This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Spring Part #3060614 is a component designed for use in the fuel injection systems of heavy-duty trucks. Its purpose is to ensure the proper functioning of the fuel injector by maintaining the necessary pressure and timing for fuel delivery. This part contributes to the efficient operation of diesel engines by facilitating precise fuel atomization and delivery, which are vital for engine performance and fuel efficiency 2.

Basic Concepts of Injector Springs

Injector springs are components within fuel injection systems that help control the opening and closing of the injector nozzle. They work by applying force to keep the nozzle closed until the appropriate pressure is reached, at which point the nozzle opens to release fuel into the combustion chamber. The performance of diesel engines is significantly influenced by the efficiency of the fuel injection process, making injector springs a key element in achieving optimal engine operation 1.

Role of the Injector Spring in Truck Operation

The 3060614 Injector Spring plays a specific role in the fuel injection process by interacting with the injector nozzle and the fuel delivery system. When the fuel pressure increases to a predetermined level, the spring allows the nozzle to open, releasing a fine spray of fuel into the combustion chamber. This precise timing and pressure control are crucial for efficient combustion, which in turn affects the engine’s power output and fuel efficiency. The spring’s ability to withstand high pressures and temperatures ensures reliable operation under various driving conditions 2.

Key Features of the 3060614 Injector Spring

The design and construction of the 3060614 Injector Spring incorporate several features that enhance its performance and durability. Constructed from high-quality materials, the spring is engineered to withstand the extreme conditions within a diesel engine. Its spring tension is calibrated to provide the necessary force for optimal injector operation. Additionally, the spring’s design may include features such as corrosion resistance and fatigue resistance, which contribute to its longevity and reliability in heavy-duty applications 2.

Benefits of Using the 3060614 Injector Spring

Utilizing the 3060614 Injector Spring offers several advantages for diesel engine performance. Improved fuel atomization leads to more efficient combustion, which can result in better fuel economy and reduced emissions. Consistent fuel delivery ensures that the engine operates smoothly and reliably, contributing to overall engine efficiency and power output. The enhanced performance and durability of the 3060614 Injector Spring make it a valuable component for maintaining the high standards of heavy-duty truck engines 2.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the 3060614 Injector Spring, it is important to be aware of common issues and perform regular maintenance. Symptoms of injector spring failure may include poor engine performance, increased fuel consumption, or irregular idling. Diagnostic procedures should involve checking the spring for signs of wear, corrosion, or damage. Maintenance practices include regular inspection of the injector system, cleaning components to remove deposits, and replacing the spring as necessary to prevent failure and ensure efficient engine operation 1.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to advancing technology and meeting the needs of its customers is evident in its diverse product range and continuous investment in research and development 2.

Role of Part 3060614 Injector Spring in Engine Systems

The injector spring, identified by part number 3060614, is a critical component in the orchestration of fuel delivery within an engine system. Its primary function is to maintain the precise operation of the injector, ensuring that fuel is delivered at the correct pressure and timing. This is particularly important in high-performance engines where the margin for error is minimal 2.

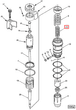

Interaction with the Cylinder Head and Camshaft

The injector spring works in conjunction with the cylinder head and camshaft to optimize engine performance. As the camshaft rotates, it actuates the valve train, which in turn controls the intake and exhaust of air and fuel. The injector spring ensures that the injector responds accurately to these movements, delivering fuel in a manner that is synchronized with the valve events. This synchronization is vital for maintaining efficient combustion and maximizing engine output 2.

Integration with the Oil Manifold

In engines equipped with an oil manifold, the injector spring plays a role in the hydraulic actuation of the injectors. The oil manifold supplies pressurized oil to the injectors, and the spring helps to regulate the force applied to the injector plunger. This regulation is key to achieving the desired fuel spray pattern and atomization, which are critical for combustion efficiency and emissions control 2.

Contribution to Overall Engine Performance

The performance of an engine is heavily influenced by the precision of its fuel delivery system. The injector spring, as part of this system, contributes to the engine’s ability to operate smoothly and efficiently across a range of conditions. By ensuring that the injector operates within its designed parameters, the spring helps to maintain consistent engine performance, whether the engine is idling, cruising, or under full load 2.

Importance in Performance Parts

For those working with performance parts, understanding the role of the injector spring is fundamental. Upgrading to high-flow injectors or modifying the fuel system requires careful consideration of the spring’s characteristics. A spring that is too weak may not provide sufficient force to overcome the increased fuel flow, while one that is too strong could lead to over-fueling or other performance issues. Therefore, selecting the appropriate injector spring is a key aspect of tuning and modifying engine systems for enhanced performance 2.

Conclusion

The Cummins Injector Spring Part #3060614 is a vital component in the fuel injection systems of heavy-duty trucks. Its role in maintaining the necessary pressure and timing for fuel delivery ensures efficient engine operation, contributing to better performance and fuel efficiency. Regular maintenance and understanding its interaction with other engine components are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.