This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

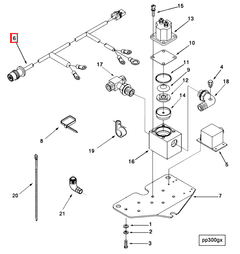

The Cummins 3066159 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. The significance of this wiring harness lies in its ability to ensure reliable and efficient electrical performance, which is essential for the overall operation and safety of the truck 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different parts of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in distributing power from the battery to various electrical components and in transmitting signals between the components and the vehicle’s control systems 2.

Purpose of the 3066159 Wiring Harness

The Cummins 3066159 Wiring Harness is specifically designed to integrate with the electrical system of a truck, connecting key components such as sensors, actuators, and control modules. It facilitates the transmission of power and signals necessary for the operation of these components, ensuring that the truck’s electrical systems function correctly. This wiring harness is engineered to work in conjunction with other electrical components and systems, contributing to the overall efficiency and reliability of the truck’s operations 3.

Key Features

The Cummins 3066159 Wiring Harness is characterized by its robust design and the use of high-quality materials. It features durable insulation to protect the wires from abrasion and environmental conditions, ensuring long-lasting performance. The harness is also designed with precision to fit snugly within the truck’s chassis, minimizing the risk of damage from movement or external forces. Additionally, it incorporates advanced connector technology to ensure secure and reliable connections between components 4.

Benefits of Using the 3066159 Wiring Harness

Utilizing the Cummins 3066159 Wiring Harness offers several advantages. It enhances the reliability of the truck’s electrical system by providing secure and durable connections. The efficient design of the harness contributes to the overall performance of the truck, ensuring that electrical components receive the power and signals they need to operate correctly. Furthermore, the use of high-quality materials and advanced design features contributes to the safety of the truck’s operations by reducing the risk of electrical failures 1.

Installation Considerations

When installing the Cummins 3066159 Wiring Harness, it is important to follow guidelines and best practices to ensure a successful outcome. Preparatory steps include ensuring the truck’s electrical system is powered down and disconnected from the battery to prevent electrical shocks or short circuits. The use of appropriate tools, such as wire strippers and crimping tools, is necessary for a secure installation. Common pitfalls to avoid include improper routing of the harness, which can lead to damage from abrasion or heat, and insufficient securing of the harness, which can result in movement and potential damage 2.

Troubleshooting Common Issues

Common problems with the Cummins 3066159 Wiring Harness may include loose connections, damaged wires, or faulty connectors. Diagnostic steps to identify these issues involve visually inspecting the harness for signs of wear or damage and testing the electrical connections for continuity and proper function. Solutions may range from tightening or replacing connectors to repairing or replacing damaged sections of the harness 3.

Maintenance Tips

Regular maintenance of the Cummins 3066159 Wiring Harness is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, damage, or corrosion, and cleaning the harness to remove dirt and debris that could affect its performance. Care should be taken to avoid exposing the harness to excessive heat, moisture, or physical stress, which can degrade its condition over time 4.

Safety Precautions

When working with the Cummins 3066159 Wiring Harness, it is important to observe electrical safety practices. This includes ensuring the truck’s electrical system is powered down before beginning any work to prevent electrical shocks. Handling the harness with care to avoid damaging the wires or connectors is also crucial. Additionally, using insulated tools and wearing protective gear can further enhance safety during installation or maintenance procedures 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of commercial vehicles, contributing to the efficiency, performance, and safety of these machines 2.

Cummins Wiring Harness 3066159 Compatibility with Cummins Engines

The Cummins Wiring Harness part number 3066159 is a critical component designed to ensure seamless electrical connectivity within various Cummins engine models. This wiring harness is engineered to interface with multiple engine types, ensuring that electrical signals are transmitted efficiently and reliably 3.

V903 Engine Series

The V903 engine series, known for its robust performance and reliability, is one of the key beneficiaries of the 3066159 wiring harness. This harness is specifically tailored to fit the V903 engines, providing a precise and secure connection to the engine’s electrical system. The design ensures that all necessary electrical components are properly linked, facilitating optimal engine operation and performance 4.

Integration with Cummins Engines

The 3066159 wiring harness is meticulously crafted to integrate with various Cummins engine models, ensuring compatibility and ease of installation. Its design allows for straightforward integration with the engine’s electrical architecture, minimizing the risk of errors during installation and ensuring that all electrical pathways are correctly established 1.

Ensuring Reliable Performance

By using the 3066159 wiring harness, engine operators can expect reliable and consistent performance. The harness is built to withstand the rigors of engine operation, providing a durable and long-lasting solution for electrical connectivity. This reliability is crucial for maintaining the overall health and efficiency of the engine, reducing the likelihood of electrical faults and downtime 2.

Precision Engineering

The precision engineering behind the 3066159 wiring harness ensures that it fits snugly and securely within the engine’s electrical system. This precision is achieved through rigorous testing and quality control measures, guaranteeing that the harness meets the highest standards of performance and reliability. The result is a seamless integration that enhances the engine’s operational efficiency and longevity 3.

Role of Part 3066159 Wiring Harness in Engine Systems

The 3066159 Wiring Harness is an integral component in the electrical system of engine assemblies, facilitating the connection between various electrical components and the engine’s control unit. This harness ensures seamless communication and power distribution among parts such as sensors, actuators, and the engine control module (ECM) 4.

In the context of performance parts, the 3066159 Wiring Harness plays a significant role by providing the necessary electrical pathways for high-performance components. It ensures that these parts receive the correct voltage and signals to operate efficiently, contributing to the overall performance of the engine 1.

For step control systems, which are used to manage the sequential operation of engine components, the wiring harness is essential. It allows for precise timing and coordination of electrical signals, ensuring that each step in the control sequence is executed accurately. This is particularly important in engines with complex control systems, where timing can significantly affect performance and efficiency 2.

The harness also supports the integration of various sensors within the engine system. Sensors such as the oxygen sensor, throttle position sensor, and crankshaft position sensor rely on the wiring harness to transmit data to the ECM. This data is vital for the ECM to make real-time adjustments to the engine’s operation, optimizing performance and fuel efficiency 3.

Additionally, the 3066159 Wiring Harness is responsible for powering actuators such as fuel injectors, ignition coils, and variable valve timing solenoids. These components require a stable and consistent electrical supply to function correctly, and the wiring harness ensures that they receive the necessary power and control signals from the ECM 4.

In summary, the 3066159 Wiring Harness is a fundamental component in the electrical architecture of engine systems. It enables the efficient operation of performance parts, ensures the accurate execution of step control sequences, and facilitates the communication between sensors, actuators, and the engine control module.

Conclusion

The Cummins 3066159 Wiring Harness is a critical component in the electrical systems of commercial trucks and Cummins engines. Its robust design, high-quality materials, and precision engineering ensure reliable and efficient electrical performance. By facilitating secure and durable connections between electrical components, this part contributes to the overall safety, performance, and reliability of the vehicle. Regular maintenance and adherence to safety precautions are essential to maximize the longevity and effectiveness of the wiring harness.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ ↩ ↩ ↩ ↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ ↩ ↩ ↩ ↩ -

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ ↩ ↩ ↩ ↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.