This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

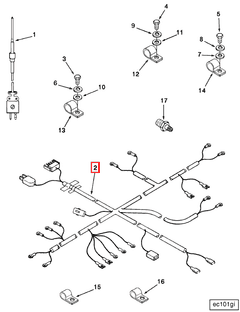

Introduction

The Cummins 3070095 Wiring Harness is a specialized component designed for use in commercial trucks. It plays a role in the vehicle’s electrical system by facilitating the connection between various electrical components and the truck’s power source. This part contributes to the reliable operation of electrical systems within commercial trucks, enhancing overall vehicle performance and safety 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness provides a structured pathway for electricity to flow from the power source to the components that require it, such as lights, sensors, and control units 2.

Purpose of the 3070095 Wiring Harness

The Cummins 3070095 Wiring Harness is specifically engineered to integrate with the electrical systems of commercial trucks. It connects various electrical components, allowing them to communicate and operate in unison. This harness is designed to work alongside other systems and components, ensuring that all electrical functions within the truck are performed efficiently and reliably. Its integration is important for the operation of features such as lighting, engine management, and diagnostic systems.

Key Features

The Cummins 3070095 Wiring Harness is characterized by its robust design and the quality of materials used in its construction. It is built to withstand the harsh conditions often encountered in commercial truck operations, including exposure to vibrations, temperature extremes, and moisture. Unique attributes of this harness include its durable connectors, which are designed to provide secure and lasting connections, and its flexible yet sturdy construction, which allows it to adapt to the complex routing requirements within a truck’s chassis.

Benefits of Using the 3070095 Wiring Harness

Utilizing the Cummins 3070095 Wiring Harness in commercial trucks offers several advantages. It contributes to improved efficiency by ensuring that electrical signals are transmitted quickly and accurately between components. The reliability of this harness helps minimize downtime and maintenance costs by reducing the likelihood of electrical failures. Additionally, its design enhances safety by providing a secure and organized pathway for electrical currents, reducing the risk of short circuits and other hazards 3.

Installation and Integration

When installing the Cummins 3070095 Wiring Harness, it is important to follow guidelines that ensure compatibility with the specific truck model and its electrical systems. Proper installation involves careful routing of the harness to avoid damage and ensure it fits within the truck’s chassis without obstruction. Integration with existing systems requires attention to detail to ensure all connections are secure and function as intended.

Maintenance and Troubleshooting

Maintaining the Cummins 3070095 Wiring Harness involves regular inspections to check for signs of wear, corrosion, or damage. Common issues may include loose connections or damaged wires, which can be identified through visual inspection or diagnostic testing. Troubleshooting techniques may involve tracing electrical pathways to locate faults and making necessary repairs or adjustments to ensure optimal performance.

Safety Considerations

Working with the Cummins 3070095 Wiring Harness requires adherence to safety practices to prevent accidents. This includes ensuring the truck’s electrical system is de-energized before beginning work, using appropriate personal protective equipment, and following manufacturer guidelines for handling and installation. Compliance with industry standards is crucial to maintain safety and operational integrity.

Environmental Impact

The production, use, and disposal of the Cummins 3070095 Wiring Harness have environmental considerations. Cummins is committed to minimizing the ecological footprint of its products through sustainable manufacturing practices, the use of recyclable materials, and efforts to reduce waste. Proper disposal and recycling of wiring harnesses are encouraged to further mitigate environmental impact.

Cummins Overview

Cummins is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications. Cummins’ dedication to excellence and sustainability is evident in its approach to product development and manufacturing.

Cummins Wiring Harness 3070095 Compatibility with K19 Engines

The Cummins Wiring Harness part number 3070095 is designed to seamlessly integrate with the K19 engine series. This wiring harness ensures the proper electrical connectivity between various engine components and the vehicle’s electrical system. It is engineered to meet the specific electrical requirements of the K19 engines, providing reliable and efficient power distribution.

The K19 engine series, known for its robust performance and durability, benefits significantly from the precise and high-quality wiring harness. The harness is crafted to withstand the demanding conditions of engine operation, ensuring longevity and consistent performance. Its design allows for easy installation and maintenance, making it a preferred choice for both original equipment manufacturers (OEMs) and aftermarket applications.

In the context of the K19 engines, the wiring harness 3070095 plays a pivotal role in maintaining the integrity of the engine’s electrical system. It connects essential components such as sensors, actuators, and control modules, facilitating the smooth operation of the engine. The harness is engineered to handle the electrical load efficiently, reducing the risk of electrical faults and enhancing overall engine reliability.

For users and technicians working with K19 engines, understanding the compatibility and functionality of the Cummins Wiring Harness 3070095 is crucial. This part is designed to fit perfectly within the engine’s architecture, ensuring that all electrical connections are secure and reliable. Its compatibility with the K19 series underscores Cummins’ commitment to providing high-quality components that enhance engine performance and durability.

Role of Part 3070095 Wiring Harness in Engine Systems

The Part 3070095 Wiring Harness is an integral component in the electrical architecture of modern engine systems. It serves as the backbone for the electrical connections that facilitate communication and power distribution among various engine components.

Integration with Accessories

The wiring harness interfaces with various vehicle accessories, ensuring they receive the necessary power and signals to operate correctly. This includes components such as the air conditioning system, power windows, and audio systems. By providing a structured pathway for electrical signals, the harness ensures that these accessories function seamlessly with the engine’s operation.

Electrical System Coordination

In the broader electrical system, the Part 3070095 Wiring Harness plays a significant role in coordinating the flow of electricity. It connects the battery to the starter motor, ignition system, and other critical electrical components. This ensures that all systems are powered appropriately and that the engine can start and run efficiently.

Engine Wiring

The harness is deeply involved in the engine wiring, linking the engine control module (ECM) to sensors and actuators throughout the engine. This includes connections to the oxygen sensors, throttle position sensor, and various solenoids. Accurate and reliable wiring is essential for the ECM to monitor and adjust engine performance in real-time.

Harness and Engine Control Wiring

As a core element of the engine control wiring, the Part 3070095 Wiring Harness ensures that all control signals are transmitted accurately between the ECM and the engine components. This includes data from the crankshaft position sensor, camshaft position sensor, and other critical inputs that the ECM uses to manage fuel injection, ignition timing, and emissions control.

Instrument Panel Integration

The wiring harness also extends to the instrument panel, providing the necessary connections for gauges and warning lights. This allows the driver to monitor engine performance and receive alerts for any issues that may arise. The harness ensures that all signals from the engine sensors are accurately displayed on the instrument panel, enhancing driver awareness and safety.

Conclusion

In summary, the Part 3070095 Wiring Harness is a vital component that ensures the seamless operation of the engine and its associated systems by providing reliable electrical connections and signal pathways. Its robust design, compatibility with various engine systems, and role in enhancing engine performance and safety make it an essential part of modern vehicle electrical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.