This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

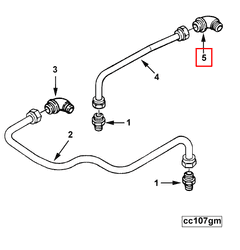

The Compressor Water Outlet Tube, identified by part number 3061378 and manufactured by Cummins, is a critical component in the cooling systems of heavy-duty trucks. This tube facilitates the efficient operation of truck engines by managing the flow of coolant. Cummins, a renowned name in the automotive industry, ensures that this component meets the rigorous demands of heavy-duty applications, contributing to the overall functionality and reliability of truck engines 1.

Function and Operation

The Compressor Water Outlet Tube operates within the engine cooling system by directing the flow of coolant from the compressor to various parts of the engine. This process is vital for maintaining optimal engine temperatures, as it ensures that the coolant circulates effectively, absorbing heat from the engine components and dissipating it through the cooling system 2.

Key Features

The design and material characteristics of the Compressor Water Outlet Tube are tailored to enhance its performance and durability. Constructed from high-quality materials, the tube is resistant to corrosion and capable of withstanding the high pressures and temperatures typical of heavy-duty engine environments. Its precise engineering ensures a secure fit and efficient coolant flow, contributing to the tube’s reliability and longevity 3.

Benefits

The Compressor Water Outlet Tube offers several advantages, including improved engine cooling efficiency. By ensuring a consistent and directed flow of coolant, it helps reduce the risk of engine overheating. This, in turn, contributes to enhanced overall engine performance, as optimal cooling is crucial for maintaining engine efficiency and preventing damage.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for its effective operation. It is designed to integrate seamlessly with specific engine models, ensuring compatibility and efficient performance. Detailed guidelines for installation are provided to facilitate correct placement and connection within the engine system.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and effectiveness of the Compressor Water Outlet Tube. Regular inspections for signs of wear, leaks, or corrosion can help identify potential issues before they lead to more significant problems. Common issues may include blockages or leaks, which can often be resolved through cleaning or replacement of the tube.

Performance Impact

The Compressor Water Outlet Tube plays a role in the engine’s performance by contributing to the maintenance of optimal operating temperatures. Efficient coolant flow facilitated by the tube helps prevent engine damage due to overheating, ensuring that the engine operates within its designed parameters for efficiency and durability.

Cummins: Manufacturer Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s commitment to excellence is evident in its wide range of products, including engine components that are engineered to meet the demanding requirements of heavy-duty applications.

Compressor Water Outlet Tube (Part 3061378) Compatibility with Cummins Engines

The Compressor Water Outlet Tube, part number 3061378, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is integral to the engine’s cooling system, ensuring efficient water flow and temperature regulation.

N14 CELECT and N14 CELECT PLUS Engines

The Compressor Water Outlet Tube is compatible with both the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The part’s design ensures that it fits perfectly within the engine’s architecture, facilitating optimal water flow from the compressor section to the cooling system.

N14 MECHANICAL Engine

Similarly, the N14 MECHANICAL engine also accommodates the Compressor Water Outlet Tube. This engine variant is recognized for its mechanical simplicity and durability, making it a popular choice in various industrial applications. The part’s integration into the N14 MECHANICAL engine is straightforward, ensuring that it performs its function effectively without requiring any modifications.

Grouping of Engines

When considering the compatibility of the Compressor Water Outlet Tube with the listed engines, it is evident that the part is designed to fit within the N14 series engines. This includes the N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL variants. The commonality in design and function across these engines ensures that the part can be used interchangeably, providing a standardized solution for maintaining the engine’s cooling system.

Role of Part 3061378 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube, identified by part number 3061378, is integral to the efficient operation of various engine systems. Its primary function is to facilitate the flow of coolant from the compressor to other parts of the engine, ensuring optimal temperature regulation and performance.

Integration with Compressor Coolant System

In the compressor coolant system, the 3061378 tube acts as a conduit for coolant, directing it from the compressor to the cooling circuit. This ensures that the compressor remains at an optimal operating temperature, preventing overheating and potential damage. The tube’s precise arrangement within the system allows for seamless integration with other components, enhancing the overall efficiency of the coolant flow.

Connection to Mounting Tube and Plumbing

The Compressor Water Outlet Tube is typically connected to a mounting tube, which secures it in place and ensures a stable connection within the engine’s plumbing system. This connection is vital for maintaining the integrity of the coolant pathway, preventing leaks, and ensuring consistent coolant distribution. The tube’s design allows for easy integration with existing plumbing, making it a reliable component in the engine’s cooling infrastructure.

Role in Water Drain Tube System

Additionally, the 3061378 tube plays a role in the water drain tube system by facilitating the removal of any excess water or condensation that may accumulate within the compressor. This helps in maintaining the compressor’s efficiency and longevity by preventing water buildup, which could lead to corrosion or reduced performance.

Overall Contribution to Engine Performance

By ensuring efficient coolant flow and proper drainage, the Compressor Water Outlet Tube contributes significantly to the engine’s overall performance. Its integration with the compressor coolant system, mounting tube, and plumbing ensures that the engine operates within safe temperature ranges, enhancing reliability and durability.

Conclusion

The Compressor Water Outlet Tube, part number 3061378, manufactured by Cummins, is a vital component in the cooling systems of heavy-duty trucks. Its role in facilitating efficient coolant flow and temperature regulation is crucial for maintaining engine performance and reliability. Proper installation, maintenance, and understanding of its compatibility with various engine models are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.