This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

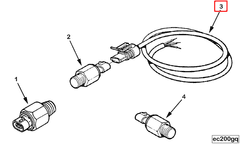

The Cummins 3066831 Wiring Harness is a specialized component designed for heavy-duty trucks. It plays a significant role in the electrical system by facilitating the connection between various electrical components. This harness ensures that electrical signals and power are efficiently distributed throughout the vehicle, contributing to the overall functionality and performance of the truck.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals to different parts of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring reliable performance. Within a vehicle’s electrical system, the wiring harness provides a structured pathway for electricity to flow from the power source to the components that require it 1.

Purpose of the 3066831 Wiring Harness

The Cummins 3066831 Wiring Harness is engineered to connect various electrical components within a heavy-duty truck. Its primary function is to ensure that electrical signals and power are correctly routed to the necessary parts of the vehicle. This includes connections to sensors, control modules, lights, and other electrical systems, thereby maintaining the integrity and efficiency of the electrical system.

Key Features

The Cummins 3066831 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and environmental factors. The harness is constructed with precision to ensure a secure fit and reliable connections. Additionally, it may include unique characteristics such as integrated protective coatings or specialized connectors that further contribute to its functionality.

Benefits

Utilizing the Cummins 3066831 Wiring Harness offers several advantages. It contributes to improved reliability by ensuring that electrical connections are secure and consistent. This enhances the efficiency of the electrical system, leading to better overall performance of the truck. Moreover, the harness plays a role in safety by reducing the risk of electrical faults and ensuring that all components receive the correct voltage and signals 2.

Installation Process

Installing the Cummins 3066831 Wiring Harness involves several steps to ensure proper integration into the truck’s electrical system. Begin by identifying the correct location for the harness within the vehicle. Carefully route the wires to avoid interference with other components and secure them in place using appropriate fasteners. Connect the harness to the power source and the various electrical components, ensuring that all connections are tight and secure. Finally, test the system to confirm that all connections are functioning correctly.

Troubleshooting Common Issues

Common issues with wiring harnesses may include loose connections, damaged wires, or faulty components. To troubleshoot these problems, begin by inspecting the harness for any visible signs of damage or wear. Check all connections to ensure they are secure and free from corrosion. If a specific component is not functioning, trace the wiring back to identify any breaks or shorts. Repair or replace any damaged sections as necessary to restore the harness’s functionality.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3066831 Wiring Harness, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, damage, or corrosion. Clean the harness and its connections to remove any dirt or debris that may affect performance. Additionally, ensure that all connections remain tight and secure. Following these maintenance routines will help prevent issues and ensure the harness continues to function reliably.

Safety Considerations

When working with the Cummins 3066831 Wiring Harness, it is important to observe several safety protocols. Ensure that the vehicle’s power source is disconnected before beginning any work to prevent electrical shocks. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer guidelines and safety standards to ensure a safe working environment and to prevent accidents.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong presence in the automotive industry, Cummins is committed to producing high-quality components that meet the demanding requirements of heavy-duty applications. The company’s dedication to innovation and excellence has established it as a trusted name in the production of automotive and industrial components.

Role of Part 3066831 Wiring Harness in Engine Systems

The part 3066831 Wiring Harness is an integral component in the electrical architecture of engine systems, specifically designed to interface with the Safety Controls Assembly. This wiring harness facilitates the transmission of electrical signals and power between various engine components and the safety controls, ensuring seamless operation and communication.

Integration with Safety Controls Assembly

The wiring harness connects to the Safety Controls Assembly, which is responsible for monitoring and regulating the operational parameters of the engine. It ensures that all safety protocols are adhered to, preventing any potential hazards during engine operation. The harness provides the necessary electrical connections for sensors, switches, and other safety-related components within the assembly.

Electrical Signal Transmission

One of the primary functions of the wiring harness is to transmit electrical signals from the safety controls to the engine’s electronic control unit (ECU). This allows the ECU to make real-time adjustments based on the data received, enhancing the engine’s performance and safety. The harness also enables the ECU to send commands back to the safety controls, creating a bidirectional communication pathway.

Power Distribution

In addition to signal transmission, the wiring harness is responsible for distributing power to various components within the safety controls assembly. This includes powering sensors, actuators, and other electronic devices that are essential for the engine’s safe and efficient operation. The harness ensures that each component receives the correct voltage and current, preventing any electrical malfunctions.

Sensor Connectivity

The wiring harness plays a significant role in connecting various sensors to the safety controls assembly. These sensors monitor parameters such as temperature, pressure, and engine speed, providing vital data that the safety controls use to make decisions. The harness ensures that these sensors are accurately and reliably connected, allowing for precise monitoring and control.

Switch and Relay Integration

The harness also integrates switches and relays within the safety controls assembly. These components are used to control the flow of electricity to different parts of the engine, enabling the safety controls to engage or disengage certain functions as needed. The wiring harness ensures that these switches and relays operate correctly, contributing to the overall safety and functionality of the engine system.

Grounding and Shielding

To ensure the integrity of the electrical signals and protect against electromagnetic interference, the wiring harness incorporates grounding and shielding mechanisms. This helps maintain a stable electrical environment within the engine system, reducing the risk of signal corruption and ensuring reliable operation of the safety controls assembly.

Conclusion

In summary, the part 3066831 Wiring Harness is a vital component that enables the safe and efficient operation of engine systems by providing essential electrical connections, signal transmission, power distribution, and protection mechanisms. Regular maintenance and adherence to safety protocols are crucial to ensure the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.