This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

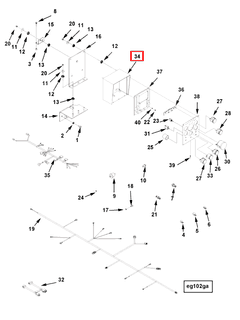

The Cummins 3053010 Instrument Cabinet is a specialized component designed for commercial trucks. It serves as a housing unit for various instruments and controls that are integral to the truck’s operation. This cabinet is significant as it centralizes the monitoring and control of critical systems, ensuring that drivers have immediate access to vital information and controls.

Purpose and Functionality

The Cummins 3053010 Instrument Cabinet plays a role in the operation of a truck by providing a centralized location for instruments and controls. It integrates with the truck’s electrical and monitoring systems, allowing for the display of engine performance metrics, fuel levels, and other operational data. This integration ensures that drivers can monitor the truck’s condition in real-time, facilitating informed decision-making and proactive maintenance 1.

Key Features

The Cummins 3053010 Instrument Cabinet is characterized by its robust design and the use of high-quality materials. It is constructed to withstand the rigors of commercial truck environments, including vibrations, temperature fluctuations, and exposure to the elements. The cabinet features a durable exterior, often made from corrosion-resistant materials, and an interior designed to protect sensitive electronic components. Additionally, it is equipped with ergonomic mounting options and secure fastening mechanisms to ensure stability during operation 2.

Benefits

The 3053010 Instrument Cabinet offers several benefits. It enhances accessibility to instruments, allowing drivers to quickly check vital signs of the truck’s health. The cabinet provides enhanced protection for sensitive components, shielding them from physical damage and environmental factors. Furthermore, by centralizing controls and displays, it contributes to overall truck efficiency, enabling drivers to operate the vehicle more effectively.

Installation Process

Installing the Cummins 3053010 Instrument Cabinet involves several steps to ensure proper integration with the truck’s systems. Prerequisites include ensuring the truck’s electrical system is compatible and that the installation area is prepared. Tools required may include drills, screwdrivers, and wiring tools. Best practices involve following the manufacturer’s instructions closely, securing all connections, and testing the system post-installation to confirm functionality 3.

Maintenance and Care

Regular maintenance and care of the Cummins 3053010 Instrument Cabinet are vital for ensuring its longevity and optimal performance. This includes routine cleaning to remove dust and debris, periodic inspection of the cabinet’s integrity and connections, and addressing any signs of wear or damage promptly. Additionally, staying informed about potential upgrades or modifications can enhance the cabinet’s functionality and compatibility with evolving truck systems.

Troubleshooting Common Issues

Common issues with the Cummins 3053010 Instrument Cabinet may include display malfunctions, connectivity problems, or physical damage. Troubleshooting steps involve checking electrical connections, ensuring the cabinet is securely mounted, and inspecting for any visible damage. If issues persist, consulting the manufacturer’s guidelines or seeking professional assistance may be necessary to diagnose and resolve more complex problems.

Cummins Corporation Overview

Cummins Corporation is a leading manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration systems, and components like the 3053010 Instrument Cabinet. With a history of innovation and a commitment to quality, Cummins has established a strong reputation for producing reliable and high-performance parts that contribute to the efficiency and durability of commercial vehicles.

Compatibility with Various Engines

The Cummins Instrument Cabinet 3053010 is a versatile component designed to integrate seamlessly with a range of Cummins engines. This part is engineered to provide a robust and reliable interface for engine monitoring and control, ensuring optimal performance and ease of maintenance.

K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series lineup, known for their durability and efficiency in various applications. The 3053010 Instrument Cabinet is compatible with these engines, offering a centralized control unit that simplifies the management of engine parameters.

M-Series Engines

The M11 MECHANICAL engine, part of the M-Series, is another engine that benefits from the 3053010 Instrument Cabinet. This engine is widely used in heavy-duty applications, and the instrument cabinet provides essential monitoring and control features.

N-Series Engines

The N14 MECHANICAL engine, a prominent member of the N-Series, is also compatible with the 3053010 Instrument Cabinet. This engine is known for its power and reliability, and the instrument cabinet enhances its operational capabilities.

NH/NT Series Engines

The NH/NT 855 engine, part of the NH/NT Series, is another engine that integrates well with the 3053010 Instrument Cabinet. This engine is designed for high-performance applications, and the instrument cabinet supports its advanced features.

QSK Series Engines

The QSK19 CM500 engine, part of the QSK Series, is compatible with the 3053010 Instrument Cabinet. This engine is known for its power and efficiency, and the instrument cabinet enhances its operational capabilities.

V-Series Engines

The V28 engine, part of the V-Series, is another engine that benefits from the 3053010 Instrument Cabinet. This engine is designed for heavy-duty applications, and the instrument cabinet supports its advanced features.

Role of the 3053010 Instrument Cabinet in Engine Systems

The 3053010 Instrument Cabinet is an integral component in the orchestration of various engine systems, ensuring both the protection and efficient operation of sensitive instrumentation.

In conjunction with the Belt Guard, the Instrument Cabinet provides a secure environment that shields the delicate gauges and controls from potential damage caused by moving engine parts. This partnership is essential for maintaining the integrity of the readings and controls that the Instrument Cabinet houses.

When integrated with the Enclosure and Instrument Panel Enclosure, the Instrument Cabinet forms a robust barrier against environmental factors such as dust, moisture, and vibrations. This enclosure is not merely a physical barrier but also a facilitator of a stable operating condition for the Engine Instrument Panel and Instrument Panel Assembly.

The Engine Instruction Top-Level Assembly Panel relies on the Instrument Cabinet to present a clear and organized interface for operators. It ensures that all instructions and readings are displayed in an accessible and protected manner, enhancing the usability and safety of the engine system.

The Instrument Panel and Instrument Panel Enclosure work in tandem with the Instrument Cabinet to provide a comprehensive monitoring solution. The Cabinet supports the Panel by offering a structured layout that allows for easy access to controls while maintaining a clean and uncluttered workspace.

Furthermore, the Instrument Panel Mounting and Instrument Panel Panel are supported by the Instrument Cabinet, which provides the necessary structural support and spatial organization. This allows for a more intuitive and ergonomic design of the engine’s control interface.

Lastly, the Panel Engine Instrument and Panel Instrument components are directly influenced by the Instrument Cabinet’s design. It ensures that these panels are not only protected but also optimally positioned for both visibility and accessibility, contributing to the overall efficiency and safety of the engine system.

Conclusion

The Cummins 3053010 Instrument Cabinet is a critical component for commercial trucks, offering a centralized location for instruments and controls that enhance the monitoring and operation of the vehicle. Its robust design, compatibility with various Cummins engines, and integration with other engine systems make it a valuable asset for ensuring the efficiency and reliability of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.