This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3067880 Wiring Harness, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This part facilitates the electrical connections necessary for various systems to operate efficiently in commercial trucks.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and components that transmit electrical power and signals throughout a vehicle. It consists of insulated wires bundled together, often secured with ties or conduits, and includes connectors that link to various electrical components. The harness plays a role in the vehicle’s electrical system by ensuring that power and data are distributed correctly to all necessary parts, from the engine control unit to lighting and auxiliary systems 1.

Purpose of the 3067880 Wiring Harness

This Cummins part is designed specifically for use in commercial trucks. It plays a role in the truck’s electrical system by providing the necessary connections for the engine, transmission, and other critical systems. Its integration with these systems allows for efficient communication and power distribution, which is vital for the truck’s overall performance and functionality 2.

Key Features

The 3067880 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed to withstand the demanding conditions of commercial truck operations. Key features include durable insulation to protect against abrasion and environmental factors, precise connectors for secure and reliable connections, and a layout that minimizes the risk of electrical interference 3.

Benefits

This part offers several advantages. It contributes to improved efficiency by ensuring that electrical connections are secure and reliable. This reliability enhances the overall performance of the truck’s systems. Additionally, the harness is designed to be safe, reducing the risk of electrical faults that could lead to safety hazards 4.

Installation Considerations

When installing the 3067880 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s systems. This may include checking for compatibility with the truck’s make and model, using the appropriate tools for installation, and ensuring that all connections are secure and correctly aligned.

Troubleshooting Common Issues

Common issues with this part may include electrical faults or connectivity problems. To address these, it is important to conduct a systematic inspection of the harness and its connections. This may involve checking for signs of wear or damage, ensuring that all connectors are properly seated, and testing the electrical continuity to identify any breaks or shorts in the wiring.

Maintenance Tips

Regular maintenance of the 3067880 Wiring Harness is important to ensure its longevity and optimal performance. This includes inspecting the harness for signs of wear or damage, cleaning connectors to prevent corrosion, and ensuring that all connections remain secure. Adhering to a maintenance schedule can help prevent issues and extend the life of the harness.

Safety Precautions

When working with the 3067880 Wiring Harness, it is important to observe safety measures. This includes ensuring that the truck’s battery is disconnected before beginning any work to prevent the risk of electrical shock. Additionally, it is important to handle the harness with care to avoid damage to the wires or connectors.

Cummins: A Brief Overview

Cummins is a reputable manufacturer with a long history in the production of automotive components. Known for their commitment to quality, Cummins products are designed to meet the rigorous demands of commercial and heavy-duty applications. Their reputation is built on a foundation of innovation, reliability, and customer satisfaction, making them a trusted name in the industry.

Cummins Wiring Harness 3067880 Compatibility with Engine Models

The Cummins Wiring Harness part number 3067880 is designed to integrate seamlessly with various engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to meet the specific electrical requirements of the engines it is compatible with, providing a robust solution for maintaining the integrity of the engine’s electrical system.

K19 Engine Series

The K19 engine series is one of the prominent engine models that the Cummins Wiring Harness 3067880 is compatible with. This series is known for its durability and efficiency, making it a popular choice in various industrial and commercial applications. The wiring harness is meticulously designed to fit the K19 engine, ensuring that all electrical connections are secure and reliable. This compatibility is crucial for maintaining the engine’s performance and longevity, as it ensures that the electrical system operates without interruptions or failures.

Grouping of Compatible Engines

The Cummins Wiring Harness 3067880 is not limited to the K19 engine series alone. It is also compatible with other engine models that share similar electrical architecture and requirements. By grouping these engines together, the wiring harness provides a standardized solution for multiple engine types, simplifying maintenance and repair processes. This compatibility ensures that the wiring harness can be used across different engine models, reducing the need for multiple parts and simplifying inventory management for technicians and fleet operators.

Integration and Installation

The installation of the Cummins Wiring Harness 3067880 is straightforward, thanks to its precise design and compatibility with multiple engine models. Technicians can easily integrate this wiring harness into the engine’s electrical system, ensuring that all connections are secure and properly aligned. This ease of installation is a significant advantage, as it reduces downtime and allows for quicker repairs and maintenance. The wiring harness is also designed to withstand the harsh conditions often encountered in industrial and commercial environments, ensuring long-term reliability and performance.

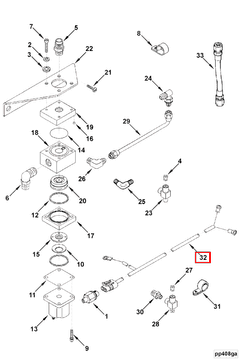

Role of Part 3067880 Wiring Harness in Engine Systems

The Part 3067880 Wiring Harness is integral to the efficient operation of various engine components. It facilitates the electrical connections necessary for the proper functioning of the injector, ensuring precise fuel delivery to the combustion chamber. This harness also interfaces with the Oil Control Valve (OCV), allowing for dynamic adjustments to oil flow, which is essential for maintaining optimal engine performance and longevity.

In the realm of performance parts, the wiring harness plays a significant role by providing the necessary electrical pathways for advanced engine management systems. It ensures that all performance-related components receive the correct signals and power, enhancing overall engine responsiveness and efficiency.

Furthermore, the harness is connected to the Valve Timing Control (VTC) system, enabling it to adjust valve timing in real-time. This capability is vital for maximizing engine performance across a wide range of operating conditions, from idle to high-speed operation.

Overall, the Part 3067880 Wiring Harness is a foundational component that supports the intricate electrical needs of modern engine systems, ensuring that all interconnected parts operate in harmony to deliver peak performance.

Conclusion

The 3067880 Wiring Harness by Cummins is a vital component in the electrical systems of commercial trucks and heavy-duty engines. Its robust design, compatibility with various engine models, and role in facilitating efficient electrical connections make it an indispensable part for maintaining the performance and reliability of these vehicles. Regular maintenance, proper installation, and adherence to safety precautions are essential for maximizing the lifespan and effectiveness of this part.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Lejda, Kazimierz and Wos, Pawel. Internal Combustion Engines. InTech, 2012.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.