This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

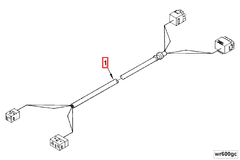

The 3053038 Wiring Harness, manufactured by Cummins, is a vital component in the electrical systems of commercial trucks. Cummins, a well-established name in the industry, is renowned for its high-quality engine and powertrain solutions. This Cummins part is designed to ensure reliable and efficient electrical connections within the truck, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of insulated wires bundled together and often includes connectors, terminals, and splices. The primary function of a wiring harness is to organize and protect the electrical wires, ensuring they are safely routed and securely connected to various components within the vehicle’s electrical system 1.

Role of the 3053038 Wiring Harness in Truck Operation

The 3053038 Wiring Harness plays a significant role in the electrical system of a commercial truck. It facilitates the connection between the truck’s electrical components, such as sensors, lights, and control units. This harness ensures that electrical signals and power are efficiently distributed, supporting the operation of critical systems including engine management, lighting, and communication networks. Its integration with other components and systems is crucial for maintaining the truck’s functionality and performance 2.

Key Features of the 3053038 Wiring Harness

The 3053038 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors commonly encountered in commercial truck operations. The harness is engineered to withstand the vibrations and harsh conditions typical of heavy-duty applications. Additionally, it features precise connectors and terminals that ensure secure and reliable electrical connections.

Benefits of Using the 3053038 Wiring Harness

Utilizing the 3053038 Wiring Harness offers several advantages in truck operations. It contributes to improved efficiency by ensuring that electrical signals and power are transmitted with minimal loss. The harness enhances reliability through its robust construction and high-quality components, reducing the likelihood of electrical failures. Moreover, it plays a role in safety by maintaining consistent and secure electrical connections, which is vital for the proper functioning of safety-critical systems 3.

Installation Considerations

When installing the 3053038 Wiring Harness, it is important to consider compatibility with the specific truck model and its electrical system. Proper installation involves following manufacturer guidelines to ensure that all connections are secure and that the harness is correctly routed to avoid damage from moving parts or environmental exposure. Attention to detail during installation helps maintain the integrity of the electrical system and ensures optimal performance.

Maintenance and Troubleshooting

Maintaining the 3053038 Wiring Harness involves regular inspections to check for signs of wear, corrosion, or damage. Best practices include cleaning connectors and terminals to ensure good electrical contact and protecting the harness from physical damage. Common troubleshooting tips include verifying connections, checking for continuity in the wires, and addressing any signs of wear or damage promptly to prevent electrical issues.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its comprehensive range of engine and powertrain solutions. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance components. The company’s product portfolio includes engines, transmissions, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking.

Cummins Wiring Harness 3053038 Compatibility with Various Engines

The Cummins Wiring Harness 3053038 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connectivity and optimal performance. This wiring harness is engineered to fit the following engines:

K-Series Engines

- K19: This harness is compatible with the K19 engine, providing essential electrical connections for smooth operation.

- K38: The K38 engine also benefits from the 3053038 wiring harness, ensuring that all electrical components are properly connected.

- K50: The K50 engine is another model that can utilize this wiring harness, facilitating efficient power distribution and control.

N-Series Engines

- N14 MECHANICAL: The N14 MECHANICAL engine is designed to work with the 3053038 wiring harness, ensuring that all electrical systems are properly managed.

- NH/NT 855: This harness is also compatible with the NH/NT 855 engine, providing the necessary electrical pathways for the engine’s operation.

V-Series Engines

- V28: The V28 engine is another model that can be equipped with the 3053038 wiring harness, ensuring that all electrical components are correctly connected.

The Cummins Wiring Harness 3053038 is meticulously designed to ensure compatibility and reliability across these diverse engine models, providing a robust solution for maintaining electrical integrity and performance.

Role of Part 3053038 Wiring Harness in Engine Systems

The Part 3053038 Wiring Harness is an integral component in the electrical system of engine setups, facilitating the connection between various electrical components and the engine’s control systems. Its primary function is to transmit electrical signals and power efficiently across the engine system, ensuring seamless operation of all connected devices.

Integration with Accessories

The wiring harness plays a significant role in connecting engine accessories such as alternators, fuel pumps, and air conditioning compressors. It provides the necessary electrical pathways for these components to receive power and communicate with the engine control unit (ECU), allowing for optimal performance and functionality.

Wiring and Panel Connections

In the context of wiring and panel connections, the Part 3053038 Wiring Harness serves as the backbone for the electrical system. It links the engine’s wiring to the vehicle’s electrical panel, ensuring that all circuits are properly connected and protected. This setup is essential for maintaining the integrity of the electrical system, preventing issues such as short circuits and ensuring that all components receive the correct voltage.

Engine Instrument Communication

The wiring harness is also responsible for connecting the engine’s instruments, such as the tachometer, speedometer, and various gauges, to the ECU. This connection allows for real-time data transmission, enabling the instruments to display accurate readings of engine performance metrics. The harness ensures that the ECU can monitor and adjust engine parameters based on the data received from these instruments, contributing to efficient engine management.

Overall System Efficiency

By providing a structured and organized method for electrical connections, the Part 3053038 Wiring Harness enhances the overall efficiency and reliability of the engine system. It reduces the risk of electrical faults and simplifies the process of diagnosing and repairing electrical issues, making it a fundamental component in the maintenance and operation of engine systems.

Conclusion

The 3053038 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks, ensuring reliable and efficient electrical connections. Its robust design, compatibility with various engine models, and integration with engine accessories and instruments make it an essential part of maintaining vehicle performance and safety. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.