This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3053039 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce electromagnetic interference. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for distributing power and signals to various components, ensuring efficient and reliable operation 1.

Purpose of the 3053039 Wiring Harness

The Cummins 3053039 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects critical components such as sensors, lights, and control modules, ensuring they receive the necessary power and signals to function correctly. This harness plays a role in the overall electrical system by providing a reliable and organized pathway for electrical current, contributing to the truck’s operational efficiency and safety.

Key Features

The 3053039 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear, corrosion, and environmental factors commonly encountered in commercial truck operations. Unique characteristics of this harness include its compact design, which allows for easy installation in tight spaces, and its ability to withstand the vibrations and harsh conditions typical of truck environments.

Benefits

The advantages provided by the 3053039 Wiring Harness include enhanced efficiency, reliability, and safety in truck operations. By ensuring a secure and organized connection between electrical components, this harness contributes to the consistent performance of the truck’s electrical systems. Its durable construction and resistance to environmental factors help maintain the integrity of the electrical connections, reducing the likelihood of failures and improving overall vehicle reliability 2.

Installation Process

Proper installation of the 3053039 Wiring Harness involves several steps to ensure it functions correctly within the truck’s electrical system. Begin by identifying the correct location for the harness within the vehicle, ensuring it is securely mounted to prevent movement and damage. Connect the harness to the appropriate electrical components, following the manufacturer’s guidelines for wire routing and connection. Test the connections to confirm they are secure and functioning as intended. Best practices include using appropriate tools for connections, ensuring all connections are tight, and protecting exposed wires to prevent damage.

Troubleshooting Common Issues

Frequent problems associated with wiring harnesses can include loose connections, damaged wires, and corrosion. To diagnose these issues, inspect the harness for visible signs of damage or wear, test electrical connections for continuity, and check for proper voltage at various points within the system. Recommended solutions may involve repairing or replacing damaged sections of the harness, securing loose connections, and applying protective coatings to prevent future corrosion.

Maintenance Tips

Routine maintenance practices for the 3053039 Wiring Harness include regular inspection for signs of wear, corrosion, or damage. Clean the harness and its connections to remove dirt and debris that could contribute to electrical issues. Ensure all connections are tight and secure, and apply protective coatings as necessary to prevent corrosion. Following these practices helps ensure the longevity and optimal performance of the wiring harness.

Safety Considerations

When working with the 3053039 Wiring Harness, it is important to observe safety protocols and precautions to prevent accidents and ensure compliance with industry standards. This includes wearing appropriate personal protective equipment, ensuring the vehicle’s battery is disconnected before beginning work, and following manufacturer guidelines for installation and maintenance. Adhering to these safety considerations helps protect both the technician and the vehicle from potential hazards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of commercial vehicle operations, contributing to the efficiency, performance, and safety of trucks worldwide.

Cummins Wiring Harness 3053039 Compatibility with Various Engines

The Cummins Wiring Harness part number 3053039 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to meet the specific needs of different engine types, providing a robust solution for maintaining the electrical integrity of the engine systems.

K19, K38, K50 Engines

The K19, K38, and K50 engines benefit from the precise wiring configurations provided by the 3053039 harness. These engines, known for their durability and efficiency, require a wiring harness that can handle their complex electrical demands. The 3053039 harness is tailored to fit these engines, ensuring that all electrical components are properly connected and functioning as intended.

N14 MECHANICAL Engine

The N14 MECHANICAL engine, a staple in heavy-duty applications, is another beneficiary of the 3053039 wiring harness. This engine’s robust design and extensive use in various industries necessitate a wiring harness that can withstand harsh conditions and provide consistent performance. The 3053039 harness is engineered to meet these requirements, offering a reliable solution for the N14 MECHANICAL engine.

NH/NT 855 Engines

The NH/NT 855 engines, known for their versatility and power, also integrate well with the 3053039 wiring harness. These engines are used in a wide range of applications, from agricultural to construction, and require a wiring harness that can adapt to different operational environments. The 3053039 harness is designed to provide the necessary electrical connections for these engines, ensuring optimal performance and reliability.

V28 Engine

The V28 engine, another high-performance engine in the Cummins lineup, is also compatible with the 3053039 wiring harness. This engine’s advanced design and high power output demand a wiring harness that can deliver reliable electrical connections. The 3053039 harness is engineered to meet these demands, providing a robust solution for the V28 engine.

By ensuring compatibility with these diverse engine models, the Cummins Wiring Harness part number 3053039 offers a versatile and reliable solution for maintaining the electrical integrity of various engine systems.

Role of Part 3053039 Wiring Harness in Engine Systems

The Part 3053039 Wiring Harness is an integral component in the electrical architecture of engine systems. It serves as the primary conduit for electrical signals and power distribution among various engine components.

Integration with Accessories

The wiring harness interfaces with engine accessories, ensuring seamless communication and power supply. This includes components such as the alternator, fuel pump, and air conditioning compressor. By providing a structured pathway for electrical currents, the harness enhances the reliability and efficiency of these accessories.

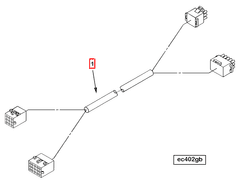

Connection to Extension Harnesses

In complex engine setups, the Part 3053039 Wiring Harness often connects to extension harnesses. These extensions allow for the integration of additional components or subsystems, such as aftermarket performance upgrades or diagnostic tools. The wiring harness acts as the central hub, facilitating the connection and communication between the main engine system and these extensions.

Interaction with Instrument Panels

The harness plays a significant role in linking the engine instrument panel to the engine’s electronic control unit (ECU). This connection enables the display of vital engine metrics such as temperature, RPM, and fuel levels. Accurate and timely data transmission is essential for monitoring engine health and performance.

Support for Engine Instruments

Engine instruments rely on the wiring harness for both power and signal transmission. Sensors such as the oxygen sensor, mass airflow sensor, and crankshaft position sensor depend on the harness to send data to the ECU. This data is critical for the ECU to make real-time adjustments to engine performance, ensuring optimal operation under varying conditions.

Comprehensive Electrical Network

Overall, the Part 3053039 Wiring Harness forms a comprehensive electrical network that supports the functionality of numerous engine components. Its role in maintaining a stable and efficient electrical system is fundamental to the overall performance and reliability of the engine.

Conclusion

The Cummins 3053039 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient operation of various engine components. Its robust design, compatibility with a wide range of Cummins engines, and comprehensive electrical network make it an essential part of maintaining the electrical integrity and performance of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.