This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

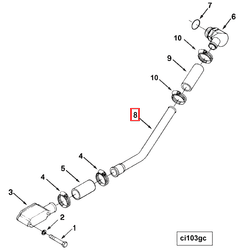

The Compressor Air Inlet Tube, identified by Part #3071183, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the air system of heavy-duty trucks, facilitating efficient air flow to the compressor. Cummins is renowned for its commitment to quality and innovation in automotive components, ensuring that parts like the Compressor Air Inlet Tube meet high standards of performance and reliability 1.

Function and Operation

The Compressor Air Inlet Tube operates by directing air flow from the truck’s air intake system to the compressor. This process is vital for the compressor’s function, as it relies on a steady and unobstructed supply of air to operate efficiently. The tube’s design ensures that air is channeled effectively, minimizing turbulence and maximizing the efficiency of air delivery to the compressor 2.

Purpose of the Compressor Air Inlet Tube

The Compressor Air Inlet Tube plays a specific role in the overall operation of a truck. It contributes to engine performance and efficiency by ensuring that the compressor receives a consistent and adequate supply of air. This, in turn, supports the compressor’s ability to maintain the necessary air pressure for various truck systems, including the brakes and suspension, thereby enhancing overall truck performance 3.

Key Features

The primary features of the Compressor Air Inlet Tube include its material composition, which is designed to withstand the rigors of heavy-duty truck environments. The tube is typically made from durable materials that resist corrosion and wear. Its design elements are tailored to facilitate smooth air flow, with features such as a streamlined shape and precise diameter to match the compressor’s intake requirements. Additionally, any unique attributes, such as reinforced sections or specialized coatings, enhance its functionality and durability.

Benefits

The advantages provided by the Compressor Air Inlet Tube include improved air flow to the compressor, which enhances the compressor’s efficiency. This leads to more consistent air pressure within the truck’s systems, potentially contributing to overall truck performance. The tube’s design and material also contribute to its longevity, reducing the need for frequent replacements and maintenance.

Installation Considerations

For the proper installation of the Compressor Air Inlet Tube, it is recommended to follow manufacturer guidelines. This may include ensuring that the tube is correctly aligned with the compressor’s intake and that all connections are secure. Special considerations might involve checking for any obstructions in the air path and ensuring that the tube is compatible with the specific truck model.

Maintenance and Troubleshooting

Routine maintenance practices for the Compressor Air Inlet Tube include regular inspections for signs of wear, corrosion, or damage. Cleaning the tube to remove any debris that could obstruct air flow is also recommended. Troubleshooting tips might involve checking for leaks in the air system, which could indicate a problem with the tube or its connections.

Common Issues and Solutions

Frequent problems associated with the Compressor Air Inlet Tube can include blockages due to debris, corrosion, or physical damage. Solutions or maintenance actions to address these issues may involve cleaning the tube, applying protective coatings to prevent corrosion, or replacing the tube if it is damaged beyond repair.

Integration with Other Systems

The Compressor Air Inlet Tube interacts with other components within the truck’s air system, such as the compressor and air tanks. The efficiency of these interactions is important for overall system performance, as they ensure that the compressor receives the air it needs to maintain system pressure. This, in turn, supports the operation of critical truck systems, such as the brakes and suspension.

Manufacturer Overview - Cummins

Cummins has a long-standing reputation in the industry for producing high-quality automotive components. Founded with a commitment to innovation and excellence, Cummins continues to be a leader in the design and manufacture of engine and powertrain components. Their products are known for their reliability, performance, and durability, making them a preferred choice for heavy-duty truck applications.

Compatibility of Compressor Air Inlet Tube (Part 3071183) with Cummins Engines

The Compressor Air Inlet Tube, identified by part number 3071183 and manufactured by Cummins, is a crucial component in the air intake system of certain Cummins engines. This part is designed to ensure that the engine receives a steady and clean air supply, which is essential for optimal performance and efficiency.

N14 CELECT PLUS and N14 MECHANICAL Engines

The Compressor Air Inlet Tube (3071183) is compatible with both the N14 CELECT PLUS and N14 MECHANICAL engines. These engines are part of Cummins’ N-Series lineup, which is renowned for its durability and reliability in heavy-duty applications.

N14 CELECT PLUS Engine:

- This engine variant features advanced electronic controls and improved emissions management, making it suitable for applications requiring stringent environmental compliance.

- The Compressor Air Inlet Tube in this engine setup ensures that the air entering the compressor is free from contaminants, which helps in maintaining the efficiency of the electronic control systems.

N14 MECHANICAL Engine:

- The N14 MECHANICAL engine is known for its robust mechanical control systems and straightforward design, making it ideal for applications where simplicity and ease of maintenance are prioritized.

- The Compressor Air Inlet Tube in this engine variant plays a critical role in providing a consistent air flow to the compressor, which is essential for the engine’s mechanical operation and longevity.

Both engine variants benefit from the precise engineering of the Compressor Air Inlet Tube, ensuring that the air intake system functions effectively under various operating conditions. This compatibility underscores the importance of using genuine Cummins parts to maintain the integrity and performance of these engines.

Understanding the Role of Part 3071183 Compressor Air Inlet Tube in Engine Systems

In the intricate arrangement of an engine system, the Compressor Air Inlet Tube, specifically part 3071183, serves a significant function. This component is engineered to facilitate the smooth and efficient flow of air into the compressor section of the engine.

The Compressor Air Inlet Tube is positioned at the front of the engine, where it interfaces with the compressor. Its primary role is to direct ambient air into the compressor with minimal turbulence. This ensures that the air entering the compressor is at an optimal pressure and temperature, which is essential for the efficient operation of the compressor blades.

Moreover, the design of the Compressor Air Inlet Tube contributes to the overall aerodynamics of the engine. By streamlining the airflow, it helps reduce drag and enhances the engine’s performance. The tube is also designed to withstand the high pressures and temperatures associated with the compressor operation, ensuring durability and reliability.

Conclusion

In summary, part 3071183 Compressor Air Inlet Tube is a key component in the engine’s air management system, playing a vital role in the efficient operation of the compressor and the overall performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.