This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3058469 Push Rod is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s valve train mechanism, contributing to the overall operation and performance of the engine. Understanding its purpose and role is fundamental for maintaining and optimizing the engine’s efficiency and reliability.

Basic Concepts of Push Rods

A push rod is a cylindrical component that transmits motion from the camshaft to the valve train in an engine. It operates by converting the rotational motion of the camshaft into linear motion, which is then used to open and close the engine’s valves at precise intervals. This mechanism is crucial for the engine’s ability to intake air and fuel and expel exhaust gases, directly influencing the engine’s performance and efficiency 1.

Purpose and Function of the 3058469 Push Rod

The Cummins 3058469 Push Rod plays a role in the engine’s operation by facilitating the transfer of motion from the camshaft to the rocker arms, which in turn operate the engine valves. This push rod is engineered to withstand the high stresses and temperatures within the engine compartment, ensuring reliable valve operation under various operating conditions. Its design allows for efficient transmission of motion, contributing to the engine’s overall performance 2.

Key Features

The Cummins 3058469 Push Rod is characterized by its robust material composition and precise design elements. It is manufactured using high-quality materials that offer superior resistance to wear and fatigue. The push rod’s design includes features that enhance its performance and durability, such as a smooth surface finish to reduce friction and precise dimensions to ensure accurate valve operation 3.

Benefits of Using the 3058469 Push Rod

Utilizing the Cummins 3058469 Push Rod in an engine setup can lead to several advantages. These include improved engine efficiency due to its precise operation, enhanced reliability under demanding conditions, and increased longevity thanks to its durable construction. Compared to other push rod options, the 3058469 model is designed to offer superior performance and durability, contributing to the engine’s overall effectiveness 4.

Installation and Maintenance

Proper installation of the Cummins 3058469 Push Rod is vital for ensuring optimal engine performance. It is recommended to follow manufacturer guidelines for installation procedures and to use the appropriate tools to avoid damage. Regular maintenance, including inspection for wear and proper lubrication, is essential to maintain the push rod’s performance and extend its service life. Adhering to these practices helps ensure the engine operates efficiently and reliably.

Troubleshooting Common Issues

Common issues associated with push rods, such as wear, breakage, or improper installation, can affect engine performance. Identifying these problems early is important for maintaining engine efficiency. Troubleshooting steps may include inspecting the push rod for signs of wear or damage, ensuring it is properly installed, and checking for any obstructions or misalignments in the valve train mechanism. Addressing these issues promptly can help prevent more significant engine problems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 3058469 Push Rod, which is designed to meet the high demands of heavy-duty applications.

Push Rod 3058469 Compatibility with Cummins Engines

The Push Rod part number 3058469, manufactured by Cummins, is a critical component in ensuring the smooth operation of the valve train in certain Cummins engines. This part is designed to interface with the camshaft and valve train, facilitating the transfer of motion from the camshaft to the valves, which is essential for the engine’s intake and exhaust functions.

N14 CELECT and N14 MECHANICAL Engines

The Push Rod 3058469 is specifically engineered to fit seamlessly within the N14 CELECT and N14 MECHANICAL engines. Both of these engines are known for their robust design and reliability, making them a popular choice in various heavy-duty applications. The push rod’s precise dimensions and material properties ensure it can withstand the high stresses and temperatures inherent in these engines.

In the N14 CELECT engine, the push rod plays a crucial role in the electronic fuel injection system, where it must operate with high precision to maintain optimal engine performance. Similarly, in the N14 MECHANICAL engine, which relies on a mechanical fuel injection system, the push rod’s reliability is equally important for the engine’s longevity and efficiency.

Installation and Maintenance

When installing the Push Rod 3058469 in either the N14 CELECT or N14 MECHANICAL engines, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. Regular maintenance checks should be conducted to inspect for any signs of wear or damage, which could affect the engine’s performance. Cummins recommends using genuine parts for replacements to maintain the integrity and performance of the engine.

Role of Part 3058469 Push Rod in Engine Systems

The Part 3058469 Push Rod is an integral component in the operation of several engine systems, facilitating the transfer of motion from the camshaft to the valves. This motion is essential for the proper functioning of the engine’s intake and exhaust processes.

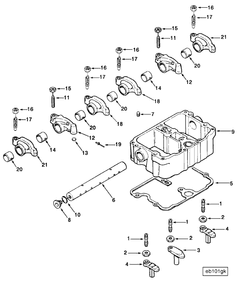

Interaction with Base Parts

In conjunction with base parts, the Push Rod ensures a stable and consistent transfer of force. The base parts provide the necessary mounting points and structural support for the Push Rod to operate effectively. This interaction is fundamental for maintaining the precision required in valve timing.

Coordination with EBM-Lever and EBM: Lever

The Push Rod works in tandem with the EBM-Lever (Electronic Brake Modulator Lever) and EBM: Lever to enhance the modulation of valve operation. These levers amplify the motion initiated by the Push Rod, allowing for finer control over valve opening and closing. This coordination is particularly important in engines requiring precise valve timing for optimal performance.

Integration with Rocker and Rocker-Lever Systems

When integrated with rocker and rocker-lever systems, the Push Rod plays a pivotal role in converting the rotational motion of the camshaft into linear motion for the valves. The rocker acts as a force multiplier, and the Push Rod transmits this amplified force to the valves. This setup ensures that the valves open and close with the necessary force and speed, contributing to efficient combustion and overall engine performance.

Functionality in Lever and Rocker Assemblies

In lever and rocker assemblies, the Push Rod serves as a critical link. It transmits the motion from the camshaft to the rocker arms, which then actuate the valves. This assembly is designed to handle the high stresses and dynamic loads encountered in engine operation, ensuring reliable and consistent valve actuation.

Role in Parts and Base Assemblies

Within parts and base assemblies, the Push Rod ensures that the mechanical linkage between the camshaft and valves remains intact. The base assembly provides the foundational structure, while the Push Rod delivers the necessary motion. This integration is essential for the durability and performance of the engine, as it ensures that all components work in harmony to achieve optimal engine operation.

Conclusion

The Cummins 3058469 Push Rod is a vital component in the valve train mechanism of heavy-duty engines, ensuring efficient and reliable operation. Its robust design, precise engineering, and compatibility with Cummins engines make it a critical part for maintaining engine performance and longevity. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential practices to maximize the benefits of this Cummins part.

-

Angelina Eret, Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves, Springer Nature, 2024.

↩ -

Department of Energy, Department of Energy Fundamentals Handbook, 2015.

↩ -

Konrad Reif Ed, Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Springer, 2014.

↩ -

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.