This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3056060 Rivet is a specialized component designed for use in commercial trucks. It serves a vital role in the construction and maintenance of these vehicles by providing a secure and durable method of joining materials. Rivets, in general, are fundamental in truck construction, ensuring the structural integrity and longevity of various components. This Cummins part is engineered to meet the demanding requirements of heavy-duty applications.

Basic Concepts of Rivets

A rivet is a permanent mechanical fastener that consists of a cylindrical shaft with a head on one end. It functions by being inserted into holes drilled through the materials to be joined and then deformed on the opposite end to create a second head, effectively clamping the materials together. Rivets are used across various industries due to their strength, simplicity, and reliability. There are several types of rivets, including solid, blind, and structural rivets, each suited to different applications based on the materials and loads they need to accommodate 1.

Purpose of the 3056060 Rivet in Truck Operation

This part plays a specific role in the operation and structural integrity of commercial trucks. It is utilized in areas where high strength and durability are required, such as in the frame, body panels, and other critical components. By providing a strong and permanent join, the rivet contributes to the overall performance and safety of the vehicle, ensuring that the truck can withstand the rigors of heavy-duty use.

Key Features of the 3056060 Rivet

The 3056060 Rivet is distinguished by several key features. It is composed of high-strength materials, typically steel or aluminum alloys, which offer excellent durability and resistance to wear and tear. The design of the rivet includes a robust shaft and precisely formed heads that ensure a secure fit. Additionally, the rivet may have unique attributes such as corrosion resistance coatings or specialized shapes to enhance its performance in specific applications.

Benefits of Using the 3056060 Rivet

Incorporating the 3056060 Rivet in truck construction offers several advantages. Its high strength and durability ensure that the joined materials remain securely fastened under heavy loads and harsh conditions. The rivet’s resistance to environmental factors, such as moisture and temperature fluctuations, further enhances its reliability. Additionally, the permanent nature of rivets eliminates the need for periodic tightening, reducing maintenance requirements 2.

Installation Process

Proper installation of the 3056060 Rivet is crucial to ensure a secure and lasting join. The process involves drilling precise holes through the materials to be joined, inserting the rivet, and then deforming the opposite end to create the second head. Tools required for installation include a drill, a rivet gun, and appropriate dies. Best practices include ensuring the holes are clean and free of debris, using the correct rivet size for the application, and applying even pressure during the riveting process to achieve a uniform and strong join.

Troubleshooting Common Issues

Typical problems that may arise with the 3056060 Rivet include loosening due to vibration or corrosion. To address loosening, it may be necessary to reinforce the joint with additional fasteners or use vibration-damping materials. Corrosion can be mitigated by applying protective coatings or using rivets made from corrosion-resistant materials. Regular inspection and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

Regular inspection and maintenance of the 3056060 Rivet are recommended to prolong its lifespan and ensure continued reliability. This includes checking for signs of corrosion, ensuring the rivet remains securely in place, and addressing any issues promptly. Additionally, protecting the rivet from environmental factors by applying coatings or sealants can enhance its durability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industries. The company offers a wide range of products designed to meet the needs of various applications, emphasizing quality, performance, and reliability. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name in the industry 3.

Compatibility of 3056060 Rivet with Various Engine Models

The 3056060 Rivet is compatible with several Cummins engine models, ensuring secure fastening in various engine applications. Below is a detailed overview of its compatibility:

K-Series Engines

- K19: Utilized to secure components requiring robust fastening.

- K38: Employed in areas where high-strength fastening is necessary.

- K50: Ensures critical parts are securely fastened.

M-Series Engines

- M11 MECHANICAL: Used for fastening various components, ensuring durability and reliability.

- N14 MECHANICAL: Employed in key areas where secure fastening is essential.

NH/NT Series Engines

- NH/NT 855: Utilizes the rivet to secure components, maintaining the engine’s structural integrity.

QSK Series Engines

- QSK19 CM500: Incorporates the rivet to ensure that critical parts are fastened securely, contributing to the engine’s overall performance and longevity.

V-Series Engines

- V28: Uses the rivet in areas requiring high-strength fastening to maintain structural integrity.

X-Series Engines

- X15 CM2450 X134B: Employs the rivet to secure various components, ensuring the engine’s reliability and performance.

Role of 3056060 Rivet in Engine Systems

The 3056060 Rivet is instrumental in securing various components within engine systems, ensuring both structural integrity and functional reliability.

Accessories

This rivet is used to fasten components such as the belt guard, which protects the engine’s belt drive system from external damage. It also plays a role in securing the wiring and harness assemblies, ensuring that electrical connections remain stable and protected from vibrations.

Connector Wiring Retainer

The 3056060 Rivet ensures that wiring connections are held firmly in place, preventing any potential disconnections that could lead to electrical faults.

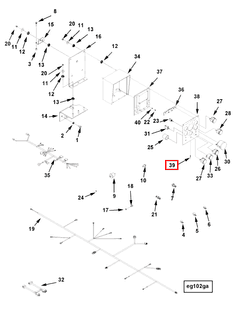

Engine Instrument Panel and Assembly

This rivet is employed to attach various gauges and indicators, ensuring they remain securely mounted and provide accurate readings.

Generator Control Panel

The rivet maintains the structural stability of the panel, which is essential for the safe operation of the generator.

Electronic Control Module Wiring

The rivet is used to secure connections, ensuring that the module operates within specified parameters.

Instrument Panel and Mounting

This rivet ensures that all components are securely attached, providing a stable platform for the display of vital engine information.

Instrument Panel/Enclosure Assembly and Panel Instrument

The 3056060 Rivet ensures that all elements are held together robustly, contributing to the overall durability and reliability of the engine system.

Conclusion

The Cummins 3056060 Rivet is a critical component in the assembly and maintenance of commercial trucks and various engine models. Its high strength, durability, and resistance to environmental factors make it an essential part in ensuring the structural integrity and functional reliability of engine systems. Proper installation, regular maintenance, and addressing common issues promptly are key to maximizing the performance and lifespan of this rivet.

-

Arthur J Caines, Roger F Haycock and John E Hillier, Automotive Lubricants Reference Book, SAE International, 2004.

↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

Sean Bennett, Ian Andrew Norman, Heavy Duty Truck Systems Fifth Edition, Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.