This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

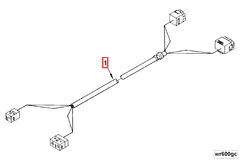

The Cummins 3053042 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a central conduit for electrical signals and power distribution within the vehicle, ensuring that various systems operate efficiently and reliably. The significance of this wiring harness in commercial truck operations lies in its ability to streamline electrical connections, reduce the risk of wiring errors, and enhance overall vehicle performance 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals to different parts of a vehicle. It consists of insulated wires bundled together, often secured with ties or conduits, and terminated with connectors for easy integration into the vehicle’s electrical system. The primary function of a wiring harness is to organize and protect the electrical connections, ensuring efficient and safe operation of the vehicle’s electrical components 2.

Role of the 3053042 Wiring Harness in Truck Operation

The 3053042 Wiring Harness plays a specific role in the operation of a commercial truck by providing a structured pathway for electrical signals and power. It connects various electrical components, such as sensors, lights, and control units, ensuring they receive the necessary power and signals to function correctly. This harness is integrated with the truck’s engine control unit (ECU), transmission, and other critical systems, facilitating seamless communication and operation 3.

Key Features

The 3053042 Wiring Harness is designed with several key features that enhance its performance. It is constructed using high-quality materials to ensure durability and resistance to environmental factors such as moisture and temperature fluctuations. The harness is engineered to meet stringent industry standards, providing reliable electrical connections. Additionally, it features robust connectors and terminals that ensure secure and consistent electrical contact, minimizing the risk of failures 4.

Benefits of Using the 3053042 Wiring Harness

Using the 3053042 Wiring Harness offers several advantages in truck operations. It improves reliability by reducing the likelihood of electrical faults and ensuring consistent performance of the vehicle’s electrical systems. The harness enhances efficiency by optimizing the distribution of electrical power and signals, leading to better overall truck performance. Moreover, it contributes to safety by providing a secure and organized electrical system, reducing the risk of short circuits and other hazardous conditions 1.

Installation Considerations

Proper installation of the 3053042 Wiring Harness is crucial for ensuring its effective operation. Before installation, it is important to verify that the truck’s electrical system is compatible with the harness. The installation process requires specific tools, such as wire strippers, crimping tools, and electrical tape. Following the manufacturer’s guidelines, the harness should be routed carefully to avoid sharp edges and excessive bending, and all connections should be secured tightly to prevent loose connections 2.

Maintenance and Troubleshooting

Maintaining the 3053042 Wiring Harness involves regular inspections to ensure all connections are secure and free from corrosion or damage. Common issues such as frayed wires or loose connectors should be addressed promptly to prevent electrical failures. Troubleshooting procedures may include checking for continuity in the wires, testing the integrity of the connectors, and verifying that all electrical components are receiving the correct voltage and signals 3.

Safety Precautions

When working with the 3053042 Wiring Harness, it is important to observe several safety precautions. Ensure that the truck’s battery is disconnected before beginning any work to prevent electrical shocks. Use appropriate personal protective equipment, such as insulated gloves and safety glasses, to protect against potential hazards. Additionally, follow all manufacturer guidelines and industry best practices to ensure a safe working environment 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the industry for producing high-quality and reliable components. The company is committed to innovation and excellence, continually striving to meet the evolving needs of its customers through advanced technology and superior product quality 1.

Compatibility with Cummins Engines

The Cummins Wiring Harness part 3053042 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connectivity and performance. This wiring harness is compatible with the K19, K38, and K50 engines, providing a robust solution for managing the electrical systems in these power units.

For the N14 MECHANICAL and NH/NT 855 engines, the part 3053042 also offers a precise fit, catering to the specific electrical requirements of these models. The harness is engineered to handle the unique demands of these engines, ensuring that all electrical components are properly connected and functioning.

Additionally, the V28 engine benefits from the use of this wiring harness, which is tailored to meet the electrical needs of this particular engine model. The harness ensures that all electrical pathways are correctly established, enhancing the overall reliability and efficiency of the engine’s operation 2.

Role of Part 3053042 Wiring Harness in Engine Systems

The 3053042 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating seamless communication and power distribution among various subsystems.

Integration with Accessories

The wiring harness connects directly to various accessories, ensuring they receive the necessary power and signals to operate correctly. This includes components such as the alternator, fuel pump, and air conditioning system. By providing a structured pathway for electrical current, the harness minimizes the risk of short circuits and ensures consistent performance of these accessories 3.

Connection to the Wiring Panel

The harness interfaces with the wiring panel, which acts as a central distribution point for electrical signals and power. This connection allows for the efficient routing of electricity to different parts of the engine system, including the ignition system, lighting, and various sensors. The wiring panel relies on the harness to maintain a secure and organized connection, reducing the likelihood of electrical faults 4.

Interaction with the Engine Instrument Cluster

A significant role of the 3053042 Wiring Harness is its interaction with the engine instrument cluster. It transmits vital data from sensors throughout the engine to the instrument cluster, allowing for real-time monitoring of engine performance. This includes metrics such as engine temperature, oil pressure, and fuel levels. Accurate and timely data transmission is essential for maintaining optimal engine operation and alerting the operator to any potential issues 1.

Support for Engine Components

The harness also plays a supportive role in connecting essential engine components such as the starter motor, ignition coils, and various solenoids. It ensures that these components receive the correct voltage and current, enabling them to function efficiently. This reliable electrical connection is fundamental to the starting, running, and overall performance of the engine 2.

Enhanced Safety and Efficiency

By providing a dedicated and organized pathway for electrical signals and power, the 3053042 Wiring Harness enhances both the safety and efficiency of the engine system. It reduces the complexity of wiring, lowers the risk of electrical interference, and supports the consistent operation of all connected components 3.

Conclusion

In summary, the 3053042 Wiring Harness is a foundational element in the electrical system of engine components, ensuring reliable power distribution and signal transmission across various subsystems. Its integration with accessories, connection to the wiring panel, interaction with the engine instrument cluster, and support for engine components all contribute to enhanced safety and efficiency in engine operations 4.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ ↩ ↩ ↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ ↩ ↩ ↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ ↩ ↩ ↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.