This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

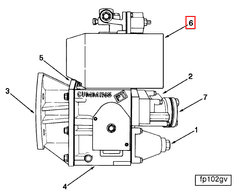

Introduction

The Pressure-Time Pacer Module 3071374, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This module is essential for maintaining the performance and reliability of commercial trucks by regulating and maintaining pressure within the truck’s systems 1.

Function and Operation

This Cummins part operates by monitoring and adjusting pressure levels over time to ensure consistent performance of various truck components. Its role in maintaining optimal pressure is vital for the efficient operation of the truck’s systems 2.

Purpose of the Pressure-Time Pacer Module

The primary function of this part is to ensure the efficient and reliable performance of the truck’s systems by maintaining consistent pressure. This helps in preventing system failures and enhancing the overall functionality of the truck 3.

Key Features

The Pressure-Time Pacer Module 3071374 is designed with robust construction using high-quality materials, ensuring durability and reliability. It is also compatible with various truck systems, making it a versatile component in commercial truck operations.

Benefits

The advantages of this part include improved efficiency, reliability, and performance of the truck’s systems. By ensuring consistent pressure, it reduces the risk of system failures and enhances the overall operational efficiency of the truck.

Installation and Integration

Installing and integrating the Pressure-Time Pacer Module into a truck’s system involves following the manufacturer’s guidelines. This may include disconnecting the old module, connecting the new one, and testing the system to ensure it is functioning correctly.

Common Issues and Troubleshooting

Common issues with the Pressure-Time Pacer Module include pressure inconsistencies and module malfunctions. Troubleshooting steps may involve checking the module’s connections, testing the pressure levels, and replacing the module if necessary.

Maintenance and Care

Regular maintenance is recommended to ensure optimal performance and longevity of the Pressure-Time Pacer Module. This may include checking the module’s connections, testing the pressure levels, and replacing the module if it shows signs of wear or malfunction.

Cummins Overview

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins continues to be a trusted name in the commercial truck industry.

Compatibility with Cummins Engines

The Pressure-time Pacer Module (Part 3071374) is designed to enhance the performance and efficiency of specific Cummins engines, particularly the L10 and N14 mechanical engines. It ensures optimal operation and reliability by managing the engine’s fuel injection timing and pressure 4.

L10 Mechanical Engine

In the L10 mechanical engine, this part plays a pivotal role in managing fuel injection timing and pressure, ensuring peak efficiency, reduced fuel consumption, and lower emissions.

N14 Mechanical Engine

For the N14 mechanical engine, the Pressure-time Pacer Module optimizes the fuel injection process, ensuring maximum power and efficiency. Its precise calibration with the N14 engine meets stringent performance standards.

Role in Engine Systems

The Pressure-time Pacer Module is integral in the orchestration of fuel delivery within engine systems. It works with the fuel pump and the fuel top-level assembly pump to maintain consistent fuel pressure, essential for optimal engine performance. This module is also part of the pressure-time pacer conversion kit, designed to retrofit older engine systems with modern fuel management technology, enhancing engine efficiency and responsiveness.

Conclusion

The Pressure-Time Pacer Module 3071374 by Cummins is a sophisticated regulator that ensures the fuel system operates within precise parameters required for efficient and effective engine operation. Its role in maintaining fuel pressure is fundamental to the performance and reliability of the engine’s fuel injection system.

-

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Dixon, J. C. (1996). Tyres Suspension and Handling Second Edition. SAE International.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Cummins Inc. (n.d.). Owners Manual for ISF3.8 CM2220 F110. Bulletin Number 4358481.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.