This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

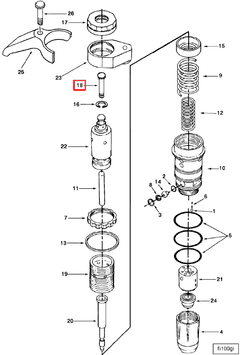

The Cummins Injector Plunger Link, part number 3054474, is a critical component in the fuel injection system of heavy-duty truck engines. Cummins, a leading manufacturer in the automotive industry, particularly for diesel engines and components, produces this part to enhance the efficiency and performance of truck engines. Understanding the role and function of this Cummins part is essential for maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts

Injector plunger links are fundamental components within the fuel injection system of diesel engines. They facilitate the precise control of fuel delivery to the engine’s combustion chambers. By connecting the injector plunger to the camshaft or other actuating mechanisms, these links ensure that fuel is injected at the correct moment and in the right quantity, which is crucial for engine performance and efficiency 1.

Purpose and Function

The Injector Plunger Link 3054474 plays a specific role in the operation of a truck’s engine. It connects the injector plunger to the camshaft, allowing for the timed injection of fuel into the engine’s cylinders. This precise timing is critical for efficient combustion, which in turn affects the engine’s power output, fuel efficiency, and emissions. The link works in conjunction with other components of the fuel injection system, such as the fuel pump and injectors, to ensure optimal engine performance 3.

Key Features

The Injector Plunger Link 3054474 is designed with several features that enhance its performance and durability. It is constructed from high-quality materials to withstand the high pressures and temperatures within the engine compartment. The design of the link ensures smooth operation and minimal wear, contributing to the longevity of the component. Additionally, its precise engineering allows for accurate fuel injection timing, which is essential for engine efficiency and performance 2.

Benefits

The use of the Injector Plunger Link 3054474 offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is injected into the engine at the optimal time. This precise timing enhances combustion efficiency, leading to better engine performance. Furthermore, the robust design and high-quality materials used in its construction ensure reliability, even under demanding operating conditions. This reliability is crucial for heavy-duty trucks, which often operate in challenging environments 4.

Troubleshooting and Maintenance

Common issues with the Injector Plunger Link 3054474 may include wear and tear, leading to inaccurate fuel injection timing. Regular inspection and maintenance are recommended to ensure optimal performance. Troubleshooting steps may involve checking for signs of wear, ensuring proper alignment with the camshaft, and verifying that the link operates smoothly without excessive friction. Maintenance practices should include cleaning the component and lubricating moving parts as necessary 3.

Installation and Replacement

Proper installation and replacement of the Injector Plunger Link 3054474 require attention to detail and adherence to safety precautions. The process involves disconnecting the link from the camshaft and injector plunger, followed by the installation of the new link. Necessary tools and equipment should be used to ensure a secure fit and proper alignment. Safety precautions, such as wearing protective gear and ensuring the engine is cool before beginning work, should be observed during the installation and replacement process 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, particularly for diesel engines and components, Cummins is committed to innovation, quality, and customer satisfaction. The company’s extensive product offerings and global presence make it a trusted name in the industry.

Cummins Injector Plunger Link (Part 3054474) Compatibility

The Cummins Injector Plunger Link, part number 3054474, is a critical component in the fuel injection system of various diesel engines. This part is designed to ensure the precise operation of the injectors, which is essential for maintaining optimal engine performance and efficiency.

N14 MECHANICAL

The N14 MECHANICAL engine is a robust and reliable power unit often found in heavy-duty applications. The Injector Plunger Link (3054474) in this engine is responsible for transferring the motion from the injector plunger to the injector body. This linkage ensures that the injectors open and close at the correct times, which is crucial for the proper atomization of fuel and efficient combustion. The precision of this component directly impacts the engine’s fuel efficiency and overall performance.

NH/NT 855

The NH/NT 855 engines are another series where the Injector Plunger Link (3054474) plays a vital role. These engines are known for their durability and power, often used in agricultural and construction equipment. The injector plunger link in these engines facilitates the movement of the injector plunger, ensuring that the fuel is injected into the combustion chamber at the precise moment required. This synchronization is essential for maintaining the engine’s power output and fuel economy.

Grouping Engines for Compatibility

Both the N14 MECHANICAL and NH/NT 855 engines utilize the Injector Plunger Link (3054474) in a similar manner, emphasizing the importance of this component in the fuel injection system. The design and functionality of the part are tailored to meet the specific requirements of these engines, ensuring reliable and efficient operation. The compatibility of this part across these engines highlights its versatility and critical role in the overall performance of the engine.

Role of Part 3054474 Injector Plunger Link in Engine Systems

The Injector Plunger Link, identified by part number 3054474, is an integral component in the synchronization and operation of several engine systems. It interfaces directly with the Injector and Injector Tappet, ensuring precise fuel delivery timing. This link is essential for the efficient operation of the Top Stop (Step) Injector and Top Stop Injector, allowing for accurate fuel metering and injection.

In conjunction with the Camshaft and Cam Follower Housing, the Injector Plunger Link facilitates the mechanical actuation required for fuel injection. It works in harmony with the Hydraulic Variable Timing Tappet to adjust injection timing based on engine load and speed, optimizing performance and efficiency.

The link also plays a significant role when paired with EBM: Injector and EBM: Performance Parts, enhancing the overall responsiveness and power output of the engine. It ensures that the Injector Plumbing operates under optimal conditions, preventing fuel leaks and ensuring consistent fuel pressure.

Furthermore, the Injector Plunger Link is vital during engine overhauls, often included in Overhaul Kits to guarantee that all components, including the Connecting Rod and Piston and Cylinder Head, function seamlessly post-repair. Its integration with Tachometer Parts Kit allows for precise monitoring of engine performance, providing valuable data for tuning and maintenance.

Conclusion

In summary, the Injector Plunger Link (part 3054474) is a key element in the intricate dance of engine components, ensuring that fuel injection is timed perfectly to maximize engine performance and reliability. Regular maintenance and proper installation are crucial to ensure the longevity and efficiency of this critical component.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ ↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.