This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

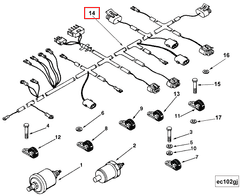

The Cummins 3062865 Wiring Harness is a specialized component designed for use in commercial trucks. It plays a role in the vehicle’s electrical system by facilitating the connection between various electrical components and the truck’s power source. This part ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, along with connectors that allow for easy integration with other parts of the electrical system. The primary function of a wiring harness is to organize and protect the wires, reducing the risk of damage and ensuring reliable electrical connections 1.

Purpose of the Cummins 3062865 Wiring Harness

This Cummins part is specifically designed to play a role in the electrical system of commercial trucks by providing a structured and protected pathway for electrical signals and power. It connects various electrical components such as sensors, control modules, and actuators to the truck’s battery and other power sources. This harness ensures that all electrical components receive the necessary power and signals to function correctly, contributing to the truck’s overall performance and reliability.

Key Features

The 3062865 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable insulated wires that are resistant to abrasion, corrosion, and extreme temperatures. The harness also features precision-engineered connectors that ensure secure and reliable connections. Additionally, its design allows for flexibility and ease of installation, while its compact form factor helps to save space within the truck’s engine compartment.

Benefits of Using the Cummins 3062865 Wiring Harness

Utilizing this part offers several advantages. It enhances the efficiency of the electrical system by providing an organized and protected pathway for electrical signals and power. This results in improved reliability and performance of the truck’s electrical components. Additionally, the harness contributes to the safety of the vehicle by reducing the risk of electrical faults and ensuring that all components operate within their specified parameters.

Installation Considerations

When installing the 3062865 Wiring Harness, it is important to follow guidelines and best practices to ensure a successful integration into the truck’s electrical system. Preparatory steps may include disconnecting the battery to prevent electrical shocks and ensuring that the engine compartment is clean and free of debris. The use of appropriate tools, such as wire strippers and crimping tools, is recommended to facilitate a secure and reliable installation.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 3062865 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear, corrosion, or damage, and addressing any issues promptly. Common problems may include loose connections or damaged wires, which can be resolved by tightening connectors or replacing affected sections of the harness. Adhering to a maintenance schedule helps to prevent electrical faults and ensures the continued reliability of the truck’s electrical system.

Safety Precautions

When working with the 3062865 Wiring Harness, it is important to observe electrical safety practices. This includes disconnecting the battery before beginning any work to prevent electrical shocks. Additionally, using insulated tools and wearing protective gear, such as gloves and safety glasses, can help to protect against potential hazards. Handling the wiring harness with care and avoiding sharp edges or excessive force during installation or maintenance is also recommended.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry. The company is committed to innovation and sustainability, offering a wide range of products and services that meet the evolving needs of its customers 2.

Role of Part 3062865 Wiring Harness in Engine Systems

The 3062865 wiring harness is an integral component in the orchestration of various engine systems. It serves as the vital conduit for electrical signals and power distribution among the engine’s electronic control units (ECUs), sensors, and actuators.

Integration with Engine Components

-

Harness and Wiring: The wiring harness is meticulously designed to route electrical connections from the battery to the engine control module (ECM), ensuring a stable and efficient power supply. It also facilitates communication between the ECM and various engine sensors, such as the oxygen sensor, mass airflow sensor, and throttle position sensor. This allows for precise monitoring and adjustment of engine performance parameters 3.

-

Panel: Within the engine compartment, the wiring harness interfaces with the fuse panel and relay panel. These panels house the protective devices and switching components that safeguard the electrical circuits from overloads and short circuits. The harness ensures that power is correctly distributed to these panels, enabling them to perform their protective functions effectively.

-

Engine Instrument: The wiring harness plays a key role in connecting the engine’s instrumentation systems. It links the engine’s sensors to the vehicle’s dashboard instruments, such as the tachometer, speedometer, and various warning lights. This connection allows for real-time monitoring of engine performance and alerts the driver to any anomalies or malfunctions.

Conclusion

In summary, the 3062865 wiring harness is essential for the seamless operation of the engine’s electrical systems. It ensures that power and data are efficiently transmitted between the various components, contributing to the overall reliability and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.