be made according to the manufacturer’s specifications to ensure a secure and reliable electrical connection.

Maintenance and Care

To ensure the longevity and optimal performance of the 3074287 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and cleaning the harness to remove any dirt or debris that could affect its performance. Regular checks can help identify potential issues before they lead to more significant problems.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, or corrosion at connection points. These problems can lead to electrical faults or system failures. Addressing these issues involves inspecting the harness for visible damage, tightening or replacing loose connections, and cleaning or repairing corroded areas. In some cases, replacing sections of the harness may be necessary to restore full functionality.

Safety Considerations

When working with the 3074287 Wiring Harness, it is important to follow electrical safety practices. This includes disconnecting the battery before beginning any work to prevent electrical shocks, using insulated tools to avoid short circuits, and ensuring that all work is done in a well-lit and ventilated area. Adhering to these safety protocols helps protect both the technician and the vehicle’s electrical system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations 3.

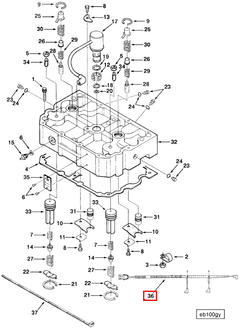

Wiring Harness (Part 3074287) Compatibility with Cummins Engines

The Wiring Harness part number 3074287, manufactured by Cummins, is a critical component in ensuring the electrical systems of various Cummins engines function correctly. This wiring harness is designed to integrate seamlessly with several engine models, facilitating efficient power distribution and communication between different engine systems.

N14 Celect Plus Engines

The N14 Celect Plus engine series is one of the prominent models that benefit from the 3074287 Wiring Harness. This engine is widely used in heavy-duty applications, including trucks and industrial machinery, where reliable power and performance are paramount. The wiring harness ensures that all electrical components, such as sensors, actuators, and control modules, are properly connected and can communicate effectively with the engine control unit (ECU).

Integration and Functionality

The integration of the 3074287 Wiring Harness with the N14 Celect Plus engine involves several key steps:

-

Mapping Electrical Connections: The harness is designed to match the specific electrical requirements of the N14 Celect Plus engine. This includes connections to the ECU, various sensors, and other electrical components.

-

Ensuring Robustness: Given the demanding environments in which these engines operate, the wiring harness is constructed with durable materials to withstand vibrations, temperature fluctuations, and exposure to elements such as moisture and dust.

-

Facilitating Diagnostics: The harness is engineered to support diagnostic functions, allowing for easy troubleshooting and maintenance. This is crucial for ensuring the engine operates at peak efficiency and for minimizing downtime.

-

Customization for Specific Applications: Depending on the application, the wiring harness may be customized to include additional connectors or wiring for specific functionalities, such as auxiliary equipment or specialized monitoring systems.

By ensuring a precise and reliable connection between the engine’s electrical components, the 3074287 Wiring Harness plays a vital role in the overall performance and longevity of the N14 Celect Plus engine.

Role of Part 3074287 Wiring Harness in Engine Systems

The 3074287 Wiring Harness is an integral component in the electrical system of various engine setups, facilitating the seamless operation of multiple subsystems. Its primary function is to provide a structured and reliable pathway for electrical signals and power between different components.

Integration with Brake Systems

In brake systems, the wiring harness ensures that the brake control module receives the necessary signals from the engine control unit (ECU). This allows for precise modulation of braking force, enhancing both safety and performance. The harness also supports the integration of advanced features such as anti-lock braking systems (ABS) and electronic brake distribution (EBD).

Engine Control and Performance

For engine control, the 3074287 Wiring Harness plays a significant role in connecting the ECU to various sensors and actuators. This includes components like the throttle position sensor, oxygen sensors, and fuel injectors. By providing a consistent and interference-free pathway for data, the harness ensures that the ECU can make real-time adjustments to engine parameters, optimizing performance and fuel efficiency.

Engine Brake Systems

In engines equipped with an engine brake, the wiring harness is essential for coordinating the activation and deactivation of the brake. It connects the engine brake control module to the ECU, allowing for smooth transitions between normal engine operation and engine braking. This is particularly important in heavy-duty applications where engine braking is used to control vehicle speed on descents.

Cummins Engine Brake Kit

When integrated with a Cummins Engine Brake Kit, the 3074287 Wiring Harness ensures that all electrical connections are secure and efficient. It links the brake kit’s control module to the engine’s ECU, enabling features like Jake Brake or compression release engine braking. This enhances the vehicle’s ability to manage speed and load, especially in commercial trucking applications.

Wiring Harness Mounting Kit

The inclusion of a Wiring Harness Mounting Kit alongside the 3074287 Wiring Harness ensures that all electrical connections are securely fastened and protected from physical damage. This kit typically includes brackets, clips, and fasteners that keep the harness in place, reducing the risk of chafing, abrasion, or accidental disconnection.

Conclusion

Overall, the 3074287 Wiring Harness is a foundational element in the electrical architecture of modern engine systems, ensuring that all connected components operate in unison for optimal performance and reliability.

-

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.