This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

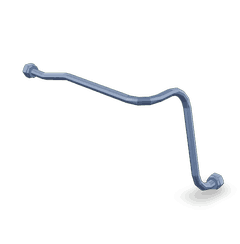

The Compressor Water Outlet Tube, identified by part number 3067536, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the engine cooling system of heavy-duty trucks, ensuring efficient operation and longevity of the engine 1.

Function and Operation

The Compressor Water Outlet Tube operates within the engine cooling system by directing the flow of coolant from the compressor to other parts of the engine. This directed flow helps in dissipating heat generated during engine operation, maintaining a stable operating temperature. The tube is designed to handle the pressures and temperatures typical in heavy-duty truck engines, ensuring consistent coolant distribution 2.

Purpose of the Compressor Water Outlet Tube

In the operation of a truck, the Compressor Water Outlet Tube plays a specific role by contributing to the maintenance of optimal engine temperature. By efficiently routing coolant, it aids in preventing overheating, which can lead to engine damage. This component is vital for the sustained performance and reliability of the engine under various operating conditions.

Key Features

The primary characteristics of the Compressor Water Outlet Tube include its material composition, typically a durable metal alloy that resists corrosion and withstands high temperatures. The design elements of the tube are tailored to fit precisely within the engine’s cooling system, ensuring a secure and leak-free connection. Unique attributes such as reinforced joints and a smooth interior surface enhance its performance by facilitating unimpeded coolant flow.

Benefits

The advantages provided by the Compressor Water Outlet Tube include improved engine efficiency through effective heat management. Its robust construction contributes to the longevity of the engine cooling system, reducing the likelihood of failures. Additionally, the reliability of this component ensures consistent engine performance, which is crucial for the operational demands of heavy-duty trucks.

Installation Process

Installing the Compressor Water Outlet Tube requires careful attention to detail. The process involves disconnecting the old tube, ensuring the mating surfaces are clean and free of debris, and then securely attaching the new tube. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the tube or its connections.

Common Issues and Troubleshooting

Typical problems associated with the Compressor Water Outlet Tube may include leaks due to worn seals or corrosion, and blockages from coolant contaminants. Troubleshooting methods involve inspecting the tube and connections for signs of wear or damage, and flushing the cooling system to remove any debris that may be obstructing coolant flow. Solutions may range from simple repairs, such as replacing seals, to more complex interventions like system flushing or tube replacement.

Maintenance Tips

To ensure the longevity and optimal performance of the Compressor Water Outlet Tube, routine maintenance practices are recommended. These include regular inspections for signs of wear or corrosion, ensuring connections are tight and secure, and maintaining the cooling system with the appropriate type and quality of coolant. Adhering to the manufacturer’s maintenance schedule can help prevent issues and extend the service life of the component.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of innovation and quality in engine technology. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, catering to various sectors such as transportation, construction, and power generation. Cummins’ reputation for durability, performance, and reliability makes it a preferred choice among professionals in the heavy-duty truck industry.

Role of Part 3067536 Compressor Water Outlet Tube in Engine Systems

The 3067536 Compressor Water Outlet Tube is an integral component in the efficient operation of the compressor coolant arrangement. This tube facilitates the directed flow of coolant from the compressor to other parts of the engine system, ensuring that the compressor remains within optimal operating temperatures.

In conjunction with the cylinder block, the Compressor Water Outlet Tube plays a significant role in maintaining the thermal balance of the engine. The cylinder block, being the structural core of the engine, houses the cylinders where combustion occurs. Efficient coolant flow, managed by the tube, helps in dissipating heat away from the cylinder block, preventing overheating and potential damage to the engine’s internal components.

Furthermore, the tube is closely associated with the cylinder block plumbing. This plumbing system is responsible for the circulation of coolant throughout the engine. The Compressor Water Outlet Tube ensures that the coolant exiting the compressor is efficiently routed through the cylinder block plumbing, enhancing the overall cooling efficiency of the engine. This integration is essential for maintaining the durability and performance of the engine under various operating conditions.

Conclusion

The Compressor Water Outlet Tube, part number 3067536, is a critical component in the engine cooling system of heavy-duty trucks. Its role in managing coolant flow and maintaining optimal engine temperature is essential for the efficient operation and longevity of the engine. Regular maintenance and adherence to manufacturer guidelines are recommended to ensure the continued performance and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.